-

Posts

1051 -

Joined

-

Last visited

-

Days Won

9

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Chickenman

-

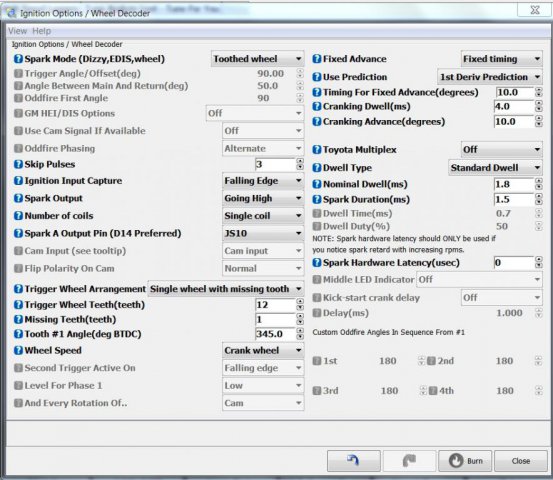

May have found something. Nominal Dwell in Ignition settings may be too low. Was set at 1.8ms in tune you downloaded. Guy may have been using a fast saturation coil like a Crane E-Coil. Should be around 3.0 ms for a standard coil ( Canister oil filled ) Pull the coil dizzy lead, crank it over and see how strong of a spark you get with setting at 1.8ms. If it is very weak it is likely the dwell is too low. If you have a good spark then leave it alone If spark is weak, change " Nominal Dwell " to 2.5 to 3.0ms. Start off low then slowly add time ( .2ms per change is good ) . Burn and cycle ignition. Then repeat spark quality test. Spark should be much stronger now. Coil saturation times vary greatly. Older style coils tend to be slower charging. You don't want to go too high though, as you can over heat the Coil and the Coil Driver ( BIP373 ) Spark duration of 1.5ms should be fine. DIY has an article on the BIP373 where they discuss coil dwell. They have a simple method to check if you've gone too high with dwell. The BIP373 do have built in thermal protection, so they won't burn out. They'll simply shut down. Here's the link to the article and the pertinent excerpt from the article: https://www.diyautotune.com/support/tech/other/bosch-bip373-ignition/

- 83 replies

-

- megasquirt

- ems

- (and 5 more)

-

That sentence was why I thought the Fuel Pump was not working. Never mind the question about the Spark Output. Using D14 was on one of the drop down menu's in Decoder Wheel settings... but I think it's a misprint. All other MS Extra instructions say to use JS10. Edit: Confirmed it's a misprint in drop down menu. Archived Instructions for older build used D14. The 12v wire to the Dizzy CAS assembly handles milliamps. You don't want to run the trigger wires close to higher amperage 12v wires such as the injector 12v feeds, the ignition coil 12v lead or any main 12v power leads. That can give cross talk.

- 83 replies

-

- megasquirt

- ems

- (and 5 more)

-

I set the high and low values in relevant columns, then use the Interpolate function to smooth all values in between.

- 83 replies

-

- megasquirt

- ems

- (and 5 more)

-

Just looked at Data Log from post #43. Looks like a whole bunch of electrical noise is going on. Edit 1: Looks like no injector Pulse either. Was engine running with this data log? Edit 2: MerloZ . Just curious. What are you using for a coil driver? Some sort of external module, CDI box or does your MS2 have the optional BIP373 coil driver. If BIP373, shouldn't spark output be on D14???

- 83 replies

-

- megasquirt

- ems

- (and 5 more)

-

Could be some sort of hardware issue going on as well.... Juts thinking out loud and trying to think of what would cause misfires. Are trigger wires from dizzy routed well away from HT leads and coil? Also trigger wires should not be run parallel or zip tied to any 12v wire. Can cause signal noise. Ignition boxes ( if your'using one ) should be mounted well away from ECU. CDI boxes like MSD are particularly bad for EMI.

- 83 replies

-

- megasquirt

- ems

- (and 5 more)

-

No worries man. I'm certainly no genius. At 17 you are doing great. It's a long process. I'm 63 and still learning every day. Regarding no fuel pressure after last test. Walpro 255's draw a LOT of amps. You may have blown the FP fuse or even the factory FP relay. Factory relay can't handle the amps that a Walpro draws. You usually have to wire in a 40 Amp Continuous Duty Bosch relay. Use genuine Bosch relay as some of the aftermarket stuff is junk.

- 83 replies

-

- megasquirt

- ems

- (and 5 more)

-

Ignition Table. MerloZTune3.msq Again conservative with added timing a low load cruise but safe overall values at high RPM and under Boost. Note 500 RPM value higher than 1,000 RPM . That is done on purpose. Anti-Stall feature which most OEM manufacturers use in addition to IAC valve. 2D Ignition Table: 3D Ignition Table:

- 83 replies

-

- megasquirt

- ems

- (and 5 more)

-

In case any one wants to take a gander, here are the AFR tables that I built. Pretty conservative, with cruise and low load cruise to be around stoic. Idle is always set a bit richer than stoic. As soon as the boost starts coming in I throw the fuel at it. 11.0 AFR is going to be nice and safe under boost. Should be fine for much higher boosts than he will be initially running. MerloZTune3.msq 2D Fuel Table: 3D Fuel Table:

- 83 replies

-

- megasquirt

- ems

- (and 5 more)

-

And see, I did miss post #22... cause I'm old and frequently post way too early in the morning. Yeah.. I went through all the fuel maps and ignition maps and corrected all the errors in the general settings. It's now a 2.8 liter motor with 260CC Turbo injectors. Garbage In... garbage out. A permanent fuel pressure gauge is a must have as SJ mentions. All the tuning in the world won't fix a hardware failure like a faulty FPR. Do get a Fuel gauge tee'd in there somehow, even if just for temporary use. You have to confirm the exact Fuel Pressure or all the fancy calculations goe out the window. An aftermarket FPR will be needed somewhere down the road, as I trust you will eventually be turning up the wick. Lack of CTS and having the warm-up enrichment enabled ( which was also scaled way too high ) would also make it Pig Rich. That was one of the biggest problems in your original tune. To OP: Don't tune by VE tables or change their values. You leave those alone ( once set correctly ) . You tune by altering the AFR tables. I've built you a good AFR table right off the bat. It will be safe and should run smoothly. Don't muck with it too much.... unless I built a pile of dog poo.... which I don't think I did. Same with the Spark Maps. I have idle set at 15 BTDC for a good reason ( Anti-Stall ), Car will run fine with that setting and Tune is built around it.

- 83 replies

-

- megasquirt

- ems

- (and 5 more)

-

Tremec TKO Sequential Clutchless Shifting?

Chickenman replied to 260DET's topic in Gen III & IV Chevy V8Z Tech Board

I had a race ( many moons ago ) when the clutch slave cylinder failed after a couple of laps. Small bore Datsun with a synchro box. Very small and lightweight gears and synchro's. Very fast shifting for a synchro box. Ran whole race with no clutch pedal. Downshifts were easy, but upshifts were a PITA. A slower shifting box would have been even worse... FWIW. -

Tremec TKO Sequential Clutchless Shifting?

Chickenman replied to 260DET's topic in Gen III & IV Chevy V8Z Tech Board

Biggest problem is the synchronisers. Race transmissions don't have synchronizers, they have dog rings. Really hard to make it work with synchronizers. If you want clutchless upshifts and downshifts, you may want to look at a used racing Jerico 4 or 5 speed with proper dog rings. And TKO trannies aren't the fastest shifting around ( due to slow synchronisers and heavy gears ), so it makes what you want to do doubly hard. As far as auto Rev up on downshift, your Haltech may be able to do that... but really, the easiest way is to train your right foot. Here's a video of James Courtney ( Aussie V8 Super Cars ) and his heel and toe technique. These are sequential shift dog boxes, but James is a right foot braker and likes to use the clutch on downshifts. It's not necessary to use the clutch at all with these gearboxes, but it is easier on the box. These guys know how to Heel and Toe properly!! https://www.youtube.com/watch?v=P1ZuynAYMLo&list=PLTlMnJOh8l3Y3F1-6AWvU0H8NGYXSQAvg&index=3 -

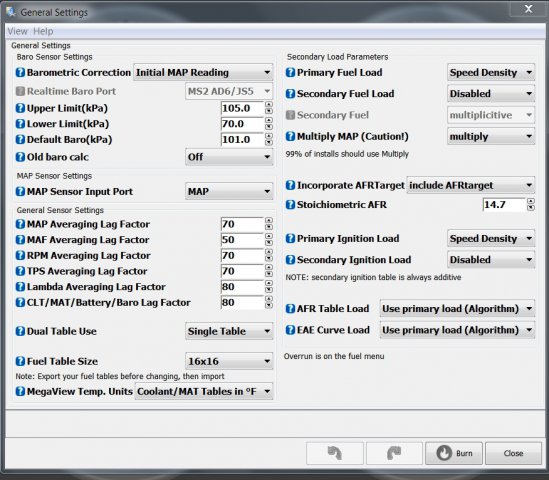

Here's the latests Tune file with startup enrichment mellowed out a lot. BTW, if the plugs are looking like lumps of black coal, throw some fresh plugs in. They're cheap and you can't tune on fouled plugs. And get that Coolant Temperature sensor hooked up. And the AFR Wide Band feed to the MS ECU. I've enabled the AFR feedback feature in my tunes, so hook it up please. It will make your life a lot easier. Note: If you have a problem with hooking up the Innovate AFR gauge auxiliary output to the MS, then disable " Incorporate AFR Target " under the " General Settings " tab:

- 83 replies

-

- megasquirt

- ems

- (and 5 more)

-

I'm going to make up another Tune file with Warm-up enrichment disabled. I have to change the warmup map to do this. Normally you do not want warm up enrichments being enabled when you are doing a base tune. And I think the Warm-up map from the original file you downloaded is too rich. Edit. Not running a Coolant Temperature Sensor was probably the main reason why it ran pig rich. A CTS is one of the main sensors that the ECU uses to determine fuel flow. Most Tuning software allows you to easily enable or disable compensation MAPs via a check box, but MS does not have this Option. So I'll just make another .msg file with the Warm up map disabled. I'll call it MerloZTune3.msq and post it up in a ZIP file..... after I have my morning coffee. Keep plugging away. But don't try and over think things. Follow the DIY instructions and you'll make progress. Still ask questions, that's how you learn... but understand that DIY has done some software programming outside of " Normal " conventions to make their " Funky " Nissan trigger wheel work. You don't have to understand " Everything " all at once. It's a huge learning curve and will take time. Do yourself a favor and order DIY's EFI Tuning book from their Webstore if you haven't already bought it. Cheers. BTW... I'm retired and have been racing for over 40 years. That's how I have the time to work on this stuff. I like helping people out, but sometimes spend way too much time at the keyboard. I often post at the early hours of the morning ( Insomnia ) so sometimes I miss things cause my brain's a bit foggy...

- 83 replies

-

- megasquirt

- ems

- (and 5 more)

-

I'm sorry...but I've read this thread over several times and I've yet to see where you mentioned that you were running 6.8 psi. Maybe I missed something?? Unless you mean the sentence: " I have a pretty much stock 82 l28et ". That may mean one thing to you.. and something entirely different to another person. Regardless, when someone asks you specific questions, over the Internet, please try to answer them plainly and clearly. We are not there, and we could be visualizing something completely different from you. And assumptions can lead to mistakes. As Slowpoke mentioned, read up some more on the " Trigger Offset Wizard " to understand why you lock in the Timing at a set degree ( 10 Degrees is just what MS uses as a default ) and synchronise your Trigger Angle Degree to your timing light. Once you get your timing light synched to that figure, you switch back to " Use Ignition Table ) and the timing will adjust to what's in the table. Note: I built you a safe Ignition ( and Fuel ) Table just to get your car up and running SAFELY. By no means is it a final tune . It's a baseline that should have your car up and running smoothly and safely. You ( or I ) can can tweak things later. 15 BTDC at idle will work just fine for now... The following " Novel " is to help you understand the difference in old school mechanical dizzy timing control s and new ECU controlled timing: In a normal "Old school " dizzy, with mechanical and vacuum advance, the trigger sensor ( Points or electronic pickup ) is physically moved to set the initial timing point. You " twist " the dizzy. The points or reluctor pickup also sits on a moving breaker plate. That also physically moves by mechanical or vacuum mechanisms to physically advance the Ignition timing. In a ECU controlled system, the crank sensor is normally locked in one position. It cannot ( usually ) be physically removed. Instead we rely on Electronics to move the Timing point. Here's something that will help you understand ECU controlled Timing. ECU Ignition timing can never be " advanced" . Unless you break several laws of the space and time continuum. What an electronic system does is actually retard or delay the timing. The crank sensor is usually placed 60 to 70 degrees BTDC. The reason for this is that it has to be above maximum cruise total advance ( This can be 45 to 50 degrees BTDC under light cruise modes ) .... and you have to allow for some extra overhead because the electronics do take some time to do the calculations. It's in milliseconds, but at 7,000 rpm a few milliseconds can be quite a lot in crank degrees travel . In summary. With an ECU controlled timing, lets say you want 10 degrees of idle ( static ) timing. Let's say Crank sensor is located at 60 degrees BTDC. When ECU senses the trigger signal, it " Delays " the coil firing by 50 crank degrees. 60 -50 = 10 Easy Peasy. At high RPM's you want more spark advance so the EDCU " Delays " the signal less. 60 - 25 = 35 BTDC. Note that the crank sensor number doesn't change. That number ( once it's calibrated or synchronised ) never changes. Nissan incorporated the crank sensor in the Optical dizzy and yes there is a small amount of adjustment allowed, but it is not meant to be used as a " Timing adjustment " . It can be used for something called " Rotor Phasing "... but that is well and truly above your level of understanding right now and is of little significance. Set the Dizzy adjustment in the middle and then leave it alone. Now... DIY uses a very " Funky " trigger wheel for use with with Nissan Optical Dizzy's. You don't have to understand the reason why ( It has to do with limitations of there firmware coding ) but they've designed a very strange wheel. That's why you see some truly bizarre setting under " Decoder Wheel settings" . IE: A trigger offset of 345 degrees instead of a more normal 60 or 70 degrees. And the wheel is actually a 24 -1 -1 wheel. But in the settings you select 12 - 1. A couple of other things to. TRUST me. you don't have to understand why they did it ( unless you're a budding software engineer ) only THAT IT WORKS!! So follow the DIY instructions completely. Another thing. Do not take someone else's file and use it on your engine " Just because it worked ".... on the other guys engine. How do you know his Optical dizzy isn't bolted down a bit different than yours? How do you know that he may have his oil pump/dizzy drive spindle off by a tooth? Calibration of the Trigger Offset is critical. So learn how to do it properly and calibrate it to your engine. However, It just may happen that 240 degrees or 250 degrees is pretty much close to what your engine requires as well. So keep that in the back of your head.

- 83 replies

-

- megasquirt

- ems

- (and 5 more)

-

OK. This is the Tune i've built as a safe startup for Merlo's 280Z Turbo. I've done the best that I can without being there. This should be a good and safe baseline. Remember NO MORE THAN 5 lbs of BOOST!!! ( for initial tuning ) 1: Download the following .zip file and extract the .msq file to your Desktop. 2:: Start a new Project from Tuner Studio or open an existing Project A project is basically a book to load various Tunes into. 3: Load the MerloZTune2.msq file from within Tuner studio. 4: Disconnect all injector terminals or switch Fuel pump off. 5: Go to Ignition Settings menu and select Ignition Options/ Decoder Wheel. Change the " Fixed Advance " button to " Fixed Timing ". Fixed Timing is locked at 10 degrees BTDC. Attach timing light to engine and a battery charger ( or fully charged battery ) 6: Have your helper crank the engine over while you look at the timing mark. Adjust Tooth #1 Angle until you see timing light mark line up at 10 BTDC. You may need a second helper to adjust computer while you do this. When Trigger angle setting lines up with 10 BTDC on your timing light, hit the burn button at the bottom. Then Cycle ignition off and back on. 7: With ignition back on, go to Ignition Settings menu again, Ignition Options/Decoder Wheel, and change the " Fixed Advance " button to " Use Table ". Hit the Burn button. Then cycle Ignition off and back on. 8: Connect all Injector terminals or turn fuel pump back on. 9: Cross your fingers and toes and Start her up!! If everything has been done correctly it should light off and idle reasonably well.

- 83 replies

-

- megasquirt

- ems

- (and 5 more)

-

This article has some very good information. Be sure to read it thoroughly: http://atlanticz.ca/zclub/techtips/turbo/

- 83 replies

-

- megasquirt

- ems

- (and 5 more)

-

Once you get it up up and running with a base tune, Log with Tuner Studio to your Laptop. Data logging is one of the most important things in tuning. Laptop has to be connected. Time to do some more reading at MS forums. Log ignition timing, AFR ( ASAP, hook your LC2 auxiliary WB output to the proper MS input ), Manifold absolute pressure, RPM, coolant temp as a minimum. You do have the factory FPR hooked up correct? I would recommend getting an Aeromotive #13129 EFI FPR. Summit and Jegs carry them. https://www.summitracing.com/int/parts/aei-13129 Run it in bypass mode. Summit and Jegs carry them. You will need the ability to control adjust fuel pressure down the road. Stock FPR runs at 37.5 PSI. That's pretty low pressure. Mots injectors run at 3 BAR ( 43.5 PSI ) Higher fuel pressure allow you to run injectors at a lower durty cycle when you get into higher boosts. You want to keep IDC under 85% if you can. You should consider switching to a Pallnet Fuel rail for ease of installation. See our Vendors forum. Still waiting for answer on these questions. BTW, what are you using for a boost controller? MS Boost controller, Auxiliary Electronic Controller or Manual Boost Valve? Will work on the Tune file a bit tonight... your current posted one is a mess.

- 83 replies

-

- megasquirt

- ems

- (and 5 more)

-

Too late to the party, but GM sells a temp sensor that is 12mm x1.5 thread pitch. Screws right into the stock L28 housing. Maybe pick up a new or used L28 lower stat housing and start over. I'll look up the part number a bit later. Edit: Standard Blue Streak part number for 12mm x 1.5 GM CTS is TX89. OEM GM part # is 15326388 or 15369305 . I would recommend ordering genuine GM sensor or AC Delco ( Delphi brand ) as the sensor calibrations are bang on with these. Aftermarket brands vary in specs quite a bit. Your LC2 wide band should be connected to your MS. Get that handles as Chris ( I think it's Chris?? ) mentioned. It will make tuning so much easier. Working on an improved Tune file for you that should be a safe running baseline. You will still have to set your Trigger offset properly and set timing. This should get you up and running but it is in no way a final tune. Log everything, especially AFR and do not raise boost above 5 psi, until Tune has been further refined. I take no responsibility for what this tune will do to your engine. Use at your own risk. But I've made it fairly conservative. Look it over for any glaring faults before using. Will edit post and upload tuning file later in the day. BTW, what are you using for a boost controller? MS Boost controller, Auxiliary Electronic Controller or Manual Boost Valve?

- 83 replies

-

- megasquirt

- ems

- (and 5 more)

-

Scca E Prod slick size

Chickenman replied to plygasser47's topic in Brakes, Wheels, Suspension and Chassis

Goodyear G19 Radial Cantilever. 23.0 x 9.0 -15 Purpose built for E-Prod . Cantilever sidewall tire made to fit on 7" E-Prod rim. available in both Dry and Rain tires. http://www.racegoodyear.com/tires/pdf/Goodyear_Sports_Catalog_2015.pdf -

Any cam experts? Colt Cams adv duration vs @0.05"

Chickenman replied to turbogrill's topic in Nissan L6 Forum

DatsunParts won't sell you a split set? Did you call them? -

The 310 CC Supra injectors should be good. Fit our Intake manifolds and have an 11mm top O-Ring to fit a PalNet fuel rail. Bottom 2 seals not shown but same as our Z lower seals. http://www.ebay.com/itm/291075192985?_trksid=p2055119.m1438.l2649&ssPageName=STRK%3AMEBIDX%3AIT

-

Swapped in a 363... lol too much power??!

Chickenman replied to thedarkie's topic in S30 Series - 240z, 260z, 280z

The R1R's are available from Tire Rcak in a 225/45x16 and recommended rim width is 7" to 8.5". I'd go with the 45 seriers as I think a 225/50x16 is going to be too tall for your stance. -

VigLink is back. Just tried posting a link to Tire Rack for a member asking about DOT Tires and got re-directed by VigLink. Here is the link to Tire Rack that I tried: https://www.tirerack.com/tires/tires.jsp?tireMake=Toyo&tireModel=Proxes+R1R&sidewall=Blackwall&partnum=44WR7PR1RV2&tab=Sizes

-

Swapped in a 363... lol too much power??!

Chickenman replied to thedarkie's topic in S30 Series - 240z, 260z, 280z

This will solve the problem. But... not without a bit of cutting. Nice though. https://www.ztrix.com/fender-kits/280yz/ https://www.ztrix.com/280yz-kits/madlangbayan-280yz.html -

Swapped in a 363... lol too much power??!

Chickenman replied to thedarkie's topic in S30 Series - 240z, 260z, 280z

Lot of guys in the PNW are running DOT- R compound tires on the street. Yokohama 048 or 050's are very popular. These are very lightweight cars with some pretty good power to weight ratios. Turbo guys are pushing 250 to 275 RWHP in 2,000 lb cars. BFG rivals are also a very sticky tire and come in lots of sizes. Looks like you're running some sort of 3 season tire now? DOT -R compounds will make an amazing difference. Some of the DOT tires are " Cheater " sizes. So a 225 is more like a 235 or 245 in actual width. BTW, Toyo R1R's are really sticky and really wide for their stated size. The 245/40x17 should handle your Power without having to cut the sheet-metal. They have a lot of sizes in this tire. It's often overlooked Edit: What size rims do you have now?