-

Posts

13742 -

Joined

-

Last visited

-

Days Won

67

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by JMortensen

-

What brand is this Triple Carb intake?

JMortensen replied to wickiewicked240z's topic in Non Tech Board

Looks like Mikuni to me. No crossover tube, 2 towers with teflon bushings rather than 3 rod ends for the linkage. Looks shorter than my old Cannon manifold. Try Todd @ WCR. He would know for sure. -

How much cam is needed for the F54/E88 combo?

JMortensen replied to Mycarispurty's topic in Nissan L6 Forum

The 73 E88 is a boat anchor. There is nothing good about that head. It's an open chamber NOx reduction design. I'd suggest you find a P79 or a P90 and run that, and maybe shave it if you don't want 8:1 compression. I ran a .020 over F54 with dished pistons with E31 and it ran fine on 89 (I think it would have run fine on 87 too). Then I rebuilt it with flat tops, compression was about ~11:1 with the different valves that I had installed, and it pinged like crazy with the .490/280 cam that I had. I mixed race gas with pump to figure out what it needed to stop pinging, turns out it was 95 or 96 octane. If I had to do it again, I'd much rather run an engine at 8.x:1 or shave it for 9:1 or 9.5:1 and then run it on pump gas. Especially if it is a daily driver. There is more power in being able to run the timing at the right spot than there is in the extra point of compression, plus you won't be driving down the road wondering "Did I just hear a ping?" all the time. FWIW, I'd ditch the DGVs too and pick up some early roundtop SUs. -

Race prep mods to the shell - 1970 240z

JMortensen replied to Nismodealer's topic in S30 Series - 240z, 260z, 280z

I'd suggest you post up your cage design before you start welding it in. Just take pictures and draw it out in paint, or use the chassis dimensions schematic which I think is in the downloads section. We have some pretty smart guys here who have some nice cages and might be able to help get the design optimized. Are you running in a particular class, or just a track day car? I'd think venting the hood would be better than putting holes in the fenderwells. Depending on the cage you might even be able to take out large portions of the fenderwell in addition to hood vents. Is this going to be driven on the street too, or trailer only? Have you seen 74_5.0L_Z's car? It's not a bad place to look for ideas... -

Woodward power steering project

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

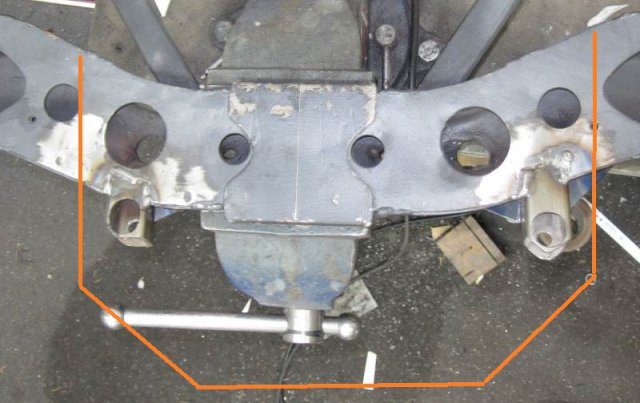

Got the linkage and everything done, so yay for that. Turns out the steering shaft fit without having to notch the frame rail. Steering linkage is all done. Still need to mount the ps pump and get hoses made for it, and do a quick release for the wheel, but the hard stuff is done. Then went to bolt up the sway bar. Boo. Turns out the hydraulic cylinder hits the bar when I turn right. Will have to relocate the sway bar mount forward and lengthen the arms which will make the bar weaker. Shouldn't be too hard. I have the sway attached to a rod end, so I made a new tube to weld through the frame with a nut on the end to thread the rod end into. The end of the bar also hit my droop limiters, so will probably figure a way to limit droop with the sway bar as well. Got a bar from a 280Z that I bought earlier this year, so I'll have 2 bars to fit up and make work. On the plus side, looks like this setup gives a lot of room for exhaust. -

hood vents: ideas...

JMortensen replied to OlderThanMe's topic in Windtunnel Test Results and Analysis

Are you having cooling issues? If you remove the air dam, you'll reduce pressure on the top of the splitter. I'd keep it there unless there is a real need to do otherwise. -

Extracting seized bleeders

JMortensen replied to SleeperZ's topic in Brakes, Wheels, Suspension and Chassis

MAPP gas torch? I've never had any luck heating fasteners with propane. -

Can't post attachments so I sent you an email screenshot. superdan@hybridz.org, right?

-

Fender Vents, General aero Questions

JMortensen replied to Challenger's topic in Windtunnel Test Results and Analysis

Me too. Don't think it's working as of right now. You can link to photos stored elsewhere, but can't add them as attachments here anyway. -

ITS guys crack the uprights at the top, and they're just using them to locate the suspension and they're limited to near stock size wheels. The front mount should control lifting of the nose, the rear has to control the twisting. The twisting is a big deal, which is why the stock mustache bar is thick spring steel and wide.

-

You're not actually planning on running it just like that with the diff bolted to the uprights, are you? You need to make a MUCH stiffer assembly to bolt the diff to. Have a look at blueovalz's rear plate that he made, or some of the diff mounts from tssfab.us, the various V8 miata mounts, etc. If you put power to that you're going to fold it like a wet napkin.

-

My Dream LS7GTZ.......project underway

JMortensen replied to cobramatt's topic in S30 Series - 240z, 260z, 280z

Would be curious to hear more on the suspension issues. Never liked the way the upright bolted to the strut on the new design, or the lower control arm setup that you already fixed either... -

Rustoleum roller job, what about urethane air dam?

JMortensen replied to scooterhulk's topic in Body Kits & Paint

If you brace the top, you're going most of the way across. Here is bjhines' car: http://forums.hybridz.org/index.php/gallery/image/6316-black-240z-full-frontal/ A rad duct is the next thing to consider, just read more in the aero section on that if you're interested, but this would support the airdam just fine and would make it a lot more functional in terms of downforce than not having a brace. -

Some info on noises. LSDs only work when you're turning, so this sounds like it's not an LSD problem. Based on the below, probably a pinion bearing. Looks like my links didn't work. There are two diff noise pages off of this link: http://www.ringpinion.com/TechnicalHelp/HowTo.aspx

-

Rustoleum roller job, what about urethane air dam?

JMortensen replied to scooterhulk's topic in Body Kits & Paint

Came in here because I'm doing the rustoleum thing too and haven't gotten to the airdam yet, although mine is FG so I don't really anticipate any problems. Not entirely sure I'm following what you guys are talking about with respect to how you intend to brace your dams, but a lot of people find that they sag in the middle over time. I think it's better to brace it with a piece of sheet metal at the top and have that brace run back to the rad core support than to brace it with sheet at the bottom. Bracing it at the top makes an air dam more effective in that it gives a spot for the low pressure area behind the dam to act on. Bracing at the bottom reduces drag but also makes the airdam less effective because the flat area on bottom no longer sits behind the dam which is what causes a strong low pressure area. You can still get some downforce there by virtue of the air speeding up, but you won't get the total effect of the dam. If you wanted to brace the bottom edge because the air dam was flapping at high speed for example, you could make supports to go from a sheet on top down to the edge and this would be the best of both worlds - until you hit a parking stone. Try and find bjhines' example. Might be in the wind tunnel area. He does nice work. -

How much caster is safe with poly bushings?

JMortensen replied to Sideways's topic in Brakes, Wheels, Suspension and Chassis

I think you can run quite a bit safely but the issue is more that the poly bushing will be bound up pretty hard by the TC rod, so you're increasing stiction and stress on the crossmember. Get TTT's LCA or something similar and you'll solve that problem. As far as what needs to be changed, you'll probably run out of room at the front fender if you get past 5-ish degrees. If you run a whole lot of caster, you may run out of room on the turnbuckles and might want to install longer ones. The rule of thumb is 1.5x the thread diameter inside the turnbuckle, which on a 5/8" turnbuckle leaves you with about 5/16" of adjustment. I think most people tend to ignore the rule of thumb for that reason. Check TC rod clearance with the wheel at full lock as well. Depending on your backspacing you might have issues there too. -

Woodward power steering project

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

Yeah, that's it. 5" of scrub and a lot of caster means a lot of lifting, and the quicker rack means you can load it one way and then the other faster, which I'm likely to do with an autox car. -

Woodward power steering project

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

I called Woodward and talked to Tony, and that's what I ended up with. Cobramatt also has a Woodward rack in his crazy roadrace car. Not sure what process he went through to pick one, but I believe he has the same thing I do. Just looking at the catalog, it appears that the MR isn't made in a ratio as fast as I wanted, and I remember talking to Tony about the 13" wide front wheels and autoxing and he thought I needed the high load rack because of the stresses. I'm not seeing a real clear description of how it mounts, but I think it's going to be similar. My real problem was that I was trying to move the rack as far back as possible which was going to cause issues with the crank pulley and I had my mounting tube in the wrong orientation. Once I figured that out it wasn't that bad, just one of those measure 47 times, weld once sorts of deals. -

Woodward power steering project

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

That's a damn good idea, as usual. Thanks! -

Woodward power steering project

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

Got the rack mounting done, welded and gusseted and ready to rock. Still not sure about the skid plate idea. It looks like the aluminum housing that holds the hydraulic cylinder is also hanging down about 1/4", same as the rack mounting square tubing. That pinion housing is about 3/4" down. Still considering whether or not to do a skid plate. I have a bunch of 1" square tube, so I could build a little frame and then weld a 1/8" plate to it and that would give clearance. Biggest problem is that the plate is heavy. I could just weld a section of square tube to the bottom of the crossmember on each side and then hope that the hyd cyl doesn't get whacked before the crossmember bottoms. Or I could have the square tubes sticking out off of the front like a spear. At least that way I could have them extend under the cylinder to give more protection without gaining all that weight... -

Being that it is a 3.54 and those are common (almost every manual 280Z had one) I'd just go find another one. Don't swap the ring gear either. Take the ring gear off and use the ring gear from the next 3.54 you get.

-

Woodward power steering project

JMortensen replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

Back on this one. If there is one part of my build that has held me up more than anything, this is it. Stared at the mount that I had been planning on using for about a day and then cut it in half and decided to make two posts that stick out off of the front of the crossmember like the stock horns. The Woodward rack isn't symmetrical, so there was much hemming and hawing getting the thing centered on the crossmember. Finally just tacked a couple of 3/4" by 1/8" straps to the crossmember just to get the positioning correct. Once that was done I took a couple 1.25" square tubes and tacked them on to see what it looks like when it is all done. Moved the rack forward to make more clearance for the crank pulley. After having an argument about Ackerman with Leon I charted out the Ackerman and found that at full lock moving the rack as far back as possible made about 1 degree of difference. Not worth the hassle. This position moves the rack to parallel with the steer knuckles, so gives parallel steer. I'll just run a buttload of toe out. After seeing how little difference it made, making room for the pulley was a bigger concern than maximizing the tiny amount of Ackerman I could get. I didn't think I was going to be able to use the attached servo on the rack, but detaching it and getting the rack situated it looks like it will fit, just barely. Might have to notch the frame rail for clearance for the steering shaft. Other option is to run the servo remote and have 2 shafts. Trying to avoid that as it is yet more fabrication. Looks like my pinion housing will be about 3/4" below the crossmember, and the front of the hyd cylinder will be at about the crossmember height. Question now is what to do about that. Thinking about building the crossmember lower and making a skid plate to protect the cylinder. I'd hate to ruin a rack because I drove over a curb at the track and smacked it on the ground, and this car will be low. -

hood vents: ideas...

JMortensen replied to OlderThanMe's topic in Windtunnel Test Results and Analysis

You don't need 100% of the rad opening to get the air out. The air flowing over the hood will help to suck it out. If you look at the Ford Focus rally cars of a couple years ago for example they have some very oddly shaped exaust tubes going to fairly small openings in the hood. The hood openings look kind of like the 70's Dodges with a 2" tall slit that is maybe 10 or 12" long. I prefer 74_5.0L_Z's exhaust as it has a closed tunnel in and out of the car, that means that the air doesn't have to "find" the vent, but if you did this you would probably see a huge improvement over stock. -

Yet another Rear control arm design

JMortensen replied to tholt's topic in Brakes, Wheels, Suspension and Chassis

5.3L aluminum V8 from a 2006 GM truck. Cam and springs should put it at ~350 whp-ish and 400 ft/lbs. Yes, thank you for the rails John. Working on the front crossmember to get the ps installed now. Really would like to see it run in 2013. Tired of autoxing a basically stock Miata. The Miata handles pretty damn well for what it is, but it is too slow!!! -

I love the 8.8 idea (cheaper, ratios from 2.72 to 6.16, LSDs, lockers, spools, 31 spline axles, etc) and I hope you get it done and it turns out well. FWIW, the Ford trak-lok LSD kinda sucks. You might be able to shim the crap out of it to get it tight enough, but it isn't a torque sensing LSD like the Nissan unit. It's a sprung clutch unit. Seems like you're really just drag racing. You might look at a detroit locker, or even a spool. Spools are cheap and that's as strong as it gets. Don't know if they have one with the grooves machined for the axle circlips. Might be possible to do that machining after the fact.

-

Yet another Rear control arm design

JMortensen replied to tholt's topic in Brakes, Wheels, Suspension and Chassis

No bar. I'm going to try some insanely stiff springs and a smaller front bar. If I can't get the balance right then I'll mod the rear arms for a bar. I do have a bar and I have nice brackets to install it to the rear uprights, so it won't be as bad as doing it from scratch if I end up needing it.