AydinZ71

Members-

Posts

1073 -

Joined

-

Last visited

-

Days Won

27

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by AydinZ71

-

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

We’ll never mind on the bearings haha. Looks like my shop is going to source custom thickness bearings based on the Dims of the rods, crank, and block journals 🤷🏽♂️ learn something every day! -

Nah the spacer is there to give you the strut travel you need. it lowers the hub to a level where you have sufficient droop. If the strut travel is too short, you will lose contact patch with the pavement on your inside tire when taking tight turns. Without the spacer, your control arms will be completely horizontal, with zero droop. Basically, when you lift the car you will wonder “huh… why doesn’t the suspension drop”. But yes, with the spacer in there you just need the tube to terminate with enough length to get that gland nut in. Make sure you estimate it well so you get several engaged threads before it makes contact, and not so little that the nut bottoms out before making contact with the insert. I made a silicone gasket on top of my insert to cushion when tightening the gland nut on, but that’s optional. Where your lower spring perch goes is entirely dependent on your length of spring. Mine are 10”, but if yours are different you will need to figure out your own perch height.

-

The rear strut tubes require a 2” spacer to be placed inside the tube. Then the finished height of the tube is however tall it needs to be for the cartridge to slide in and the hand nut to secure the Insert. First time around I didn’t realize I needed a spacer, so I had to go back and add material. The fronts don’t need the spacer, so it’s just however long they need to be for the hand nut to work. i believe the distance from the cast portion of the strut (bottom of the tube) to the bottom of the spring landing was 7” in the rear, and 5” in the front.

-

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

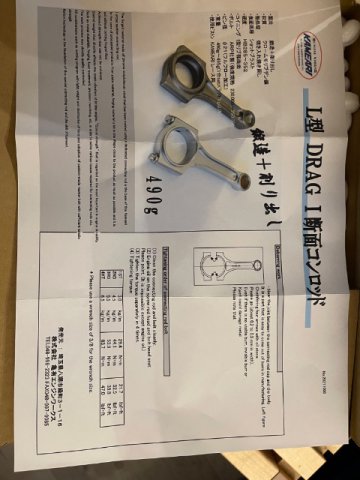

Hello friends! I will start with the question first: What are you using for main and rod bearings for your L-series race engines? Should I just source OEM Nissan bearings? Kameari sells bearings too. Now for some show-and-tell. My rods came in, so I wanted to share with you the parts going into the 3.1L race motor. Sourced from Kameari direct from Mori-San. Rods are 137.5mm, or 4.5mm longer than the usual L24 rods used. Will yield a higher rod-ratio than sourcing OEM rod length and piston deck being. They are 490g, which are lighter than anyone else’s published (pre-engineered) rods I could find. Racing pistons are forged w/ 3.2cc valve pocket volume. Deck height matches with rod length for a near flush deck. 88.5mm also going to try out the infamous chain sprocket to replace the tensioner. N42 is with Yoes doing his magic. 11.5:1 so I can get fuel from my local 100 octane pump. -

IMSA GTU vintage racer build

AydinZ71 replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

That's exiting man! She's starting to look like a car! -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

I will send you a message! -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

@clarkspeed cool! Which direction? I’m landing at 6am Saturday in Orlando and renting a car. My guess is 8am at Daytona. Come on down! If you are on the way to/from I’d be happy to stop by! -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Alright folks, I went ahead and purchased the OEM exedy clutch. I really evaluated what I needed this for, and realized I was tying myself in knots. This clutch is for me to get the car around town while I tune the suspension and motor, so clearly I was over thinking it. I have the 5.5” for competitive racing, and should keep that in mind. I looked into the ACT HD and XD Pressure plates and they were twice the price of the whole OEM kit including disk etc. I will likely purchase the HD PP for the 3.1L which will be a good compromise until I consider a 7.25” unit for that motor. Not much as far as updates. Been two months of travel, COVID, and work so looking forward to getting back in gear. Finishing the rear lower valence filler work at the moment. Still have the drivers side lower quarter, both doors, and both fenders left. Then can finally spray and start reassembly. I was planning to be in Daytona for Greg’s HRS race this Friday but had an important client request that day. Taking the red-eye to spend the weekend with him for the 24hr historics instead. -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

100% agree on the dual or heavy duty PP being more than enough for any NA L-series. I'm surprised to hear you like the sprung disk. Maybe I could give it a try and see how it goes. It just always felt "squishy" to me when I was shifting quickly, especially at lower speeds. It was really evident when the car had a change in momentum as well, for instance going from downshifting to getting back on the throttle. Maybe the heavy spring rate and suspension had more to do with it, and the sprung clutch was just adding to an already "squishy" chassis/suspension. -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Thanks guys! I had the same experience Jon. I’m glad it wasn’t just me. I had a 6-puck on the 300ft-Lb L28et, and it started losing grip from all the material removed on the flywheel. Not from the actual pucks themselves wearing. You are the first person who I ran across that had the same experience. Clearly the hardness of the flywheel’s friction surface was inappropriate for the aggressive disk material. I also switched to what the clutch shop called a “double” PP, and an unsprung “street” disk material. -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

hey thanks Clark! Il have to look into that for the next motor. I’m assuming the 7.25 comes with it’s own dedicated crank mounting surface (not really a “flywheel” I suppose)? Any ideas on what I should run with the 9lb OEM diameter flywheel? I was just going to default to an Exedy OEM clutch unless someone had a suggestion. This is for the interim period before the car is competitive. Ideally I’d get an unsprung disk, but I don’t really need anymore torque capacity than what OEM offered. Saving the 5.5 for the meantime. -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Yep! Greg basically told me not to slip the clutch if I could help it. With that said, don't drop it at high rpm either. Like you said Jon, short engagements at low RPM just to get it rolling. When you think about it, there really isn't a means for the clutch to wear if you are rev-matching and out of first gear. Its slipping just enough to absorb the drivetrain shock between gear changes, and no more. 4.75"! That is wild!! Heck if you can get by push-starting it, you don't even need the auto-trans ring gear either! Ok, unrelated (you said rev like a super bike) but I am super excited to get my Kameari rods for the 3.1L (not EP)! They are stuck in customs up in Alaska, but I already have the forged pistons in-hand. They were the lightest set of pistons/rods with the largest rod ratio of any manufacturer I could find, short of commissioning something completely custom. This engine is two years in the making. -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

It is a 5.5" with two disks. True story, I told Greg Ira I planned to run the 9lb flywheel and asked for his advice on a clutch. He laughed at me, and said "you are kidding, right?" and shipped me his identical spec (he just added +qty 1 to his order). I want to say it was around $1200. I could ask him the details, but I think he was pretty protective (at the time) about disclosing too much. As he said to me "you know how long it took me to settle on this setup?". On-track he said it would last two seasons as long as you are rev-matching and baby-it in first gear. -

My V07 crank was off by 5 thou. Had it straightened for $200 by a "magician" (best way to describe it). Based on your selection of rods (rod ratio), it does not strike me that you will be using this motor for racing so you might be OK. Does not sound like you will be spending much time at higher RPM's. But honestly, I am happy to pay the $500 in labor for my local experienced machine shop to be doing the work you are attempting. Just peace-of-mind. They have much more knowledge, experience, and the proper tools that go well-beyond what the "how to rebuild" and "how to modify" books can provide (and I have read both several times). This is coming from a mechanical engineer, too. I certainly respect you doing it by yourself! -Aydin

-

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Hi all! It has been a while. I was in Europe for two weeks, than had COVID which knocked me out for another two weeks. Finally getting back to the car. For competition, I have a button flywheel/clutch combo from quartermaster sitting on my shelf. They wear pretty quick if you are doing any street driving or stop/go. I'm looking for a clutch I can use for off-competition tuning and getting it to and from places. Will also use it for track days until I get the suspension tuned. I have a Kameari 9lb flywheel in the OEM formfactor I plan to use. I was going to just default to an inexpensive OEM spec Exedy clutch, but was curious if ya'll had any recommendations. I steer-clear of all the BS clutches that are marketed at "stages". In the past I would order custom clutches with un-sprung disks and dual diaphragm pressure plates (my L28et), but the shop has since gone out of business. The L24 as built today wont put out more than 160-170ft-lbs, so not much need for grip. -

I have seen many, many 280zx parts cars on FB over the past two months. You could take a photo of the spot you wish to replace and ask if someone is willing to cut that portion out and sell it to you. I would post in an FB Z group as a “parts wanted”. Otherwise, if it’s a small enough area without a unique contour, I’d just make it out of mild steel sheet and use body filler to contour.

-

+1 on how you will drive the car as described above. For road racing, the torque a 3L put out will be OK on the diff. That is for SUSTAINED (low impulse, no shock) torque on a light vehicle, where rev-matching between gears is standard process. A lightweight flywheel/clutch will already require you to baby the launch, as those clutches wear out fast. If you are launching with sticky tires and dropping clutches drag-race style, no... It will likely fail during a launch one day. Even an R200 may get dicey launching on grippy tires. Impulse breaks driveline components well before sustained steady-state stress. I learned this the hard-way by destroying a handful of R200's before I realized my driving style was the biggest culprit. Also, the CLSD having wearable parts will obviously require maintenance as a weak point, but I am not familiar which of the two center-sections (CLSD vs. helical) has more shock resistance. I have a 17' STI helical LSD in my car. It is inoperable 🤣

-

I think the listing disappeared Just going to whine for a brief moment. Having returned to FB for the first time in many years, the Datsun/Z enthusiast groups on there are…. Disappointing…(except for the racing specific groups) Reading the responses to folks asking for help. Man, you really got to sort through some terrible responses/advice before you find anything pointing in the right direction (if at all).

-

Silly question Clark. I have a 180deg thermostat in my Setrab oil cooler/filter sandwich plate. Is that enough to avoid blocking the cooler on a cool day?

-

ZCD is out of stock, but I think I see a few for $175 on eBay. Pretty expensive for a piece of machined brass but when you are the only one and volume is low…. Kameari sells a worm drive gear as well, but the details are sparse. Il shoot Mori an e-mail about it when my rods are nearer to completion.

-

And where can this magic bronze gear be found, if I can hazard to ask? 😅😂 haha

-

IMSA GTU vintage racer build

AydinZ71 replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

@clarkspeed all good Clark! I think you shared a photo way-back-when, at least I remember seeing it. The idea is to feed the center of the hat/hub just like you said. Some dynamic pressure from the headlights helping get the air to the hub, and the centrifugal force from the spinning rotor/vanes do the rest, woohoo. Il fabricate something out of sheet metal once I get the car rolling. Gotten pretty good at fabricating small, light custom stuff out of sheet metal. I think il try some of the 20-gauge stainless I have on hand. Nozzle will be a 3” sectioned tube. -

@tube80z Makes a lot of sense to utilize all sorts of functions if you have a PDM. I looked into the AIM units a while back but I still need to learn to drive, let alone data analysis/utilization haha. Saving grace is all my gauge sensors are electronic (even the 2” gps speedo) so I can use the data in the future beyond just the autometer gauges. Good idea to remote-mount the oil pressure sensors. Not sure I can do the same with the oil temp sensor since I’d prefer to nab the reading straight from the oil pan. @clarkspeed ahh so you also did the pressure switch triggering a light! Glad I’m not way off base. I have a local indicator gauge on the accusump too, but the whole unit is remote mounted in the engine bay. sorry about digressing from your post Ben!

-

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Thanks Cary! Indeed, pretty limited in EP. I kinda like it though, keeps me from going off-the-rails with too many crazy ideas until I can get some actual track experience (whenever that will be). Il keep going I decided to give the Skillard air dam and splitter combo a try. Speaking with them, I may be the first person trying it out on a (hopefully) competitive car. I have some aero changes in mind, but the biggest seller for me was the splitter already ends where my EP rules require it to. I think I could have fabricated something similar, but I’m really trying to stop the immediate inclination to fabricate everything. My read of the GRC makes it acceptable, as it does not depart from the overall “envelope” of the car. Hood remains the furthest-forward body panel. It’s also lower than the conventional fiberglass/urethane units so I may not need a front-end scraper like Greg had.