NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

I'd guess that it is a 1970 - 1977 Z. Could be a bad regulator. How about some ammeter numbers? "Jumping" is not enough. Even better would be some voltage numbers at the battery. A good opportunity to get some practice with a meter. Good luck.

-

Here's an old halfshaft thread that covers the length, binding, and shortening. Might be the best of what's out there.

-

The halfshafts are all the same, even the 280ZX shafts. One of the Hybridz members compared a range of years and determined that, but, unfortunately his web page with the data is gone. The 240Z's seem to be slightly narrower between the wheel flanges than the 280Z's, but that has not been confirmed. It's not the halfshafts, it's the cars. The binding issue doesn't seem to be a big problem but you can find threads about people grinding areas of the halfshafts to shorten them at full compression. In short, all you really need is the correct pinion shaft flange. Or a 75 280Z propeller (drive) shaft. Or, maybe there's a flange that you can swap on to your 240Z shaft, see link below. I haven't gone through the actual measurements so don't know for sure if this guy's parts work. Some of his information is wrong, like the part about the 79-83 differentials. 76-83 R200's all have the same dimensions, I have had several across the full range. I've also seen square flanges (78) and circular flanges (76) that fit the same way. Shape does not correlate to fit. Anyway, worth some measuring. Check the bolt hole diameters. Make sure the u-joints will fit. Good luck. https://jagsthatrun.com/products/adaptor-flange-for-datsun-z-v8

-

Is the R200 from a 1975 280Z? They had an odd flange size. The other 280Z R200's will swap over directly. Your original 240Z driveshaft should work with those. The R180 and the R200 are the same length. The 75 280Z R200 flange is an oddball.

-

What engine is going in?

-

Twin cam head for the L6 from Derek at Datsunworks

NewZed replied to Derek's topic in Nissan L6 Forum

You guys went for the troll's bait. Tiny tiny win for zboi. -

-

The topic has come up before. Might be something in the attached link. There are probably others. Compare the holes in the head with the holes in the block, and to the holes in the gasket. You might find that the different gaskets will flow the same amounts.

-

-

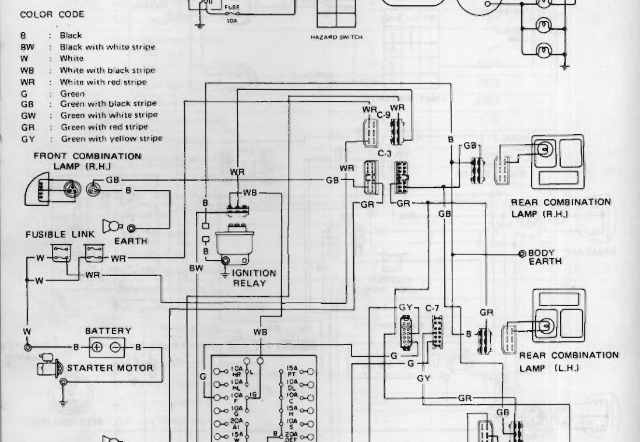

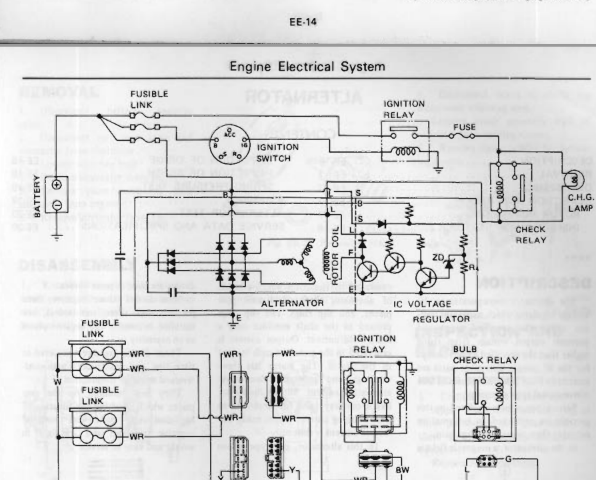

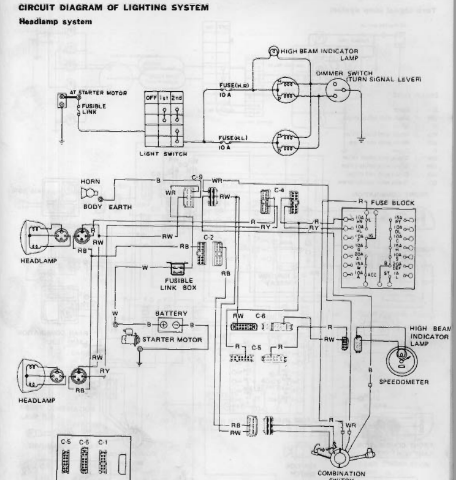

I would use the Engine Electrical and Body Electrical chapters for the diagrams. They are more detailed. I don't see the ignition relay involved in the lighting system.

-

MSD ignition install replace hitachi transistor ignition

NewZed replied to Toddman's topic in Nissan L6 Forum

Here are some links to how to wire up an HEI module if you decided to try it. You can do it all from the engine bay, no need to get inside the old module. It is just unplugged. I think that you might have to join to download the full documents, but the thumbnails have the schematic. Used to be free over there but now there's a charge. There are old posts on the forum about it too though. Good luck. https://www.classiczcars.com/files/file/64-1977-280z-replacing-the-tiu-with-a-hei-module/ https://www.classiczcars.com/files/file/124-instruction-fitting-a-4-pin-hei-module-to-280z-1977-revdpdf/ -

MSD ignition install replace hitachi transistor ignition

NewZed replied to Toddman's topic in Nissan L6 Forum

Have you already bought the MSD box? A GM HEI module will do the job too and be cheaper. The MSD boxes have been known to be difficult. Sometimes they work, sometimes they don't. Sometimes they work but the tachometer stops working. You would want the MSD instructions for the "magnetic pickup". Two wires. That's what the Hitachi system uses. Actually, there are a few tests that you should do to make sure that the pickup coil is working inside the distributor. The pickup coil can go bad. The air gap can be wrong. If it's broken the MSD box won't work anyway. -

1978 Datsun 280z No Acceleration Above 4000 RPMs

NewZed replied to Kad77's topic in S30 Series - 240z, 260z, 280z

Clogged exhaust system comes to mind also. Especially if it has a catalytic converter. -

Looks like they might be available in Japan. https://www.carpartsmanual.com/datsun/Z-1969-1978/power-train/differential-gear/r180 https://www.google.com/search?q=38154-78501&rlz=1C1SQJL_enUS862US862&sourceid=chrome&ie=UTF-8 https://www.amazon.co.jp/NISSAN-ニッサン-日産純正部品-ADJUST-38154-78501/dp/B091Z23WNM

-

There's some good information in this old thread -

-

1978 Datsun 280z No Acceleration Above 4000 RPMs

NewZed replied to Kad77's topic in S30 Series - 240z, 260z, 280z

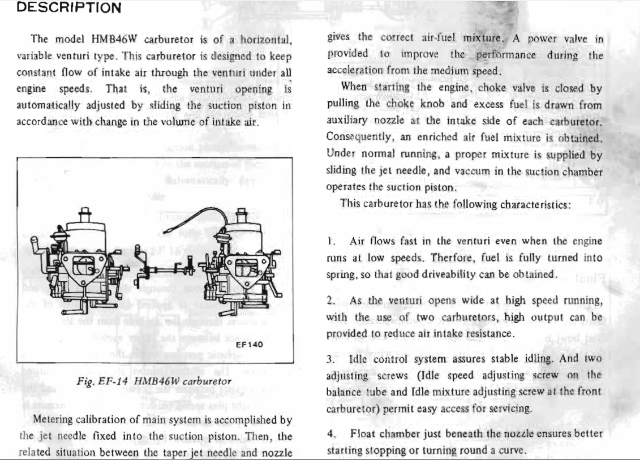

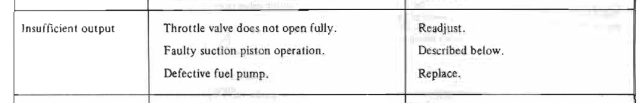

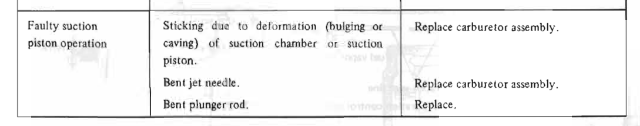

Probably worth your time to study up on how the SU's work. They're not your Dad's Buick's carburetor. Air flow is controlled by vacuum. Seems like your "suction pistons" might not be rising fully, choking off air flow. This from the 1973 Engine Fuel chapter - -

Spindle Pin Set Screw - Needed or not?

NewZed replied to calZ's topic in Brakes, Wheels, Suspension and Chassis

Don't overlook the fore and aft movement. The bushing sleeves and bolt length and nuts and washers all need to be considered. There are no clear exploded views of how all of the parts there fit together. You kind of have to mental it all together. -

Spindle Pin Set Screw - Needed or not?

NewZed replied to calZ's topic in Brakes, Wheels, Suspension and Chassis

What's the bore size of the T3 parts? With a tight tolerance and some grease it becomes more of a bushing type application. I think the original pin is 16 mm. 5/8" is loose. 5/8" = 0.625" = 15.87 mm The lock pin allows the bushings to perfom their spring action with vibration damping, and also keeps the arm legs (?) connected if the nuts come off. If you switch to the PU bushings there's rotation inside the bushing anyway. If I was using a 5/8" bolt I'd probably just safety wire the nuts or create a flat and use a peenable nut. Just for peace of mind. Just some thoughts. A bolt and some threadlocker and you'll probably never notice a difference. -

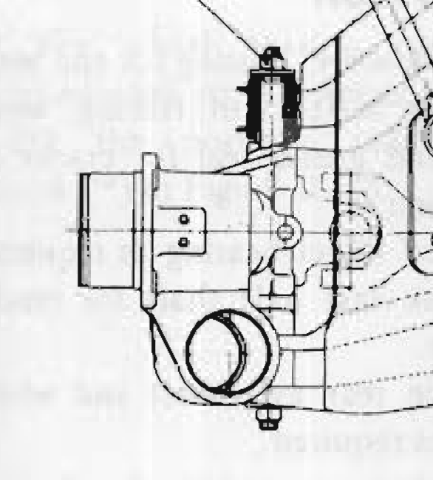

Can't tell from your pictures if the brackets are swapped. The engines have a tilt to them with proper installation. If the brackets are swapped I think that it does bring the left side up, making the top of the valve cover more level. It can look correct but be wrong. The simplest way to tell might be to check the bottom of the oil pan. It should be level from left to right. Hate to say it and maybe, subconsciously, you already know it but it looks like that custom intake manifold could also be the problem. Where did it come from? Good luck.

-

Make sure you get a 280Z mustache bar to use with that 280ZX R200, it's needed. And the half-shafts if you don't have the clip-in style. Not clear what you're starting with. The other part of your "old posts" problem is parts availability. They're not as plentiful as they used to be. The 5 speeds and the R200's and the required mustache bar are getting harder to find. You can go aftermarket on the mustache bar but it's expensive. Finding parts might be your decision-maker. A junker 280Z might be a good way to get the parts. Good luck.

-

These words don't make sense. The valve cover is hitting the intake throttle body? Not sure what the effect is but sometimes people get the left and right engine brackets switched. I know it changes the angle of the engine. Not sure about height. Parts 6 and 7. https://www.carpartsmanual.com/datsun/Z-1969-1978/engine-280z/engine-mounting

-

Replying to FAQ's - Dat73z

NewZed replied to NewZed's topic in Brakes, Wheels, Suspension and Chassis

It will be interesting to see how things hold up. Are you using MIG welding? I assume that you are but you didn't say. There should be warping at each weld spot which might affect bearing wear since the inside of each cap is essentially a bearing race. Besides loss of heat treatment. Not trying to be negative, just assessing the odds. Good luck. -

@Dat73z If you wanted some discussion about your recent post you'll have to post in a non-FAQ section. People can post new stuff in FAQ but nobody can reply. It's been this way for years, not clear why nobody fixes it or at least adds a note to new posters. You didn't say which u-joints were "too soft". That would be helpful.

-

Don't overlook the shield.