NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Does it have other markings on it besides F149? Might help the sale. Various manufacturers make Torsen type differentials. Spin the ring gear and you'll probably find something. Also, what car was it meant for? The 1975 280Z's had a different propeller shaft flange pattern. Just curious and good luck.

-

Looks like a 1975 - 1977 280Z engine. The N42 head and block. A common engine swap, all of the L24 parts fit. Any chance the original L24 is still around, back in the weeds somewhere? It might add value. Not to send you away from Hybridz but classiczcars.com is a better fit for that car and what you're doing.

-

Have you checked each injector's circuit? Power supply and continuity back to the MS board? If you have power supply and connection on the grounding side on all injectors at the board then your thought that the board is messed up is probably right. You probably know this but the injectors spray when the computer supplies a ground to the injector circuit. Voltage is always present at the injectors when the key is on, but they only spray when the circuit is grounded and current flows through the injector solenoid. There are several ways to check the circuit. At least you're making progress. p.s. the engine still should have started, then died, with ether. You might still have a problem after fixing the injector situation. One problem at a time though...

-

p.s. forgot one of the other big EFI problems that often catch people - intake system air leaks. Leans out the mixture and also kills the sensor signal to the computer. The computer adds fuel based on the air flow it is told is happening. Might even be a bad MAP signal. Signaling no air, meaning 'no fuel necessary". Or a shorted temperature sensor showing a hot engine, which also means less fuel needed. I'd go through the whole cold start sequence and look at what the computer needs to know. Make sure it's getting good information.

-

I would try starting fluid again. It's not satisfying as far as puzzle-solving, it feels like cheating, but it really will tell you if the spark is happening at the correct time, and the intake system is open. If you have a remote starter and a can of starting fluid you should be able to run the engine for minutes all by yourself. On a cold engine it's not a big deal, it won't hurt it. On a warm one you can get some detonation so don't overdo it. Beside that, don't overlook the exhaust side. Any chance the exhaust system is blocked? The air has to be able to flow all the way through. You said all you did was install a turbo. Turbo is part of exhaust.

-

Here's a basic that often catches people - maybe you have the ignition timing set to the exhaust stroke. The flash of your timing light. The timing mark on the damper pulley passes the pointer twice - once on compression and once on exhaust.

-

If you have spark and timing is right it should start on starting fluid and run for a second. Not just a sputter but a solid burst of RPM. Any chance you left a rag in the intake tract? Could there be a blockage somewhere? Are you using a MAP sensor? Have you had a spark plug out and rechecked it? Maybe you're adding too much fuel and gas-fouling the plugs. Those are big injectors. Just some ideas. Get back to the primitive aspects of the engine. Fuel, air, spark.

-

It might help to describe more about the engine itself. When did it last run? Have you done any work on the engine? Your focus is on the MS system but maybe it should be on the engine.

-

Any chance that you have the plug wires installed in backward rotation? That would give proper timing on #1 but the others would be off. Although, I have started an engine with the plug wires that way. It ran terribly. Here's your old thread with the msq file.

-

The power to the chip would come through the trace on the board. It's hard on the eyes but you can follow the trace back to its source. You might find a burn mark or a cut. The board might not be ruined if you find something. People repair circuit boards. If you put the board together yourself then the odds of a wrong/bad solder are higher, I'd guess. I'd go back and check my work. By the way, you can buy inexpensive transistor testers. No idea which are good or not. Even Harbor Freight's cheapo multimeter has one. Really though, if there's no power on the board trace even a good transistor won't work right. Not an expert... Just for fun - https://www.harborfreight.com/electrical/electrician-s-tools/multimeters-testers/7-function-digital-multimeter-59434.html

-

How are you measuring power at the transistor? Are you probing the board? Did you pick the correct pin? You're in to electronics world now. Here's a couple of links that might help. I've never been in to a Megasquirt board I'm just commenting based on the basics. Maybe you'll see something in the diagram. There's a fuse or two but it seems like the whole unit would be down if it blew. Maybe the BIP373 is damaged, although they say it's very durable in the link I gave above. But in their chip upgrade, linked below, they call it "infamous". Who knows, their description above and the link below are kind of contradictory. Good luck. https://www.diyautotune.com/support/tech/other/grounds/ https://www.diyautotune.com/product/coil-driver-kit/

-

It's not the votage drop that matters it's what the voltage drop indicates. No spark will be created if the current through the coil is not stopped. You could also disconnect the coil negative at the coil and check the wire for continuity to ground, key off. Disconnect the wire, put one meter probe on the end and the other probe on a good bare piece of metal or the engine block. You should get OL or infinite/huge ohms on your meter.

-

Here's some BIP373 stuff in case you haven't seen it. It will shut down automatically if settings are wrong. They give some quick and dirty settings also. https://www.diyautotune.com/support/tech/other/bosch-bip373-ignition/

-

I don't know much about TunerStudio but can you see the coil control signals? In other words does it show that the current is being turned on and turned off? That's what causes spark, the turning off of the current. 11.9 volts is low, implying that the negative side of the coil is grounded. But it should only be grounded through the Megasquirt circuit, no other circuits. You might try disconnecting the connection to Megasquirt and seeing if the coil still has a voltage drop. You might have a short to ground on the negative side of the coil. With Megasquirt disconnected from the coil the voltage should match battery voltage exactly since no currrent is flowing. The other thing connected to the coil negative is the tachometer trigger. A shorted tachometer could cause the problem, for example, although that is unusual. You didn't confirm that the old igntion module is completely disconnected. If the blue wire from the coil is accidentally grounded it will cause a problem like yours.

-

Probably in the manual. It's both 700 and 3000. Good luck. https://static.summitracing.com/global/images/instructions/xr700 instructions.pdf

-

You shouldn't need to snip the resistor for the tach. Might actually be a bad idea. Just disconnect the original module by the fusebox and leave the blue wire connected at the coil so the tach can count sparks. somebody on another forum just had a similar problem. They forgot to disconnect the module but after they did everything worked fine with the resistor on the tach line. Have you looked through the several installation articles out there? I think that the swap to the DIY CAS wheel just make things more likely to work correctly. "More friendly" as DIY Autotune says. Something to keep in mind if you have problems. Good luck. Post a startup video. https://www.diyautotune.com/product/54-mm-optical-trigger-wheel-for-nissan-l28et-or-vg30e/ https://forums.hybridz.org/forum/93-megasquirt/ https://www.diyautotune.com/support/tech/install

-

There is no swap hardware to put the Z transmission behind a V8. It wouldn't handle the torque anyway. The 260Z engine is about 158 cubic inches, compared to 350 for a SBC. The old Z transmission bearings are typically ready to fall apart besides that, not uncommon even with the stock engines. It would probably last about one pull. I haven't done it myself, but I wouldn't even try it just based on what I've learned.

-

Yes, with the carbs you can get rid of the ECU and EFI parts. The complete EFI harness can be removed. The guys that know on the site (from the past) say that the exhaust system is restrictive and opening it up helps a lot (see John C posts from the past) , and that if you decide to use a performance cam go big (see JMortensen posts from the past). The typical "Stage" 1 or 2 cams don't add much, apparently. So, the simple and effective way to add some power is with a better exhaust system and a big cam. Cams are more expensive than they seem because you need to buy lash pads and rocker arms along with the cam. The collection of parts costs can add up. But it's a pretty simple operation to get it done. Many people like the lighter flywheel. It takes more finesse on the clutch pedal but they say it's worth it. Fidanza is a good choice. For street driving an LSD doesn't add much. You might wait on it and see if you have traction problems. There is a ton on the site from the old-timers, around the 2000 to 2015 time range. Things have slowed a lot on the site as people have moved on. But their contributions are still here. Many of the guys were racers and/or engineers/mechanics/machinists and spent a lot of time and money on their projects. Today's car hobbyists really only know turbos and EFI since that's what they were raised on. Good luck.

-

I had both square and round flanges from a 76 and a 78 propeller shaft (what Nissan calls the center longitudinal driveshaft) and a variety of diffs with round and square flanges and they all interchanged. There are definitely different bolt patterns but you can't tell by the shape of the flange. Best to measure. Watch out for the 88 viscous LSD. Different axles. Shiro.

-

77 280Z Scraping/Whirring from rear-end

NewZed replied to atariangamer's topic in S30 Series - 240z, 260z, 280z

The drums might be rubbing on the backing plates. Not uncommon to get a bend in it when working on the brakes. You'll see a shiny spot.- 1 reply

-

- 1

-

-

Bought a non-running 280zx. Looking for advice.

NewZed replied to Akuma_no_S130Z's topic in S130 Series - 280ZX

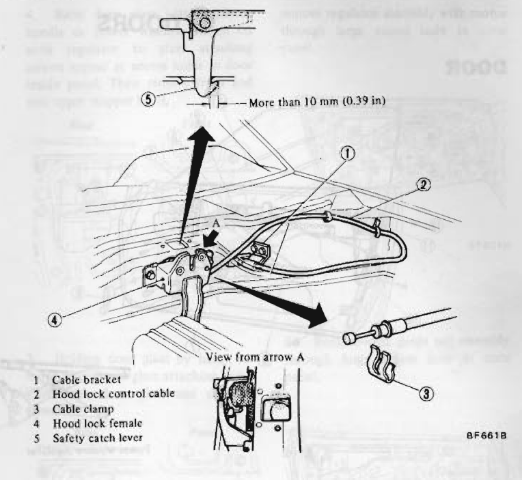

Which end? If the piece in the cabin broke you can use Vise-grips. If the end under the hood broke you'll have to figure something out. -

Help diagnose engine ticking noise 280z

NewZed replied to mehul7's topic in Trouble Shooting / General Engine

Sometimes a rocker arm will just be noisy. Has any work been done on the head? You might check the wipe patterns on the rocker arm wear/rubbing pads. Where the cam touches the rocker arm. It's not uncommon for people to get the wrong lash pads installed. I've even seen where the cam lobe runs off the end of the pad. https://www.classiczcars.com/forums/topic/50485-rocker-geometry-woes/ . . . -

Help diagnose engine ticking noise 280z

NewZed replied to mehul7's topic in Trouble Shooting / General Engine

These overhead cam rocker arm manual lash adjustment engines are naturally noisy. Have you adjusted the valve lash? It's the first item in the Nissan FSM tune-up chapter. By the pictures and video, your lash is certainly not too tight. It looks a little loose, by the extent of the brown on the cam lobes. It doesn't sound terrible. It might even be an injector. You can disconnect the injectors with the engine running to see. Pull the clips so the injector plugs are loose, put the valve cover back on and let it run. Pull each injector one by one and see if anything changes. If the noise is still there after adjusting lash. . . . -

Here's a pasted image. Just for reference, it's not the web site. I think I've seen the -200 error when I tried to upload a certain image format. Might have been a Paint file. Maybe try saving your picture in a different format and retrying.