NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Bought a non-running 280zx. Looking for advice.

NewZed replied to Akuma_no_S130Z's topic in S130 Series - 280ZX

What are your short-term and long-term plans? Should be pretty easy to get it running again if you want to have a driveable project. Give more history about the car. How many miles? How long has it been sitting? "A couple years" probably means ten. When was the last time it ran? If it ran before you don't really need to check cylinder pressures. First thing might be to check the fuel quality in the tank. Don't turn the key on if the fuel is bad the pump will prime some of it through the fuel system. Check the oil for water. Check the air filter and intake tubing for mice nests. Many small things you can do before turning the engine to get a good head start on getting it running again. classiczcars.com also has Factory Service Manuals. Since you're in Utah I wouldn't be so sure about the advice to remove the windshield. You'll know if it leaks after you wash it. No need to create more work for your self unless you know it's necessary. Good luck. p.s. take a video of the engine. We'll see if any parts are missing. -

How to unscrew stuck outer tie rod??

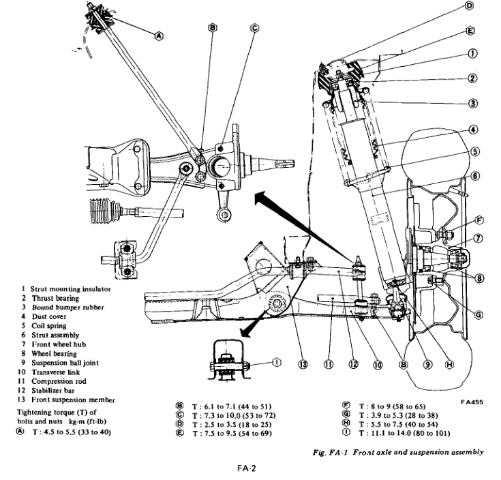

NewZed replied to kaibiagi's topic in Brakes, Wheels, Suspension and Chassis

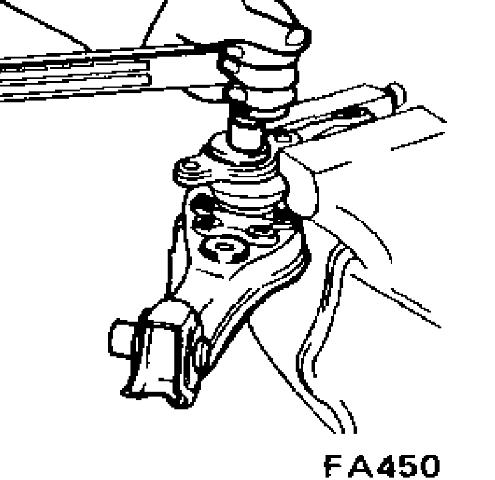

I think that you are right. Surprised that it fits in there the wrong way. Does it actually fit or is it just jammed in? Look more closely at the various drawings and you'll see. -

How to unscrew stuck outer tie rod??

NewZed replied to kaibiagi's topic in Brakes, Wheels, Suspension and Chassis

My experience has been that when the parts are installed correctly you can tell. I'm not even really sure what you're talking about, to be honest. Hard to see how a person could get it installed incorrectly. Post a picture. https://www.rockauto.com/en/moreinfo.php?pk=14663421&cc=1209226&pt=10070&jsn=383 -

How to unscrew stuck outer tie rod??

NewZed replied to kaibiagi's topic in Brakes, Wheels, Suspension and Chassis

-

How to unscrew stuck outer tie rod??

NewZed replied to kaibiagi's topic in Brakes, Wheels, Suspension and Chassis

It's designed to "stick", it's a jam nut. Threads against threads. The last guy probably over-torqued. One trick to get more force on your wrenches without smashing your knuckles or contorting your body or applying force to the rod ends is to set the wrenches up with about a one-inch gap between them and use your grip strength to apply the force. Squeeze them together. Don't get your fingers between them. And if the wrenches are slipping use Vise-grips. Also, don't forget about leverage. Longer wrenches. -

Try explaining that catalytic converters were not used until 1975. The cop might have assumed that the loud exhaust meant that the cats were gone. Take a copy of the Owners Manual and or the FSM pages that show that there is no catalytic converter. Don't talk about anything under the hood. Not a word. Also point out that the car was properly tagged and registered with the equipment the cop cited as deficient. And apologize for your brother's stupidity. https://sciencehistory.org/stories/magazine/clean-machine/#:~:text=Beginning with the 1975 model,%2C nitrogen%2C and carbon dioxide. Three years later the recently created Environmental Protection Agency mandated that all cars beginning with model year 1975 be outfitted with catalytic converters to meet emission standards. Thousands of researchers were put to work by catalyst companies and car manufacturers. General Motors alone, at the time the country’s largest carmaker, put 5,000 people to work on catalytic converters.

-

No, you just pull the bearings off of the front of their shafts. The countershaft bearing is pretty tight to the gear and takes some trickery. The mainshaft bearing needs a puller with long arms. You can push the rods back to get more room. The transmission will have multiple gears engaged but it won't matter. When you reinstall the front case put it in a single gear (one rod moved) to avoid locking up the transmission by accident. Here's a decent video about the countershaft bearing, different tranmsision but same concepts. He did the same thing I did, clamping a two jaw puller in to the gap, otherwise the jaws pop off. The mainshaft is a more normal operation but the length of the shaft has to be managed. It takes some work. If you have friends that have pulled bearings or gears it might be worhtwhile to get some more ideas and tools on-hand. Notice the odd combination. Go to 4:00 if it doesn't start there.

-

4th gear doesn't use the countershaft, it's direct drive. That's a good clue. Sounds more like the countershaft bearing. Looks like you'll need to split the cases, so you might as well do the mainshaft/input shaft bearing also. It's not a super-finesse job. Just needs some ingenuity. It's fun. Part of Z ownership. Here's a good illustration of the parts you'll be looking at. I'm sure that there are "how-to" videos out there somewhere. You can get a factory service manual on the internet that shows how to take it apart. Good luck. https://www.zhome.com/ZCMnL/tech/240SX5spd/Transmission2.htm

-

"Grinding" is not very specific. Can you add details? Have you driven it? Is it the same in every gear? 71B's are known for destroying the adapter plate bearings. Did you find any metal on the drain plug magnet? If you've been driving it you might drain the fluid and see how it looks. Might also be worthwhile to lift the car and get underneath with the engine running to see if you can locate the noise. Replacing the main and countershaft bearings is not very difficult. You only have to split the cases and pull the bearings off of the ends of the shafts. The adapter plate bearings are more difficult.

-

Can you visually inspect a clutch/flywheel?

NewZed replied to nkopp's topic in S30 Series - 240z, 260z, 280z

Probably, but it must be an old one. https://www.centerforce.com/i-30500105-centerforce-i-clutch-pressure-plate-and-disc-set.html#!submodel%3DBASE - 2.8L - PRODUCTION FROM%3A 12%2F01%2F74 - PRODUCTION TO%3A 05%2F31%2F78||model%3D280Z||make%3DNISSAN||year%3D1978 -

Can you visually inspect a clutch/flywheel?

NewZed replied to nkopp's topic in S30 Series - 240z, 260z, 280z

That is not a Nissan pressure plate, as far as I can tell. I haven't seen those four square blocks on a pressure plate before. Might be some sort of "performance" clutch. So somebody has been in there and it's worth checking their work. The spring fingers seem to have some odd unbalanced marks on them too. How does the throwout bearing look? Don't forget to check the pilot bushing in the end of the cranksaft also. And, since the transmission is out, change the seal in the front cover, and the tailshaft housing. Check the speedometer gear seals. All common leak points. Might as well do the shifter bushings, when you reinstall it. They get brittle and crumble after many years. p.s. you should probably do the engine's rear main seal also. They tend to leak. Painful to get everything back together and find out you should have done it. . . -

Seems like a logical assumption. If it's a factory stock engine then a factory stock head gasket gets you back to factory stock specs. Trying to second-guess the engineers, who have all of the tools and money to test the variations, seems a bit foolish. Gasket restrictions are the same as port size restrictions as far as flow is concerned. You might have seen the comment from somebody in one of those old threads about the fact that after he got his cooling balanced across all six, using the head drilling/plumbing cooling mod, that instead of popping the seal on 5 or 6 from detonation, he popped all six at the same time. Something to consider. Probably better to spend time on the cooling system as a whole before fine-tuning the spread across the cylinders. Just an opinion.

-

Any L6 spray bar up to and including 1977 will fit. Looks like you could buy a junk cylinder head and save money if it comes with a spray bar. Don't forget the early 810's. Another option, if you can find all of the parts, would be a drilled camshaft. 1978 and later, including the ZX's. But you'd need the rocker arms and lash pads and it could still add up to a lot of money. Before you get too far you should probably inspect those dry cam lobes carefully for damage.

-

Look down the front cover area where the chain and sprocket are. The piece might have stuck on its way down. A magnet should be able to grab it if you can see it. I think that another way to fix that would be to braze it or use a high temperature solder. But an epoxy like SteelStick would probably work well too. You'll want to reinforce the joints that haven't failed yet also. It's a common problem with the early spray bars. Here's a whole long discussion about them on a different forum. https://www.classiczcars.com/forums/topic/41895-camshaft-oil-spray-bar-redesign-and-rebuild/#comment-377051

-

Lower Control Arm Bushing Housing Surface Damage?

NewZed replied to TalonA's topic in Brakes, Wheels, Suspension and Chassis

I don't think that it matters much. There's a small gap there anyway. I'd just file off any raised edges and put it back together. There will be plenty of good surface there. If you study how it works when everything is bolted together those two surfaces don't contact except under high loads. The locking pin in the casting and the inner sleeve of the bushings keeps everything centered. Under normal conditions the gap stays constant. p.s. for what it's worth, I have never heard of one those control arm (link) ears failing or the strut casting. The damage is certainly a stress riser but the parts are very robust. There are hundreds or thousands of damaged parts out there I'm sure. The stuck spindle pin problem has been happening for years. -

Lower Control Arm Bushing Housing Surface Damage?

NewZed replied to TalonA's topic in Brakes, Wheels, Suspension and Chassis

Pasco? Odds are pretty good that you can get them out without cutting. A lug nut has the same thread pattern. Stick one on, spin the rod around a bunch to break up the rust and crud, and beat it back and forth with a hammer. It might come out. Also, a long 5/8" bolt works well as a drift to punch it through. Don't forget to remove the locking pin. I found on mine that the spindle pin was actually stuck in the bushing sleeve, not so much the casting. Something to be aware of. The rubber would let it move but then pull it right back in. Heat the rubber up to degrade it if that's the case. No need to catch it on fire, just enough heat to degrade it. -

One fact that has been verified by many but might not be well-known is that the factory stock 280Z tank and fuel system suffers from fuel starvation on long left hand turns if the fuel level gets below about 1/3 full. You can find commentary about it in the various surge tank threads, I've had it happen to me a few times. It's a design flaw. It's pretty startling to have the engine cut out if you're accelerating through a wide long left on a busy street, on low fuel level. Something to consider for anyone rebuilding their fuel system or just looking to correct a real flaw in the system. A valid reason for a street car mod.

-

Are you racing or flexing? Ha ha....

-

Unnecessary opinion. Aren't you "flexing" with your performance knowledge? You can find threads out there about modifying tanks from other brands of car. You can also get replacement tanks, but they're expensive. It's one of those do-the-math situations. Good luck. https://s30.world/product/01-75-till-12-76-datsun-280z-fairlady-z-fuel-tank-vapor

-

The Airtex E8312 is a common aftermarket pump for the stock EFI system. It will put out 90 psi (unnecessary, too much) and about 30 gph (also more than needed). Don't get carried away on a bigger popular pump like the Walbro 255. 255 lph is 67 gph. Way too much flow and the pump will make a lot of noise trying to push through the small L28 fuel lines. There are several online calculators out there. https://www.google.com/search?q=horepower+fuel+pump+calculator You haven't described what you plan to do with the car. The race guys often use a swirl pot or surge tank.

-

Diff Mount to fit 350Z R200 Short Nose in 75 280Z?

NewZed replied to HusseinHolland's topic in Nissan V6 Forum

It's the propeller (driveshaft) and pinion shaft flange. But, also, on the side axles, you'll need adapters for the 350Z diff. Probably knew that. The axles won't swap. The R200's long noses are inherently noisy. Just rough and sloppy ring and pinion cuts. Many people hear gear noise when their diff mounts wear out, front and/or mustache bar. Clunking during shifting is also a sign of worn mounts. -

Diff Mount to fit 350Z R200 Short Nose in 75 280Z?

NewZed replied to HusseinHolland's topic in Nissan V6 Forum

The viscous diffs apparently have a very slight hesitation before they grab. It's a racing consideration. Don't forget that your 75 has a unique bolt pattern and size at the diff flange. In case you find a different long-nose R200 to swap in. Mfactory has what looks like the simplest long-nose R200 LSD solution. -

Diff Mount to fit 350Z R200 Short Nose in 75 280Z?

NewZed replied to HusseinHolland's topic in Nissan V6 Forum

The RTz mount is for the long-nose. Great design, works really well. But it's too far forward for the short nose. There are/were several short nose mount designs out there but none are really striking as far as functionality. The front of the short nose is just in a bad spot. Empty space up to the thin sheet metal above it. An example, looks like what ArizonaZcar used to offer. Maybe they still do. Uses the control arm tubes as mounting points - https://technotoytuning.com/nissan/240z/z-power-cradle-short-nose-r200r230-and-ford-88 Many of the short nose options have been discontinued. Many of the early designs had problems. Too much leverage. p.s. I'm on CZCC too. Zed Head. -

Maybe? https://www.google.com/search?q=fritz+cv+axles