NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Might have better luck on classiczcars.com. More traffic and there are some parts traders there. Good luck.

-

Bumping zboi's thread so he can continue his contributions to the community. Let's see an update.

-

Twin cam head for the L6 from Derek at Datsunworks

NewZed replied to Derek's topic in Nissan L6 Forum

The internet is a great place to learn. Learn first, then speak. https://www.investopedia.com/terms/e/economiesofscale.asp Where are those dyno numbers? If the engine still runs. -

I don't have Megasquirt but I know a little bit about EFI. Don't the MS data tables show injector open time? Duration? If open time isn't at 100% then it's not the injectors, it's MS not commanding them to stay open longer to provide more fuel. If they are at 100% then increasing fuel pressure should increase their flow rates. Sometimes on problems like yours it helps to break things down to the smallest elements. Analyze each step. What should happen versus what did happen.

-

Warning - poor R&D and customer service + credit card dispute

NewZed replied to idiot280's topic in Non Tech Board

RTPD = Read the post disappointed You should have created a fake name that at least leads to the mystery company. https://www.google.com/search?q=Flex+Engineered&rlz=1C1SQJL_enUS862US862&sourceid=chrome&ie=UTF-8 -

This part of the Megamanual might help. https://www.megamanual.com/begintuning.htm#spark https://www.megamanual.com/ms2/tune.htm

-

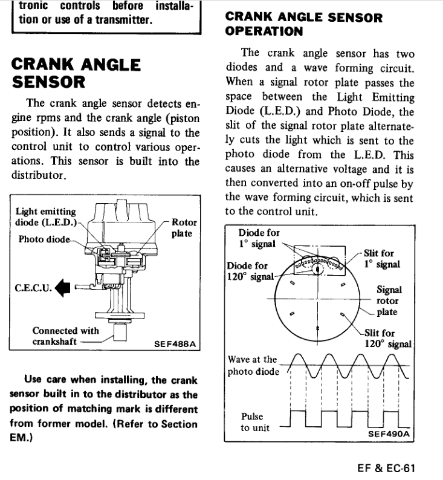

You have to look at your MAP tables. At high vacuum (low pressure) you can run more advance for a cleaner burn and better efficiency and better throttle response. At higher RPM under open throttle most people have found that about 34 degrees is where you get the most power. You can read a bunch in the L6 FAQ sub-forum about having timing set "all-in" at about 2500 RPM or various numbers around that. Meaning that it stops advancing and just hold at that advance number from there to the high limit. If I was starting with an MS tune I might first just mimic a stock engine's timing curves. Nissan provides them in the Engine Electrical chapters. You have to do some translation. And the charts are in distributor speed so that's where you have to do the doubling. From back in the days when they had distributor tuning machines. The early FSMs have an actual graph. Later ones have just a table and let you imagine the lines. Here is 72 and 78. 78 would be like your engine probably if it's a stock 290Z engine. They have different options for different markets and different transmissions. Generally, lower advance is for emissions states, like CA. Reduced timing is cleaner. notice that they give the starting point, zero degrees at XX RPM. So the first entry shows vacuum advance starting at 200 mm Hg, and increasing to 15 engine RPM at 350 mmHg. Centrifugal starts at at 1200 RPM and rises to 17 degress at 2500 RPM. It's like a mini general physics course. It can be confusing, especially since centrifugal is tied to crankshaft rotation but vacuum is just tied to air pressure in the manifold. Sometimes I still wonder if I'm thinking about it right. It's easier to grasp if you have a stock distributor on a running engine with a timing light to learn on. Good luck. 1978 EE chapter. 1972 EE chapter.

-

Not sure exactly where you're going or what the current problem is, but I think that the first comment above is incorrect, and the second one is correct. Also, you were talking about cam timing and ignition timing together at one point (the 4 degrees thing). They are completely separate as far as spark goes. You could move cam timng all over the place by switching holes on the sprocket and it would not affect when the spark occurs, relative to crankshaft position. Timing sensors are all measuring where the crankshaft is in its rotation. Cam timing is also relative to crankshaft position but adjusted separately from ignition timing. Just some hopefully helpful commentary.

-

I see what you mean about the pucks. Looks like a 240Z? Later ones were scalloped. If there's a gap and they're hard you can get a clunk when the diff and mustache bar twist under acceleration or deceleration. Or just from riding over bumpy roads. I haven't seen separate aftermarket parts, kind of surprising. Seems easy to reproduce. Here's some part numbers if you want to look around for NOS. Any year will work, the difference is the shape. 30 and 31 - https://www.carpartsmanual.com/datsun/Z-1969-1978/axle/rear-suspension The shifting clunk usually comes from the diff nose rising up then dropping back down, because of a loose front mount. The basic problem, that Nissan also was trying to solve, is that if things are too tight you get diff noise/whine transmitted in to the body. If they're too loose you get thumping and clunking. It's a balancing procedure. Probably best to ease your way to where you want to be.

-

The mustache bar bushings look okay. A new front diff mount will probably tighten things up a lot, worth doing. People have been very happy with the stock mount, if you can find it. The PU bushings were made for racing applications and pseudo-performance mods. I'd just do the front mount and see how things work. Not really sure what you mean by the "puck things". By the way, you can remove the mustache bar bushings by just heating the metal around the rubber while pulling or pressing on the bushing. The bond will loosen and they'll slide right put. The smokey bonfire approach is dramatic but unnecessary.

-

You're probably the first. I'd look at the short nose R200 and R230 mounting systems for ideas. It's hard to find a way to support the short nose diffs. Here are some threads. You can't get a reply if you post in them, becuase they are in the FAQ section, so make sure to post in this thread if you have questions. https://forums.hybridz.org/forum/83-drivetrain/

-

Disconnect the inlet or outlet hose to the pump. If fuel does not flow from the tank then the level is either not high enough or the inlet is clogged. You could also disconect the hose to or from the pump and lower the end toward the ground. Fuel should flow since the hole in to the tank is wide open. You could also dismount the pump and lower it to fill the pump with fuel. Once you get some liquid in to the pump it should pull from the tank.

-

Did you add the filter or did you replace a filter that was there before? You might need to loosen the hose at the outlet of the pump to let the pump gravity feed from the tank. Might help to fill the tank also, Maybe you're just low on fuel and the level is below the pump. The pump needs liquid in it to work. Any chance you got the hoses mixed up, or the wires to the pump? The pump will run backwards. Check the damper hoses also. You can prime the system by removing the small wire at the starter, the one that pulls off by hand, and turning the key to Start. The pump should run but the engine will not spin. Let the pump run for while by holding the key to Start. If there's air in the system you'll hear bubbles in the tank.

-

The site has definitley slowed down. It's not you. Did you see these? mobythevan is one of the original experts on MS. He's even referenced on the DIYAutotune web site. https://www.diyautotune.com/support/technical-articles/install

-

Actually, if you really wanted to do the math right you'd match the volume that is moved in the Chevy application. Controlled by the mechanical part of the system, the pedal. Probably easiest to just find out what's worked for other people. Good luck.

-

Looks like the aftermarket sells MC's between .71 and .75" for the Chevy's. The transmission doesn't matter, it's the match-up of slave and master that does. Browse Rockauto and you can find a few bores called out. There's two at 3/4". Probably a good idea to find the same brand master as the slave you're using and match that bore. https://www.rockauto.com/en/catalog/chevrolet,1996,camaro,5.7l+v8,1035931,transmission-manual,clutch+master+cylinder,1996 https://www.rockauto.com/en/moreinfo.php?pk=1277144&cc=1035931&pt=1996 https://www.rockauto.com/en/moreinfo.php?pk=1404771&cc=1035931&pt=1996 https://www.rockauto.com/en/moreinfo.php?pk=968991&cc=1035931&pt=1996&jsn=524

-

What struts to use in 2024?

NewZed replied to 74_5.0L_Z's topic in Brakes, Wheels, Suspension and Chassis

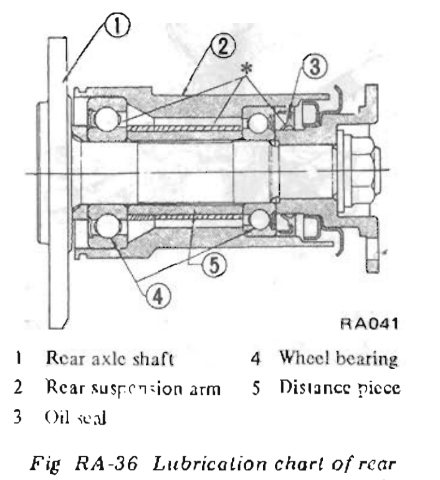

The axle fits in to the inner race of the bearing. The bearing outer race fits in to the casting. Might be a misunderstanding or just imprecise writing. An observation that might matter. Maybe you need a new axle. Good luck. -

Not an expert but it seems like you'll need to remove the head to find the cause. The "wet" test might not fix broken rings. As for head gasket, you could use the chemical test to check for combustion gases in the coolant if you wanted to be more sure. Turbo engines are susceptible to detonation when they're pushed. Detonation can cause drastic damage. Worrying about oil type now seems pointless. Good luck. https://www.oreillyauto.com/detail/c/evertough/rental-tools-evertough-combustion-leak-tester/ren1/67094

-

classiczcars.com is where the restorers hang out. I'd try there, you'll get more response. Hybridz is more about performance mods. https://www.classiczcars.com/gsc.tab=0

-

-

I would examine the movement of the breaker plate and the vacuum advance plate. Sounds like one or the other or both might be sticking. Changing your timing as the engine runs then sticking in the wrong spot. Based on what you are describing. Take your timing light with you and check the timing when you have problems. If you have to reset the timing to get the engine to start but get the same number with your timing light then something has moved within the distributor. I'd also watch a few videos about vacuum advance and mechanical advance. Good luck.

-

Also - check the grounds. The points and the Pertronix gorund through the distributor body. It needs to be grounded well to the engine block which needs to be grounded to the battery negative. And, the condenser on a points system can go bad, shorting the circuit, causing a no-spark condition. You can check that with a meter. And, also, if you have an electric fuel pump that could cause the low power problem if the carbs are running out of fuel. Many people convert to electric fuel pumps and there are many wys to go wrong there, beside the typical crusty old Z fuel tank. But if you get your ignition right you can forget about that and move on to fuel. Igniton timing is easy to set and measure and confirm.

-

Not really clear what you're saying here. But it looks like the closest to success of the two. What does "engine at TDC" mean? Do you mean igntion timng set to zero advance? As soon as you hit the starter the engine moves off of TDC. You need to define what is reproducible. You said that at some point it started and idled fine. Then apparently it was drivable until you adjusted timing to get more power and it would not start anymore. Also, apparently, you lost track of what the timing was becuase you ended up advancing and retarding it until it would start again. Why not just set it back to where it was when it started and idled? Way too much vaguness in your work. If you find a setting for the distributor that allows the engine to start and idle, put a mark on the adjustment plate so that you can go back to that exact spot. Years ago on my very first car I got stuck in a problem like yours where I tried to adjust timng like I always had and got it so messed up that I couldn't figure out which way to go. Since you're running carbs and the original distributor was electronic (260Z) I'd guess that the replacement distributor has messed up mechanical advance and/or the vacuum advance is not connected or it is connected and the breaker plate is sticking. You can check those with your timing light before you even try to drive the car. On the Pertronix - they are sensitive to leaving the key on. The key was probably left on and the module burned up. They actually have a warning in the instructions about that. Also, bypassing the ballast allows more current flow which will burn it up even faster. No offense but there's lots of wrongness here. I would try to get back to your first sentence (starts and idles fine), measure timing (get a real number not a "looks decent"), mark the distributor plate so you can get back to the setting that works, check the advance mechanisms by revving the engine with and without the vacuum advance hose connected, then if everything works correctly take it for a drive. http://www.pertronix.com.au/assets/pdf/Pertronix_Ignitor_1_Installation_Instructions.pdf "THE MODULE Always double-check, even triple-check that you have wired up the Ignitor correctly before starting your vehicle. RED wire to POSITIVE (+ve), BLACK wire to NEGATIVE (-ve). If the wires are reversed, the transistor will fail, the Ignitor will be inoperable, and the warranty will be void. An incompatible coil (refer "The Coil") may also cause the transistor to fail, by allowing too much current to pass to the unit. This situation also voids the warranty. Leaving the key in the "ON" position without having the engine running for extended periods can cause the coil to overheat, and 'cook' the Ignitor. Always ensure that the engine is running when the key is switched to "ON", otherwise use the "Accessories" position for use of other electrical components (e.g. Radio, CB, 12V source etc). A "key left on" situation is not covered by the warranty. Always be careful, as replacement modules will cost approximately 85% of a complete kit."

-

Car turns over but won't start

NewZed replied to KennethSrip's topic in S30 Series - 240z, 260z, 280z

Use a meter or test light and check for voltage at the injector connections with the key on. The ECU's on these cars are known to go bad. But that's just one possibility, don't start swapping parts. This guide will help for troubleshooting. It's from 1980 but it covers all years of EFI. https://www.classiczcars.com/files/file/32-efi-book-1980/ -

Car turns over but won't start

NewZed replied to KennethSrip's topic in S30 Series - 240z, 260z, 280z

1975 and 1976 have a fuel pump contact switch in the AFM controlled by the vane position. I'm guessing that it might be a 280Z or a 280ZX or a 300ZX since they all use AFM's. If it's a 280ZX there are other possible causes. If it's a 300ZX there are also other causes. Supply more facts and you'll get more specific suggestions. Good luck.