NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

That's a good find. Seems worth a look. The axle, at a stress riser, is where failure usually occurs at the hub. Their ad copy says "forged 5140" which seems to have some high stress uses, according to the internet. Cranks, for example. Not clear if they are cutting blanks from forged steel or forging the shape and machining though. Proper grammar would say "blanks forged from 5140...). Anyway. "Our Blank Output Flange is made from forged 5140 chromoly steel. " Number and diameter of splines and shaft won't tell you if it's a good fit for the axle though. You won't know until you try it. Spline shapes differ. You'll need to do some machining also, either a new distance spacer, or the flange, to fit the hub. Still interesting though. I'd spend $30-40 just to mess around with it.

-

Kind of looks like you didn't either. How would he know that Joe's out of stock if he hadn't contacted him? First post. Besides that it looks like he swapped his 240Z parts for 280Z and that's why needs 27 splines instead of 25. He confused the issue himself by leaving that out. Words....

-

Is this normal for a 350 sbc header to glow this red??

NewZed replied to Kado100's topic in Gen I & II Chevy V8 Tech Board

What brand of header is that? The hot spot is at the junction of the four pipes. Maybe it's just a poor design with a a flow restriction and thin metal. -

The pilot bushing, while small and simple (dull) and cheap, is very important. It supports the end of the input shaft. A loose pilot bushing can let the shaft rattle around. You might ask the shop. Any decent shop would know, it's a normal part of clutch replacement.

-

There's a nut on one of the shafts that's known to come loose. It affects shifting also though. Did you have the pilot bushing replaced when you had the TOB done? Also noticed in the other forum post that you said it makes the noise in the lower gears, but not 3rd and 4th. Might be meaningful. Good luck.

-

If you know some people with Z's or the same transmission you could take a ride and compare. I've had four in my car that all make the same noise, they all sound like they need work.. Did you find anything on the magnet when you drained the fluid?

-

Nobody said that Redline would help the noise BUSZED just made a point about thick oil damping the noise a little bit. You're not being very clear on what the noise IS,beyond a "rattle". A video might help your cause. To be more clear on this end, the bearing noise is more of a dull internal rumble than a rattle, that goes away when you press the clutch pedal. If you have a real, "bare metal shaking around" kind of noise, it could be something completely different. And Redline fluid isn't going to fix the bearing noise anyway. Edit - just saw your post on another forum where you call it a "chatter". Words are all we have out here, you have to pick the right ones and use them the right way, to create an image. Edit 2 - it also looks like you're getting your various suggestions confounded, like talking about Redline in this thread that never mentioned Redline. You're going to create a mass of confusion.

-

Fuel line modifications, among several seemingly small things. Read through the FAQ's on the L6 engine. Study the Z car terminology. For instance, we usually call the air flow meter an AFM, not a MAF. And an intercooler is a secondary item, not really necessary to "make the car running". http://forums.hybridz.org/forum/90-l-series/

-

How complex are the stock temp and oil pressure gauges?

NewZed replied to rundwark's topic in S30 Series - 240z, 260z, 280z

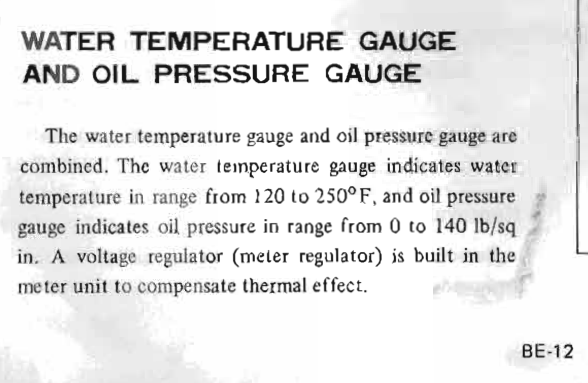

I think that the later service manuals might mention that if there's a problem it could be a bad voltage regulator. Think I've seen it in the 280Z FSM's. If both needles go wacky at the same time it's likely that, you'd think. Picture from 1973 FSM. -

Andreas is right, considering bore size. I was thinking of the classic N42, N47, F54, P90 head and gasket problem. L28 heads on L28 blocks. You have an L24/L26 head on an L28 block so an L24/L26 gasket might not seal the bore. Take measurements and consider coolant flow.

-

If there are no passages in the head the coolant has no where to go. And the head is probably more sensitive to coolant flow than the block. That would be my reasoning. Match the head, I'd say. Opinion.

-

This changes the situation. But, still, a condenser won't hurt. You might check your grounds and various connections too. Also consider just a low battery and/or weak alternator affecting the ignition system. The turn signals draw extra current and the Z alternators are known to be close to maxed-out at idle speed. Try revving the engine with the turn signals on and see if the dying needle fixes itself.

-

I've solved a twitchy tach needle on my 76 by adding a condenser to the negative side of the coil. It was a plain old alternator type, connected to the negative post. The early tachs are designed for the 6-volt system, with the coil and ballast resistor. The later electronic modules might just be too noisy for the early tachs. I'm not an electronics expert but I know that it worked for me, with a GM HEI module (the problem came back one day when the condenser/capacitor wire broke due to vibration), and it can't really hurt anything.

-

That resistance is probably fine. The E12-80 module has current control, I believe, it can handle it. The tach needle problem might just be a tach problem. Check the capacitor/condenser by the coil wiring. The tachs don't like electrical noise and the condenser is there to damp it. You haven't said what year car you're working with.

-

0.84 to 1.02 is the primary circuit resistance spec. on the stock 1979 coil. What's the resistance of the 8202? The odd behavior with the turn signals suggests other causes..

-

That's very common. It's one of the bearings in the transmission. Can't remember which one. Seems to be inherent to the design and the bearing that Nissan chose. Most make that noise. If it's really bad though it could be a sign of impending failure. If it just sounds like a rough rumbly bearing it's probably fine. If it's crunchy and poppy, maybe not.

-

There are threads about it. on the Hybridz site. Apparently, positioning #1 so the crank weights are out of the way is important.

-

Actually, that's 6 cm. 60 mm. You could adjust the rod out as far is it will go or even make a new one from an old bolt. People have done it before. Worth a shot. Or put a spacer between the rod end and the fork just for a short experiment. If it disengages you'll know there's hope.

-

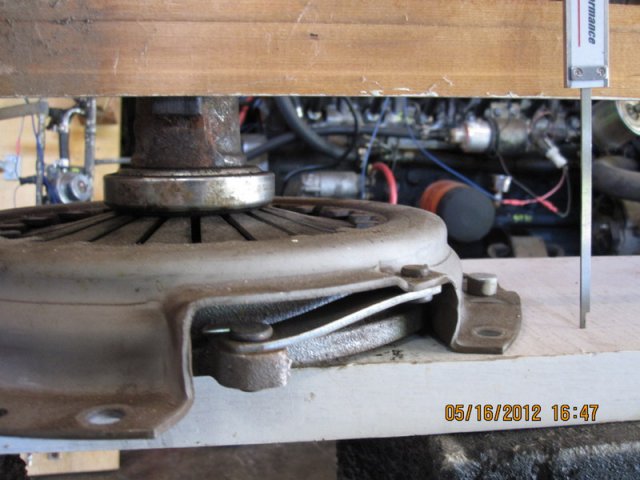

There is a variety of sleeves/collars out there, to match the various pressure plates. That's the key, the pressure plate and sleeve need to work together. The bearing fits in the sleeve and is replaceable. Many of us have found that a distance of about 92 mm from the surface of the flywheel to the surface the fork rides on, the two ears on the sleeve, when the parts are stacked, will always work. You'll find advice on mixing and matching by year of car and/or transmission but once the clutch has been replaced you're basically starting from scratch. Most new pressure plates are the short ones that require a long sleeve. Somebody probably kept the old 240Z sleeve with a new short pressure plate on yours. You could get the barn parts ready to swap on, then just do the sleeve if you find that it will work. Use the L28E fork also, with a newer type slave and rod. You still have the old adjustable type slave and fork. Attached a picture. Not exact but gives the concept.

-

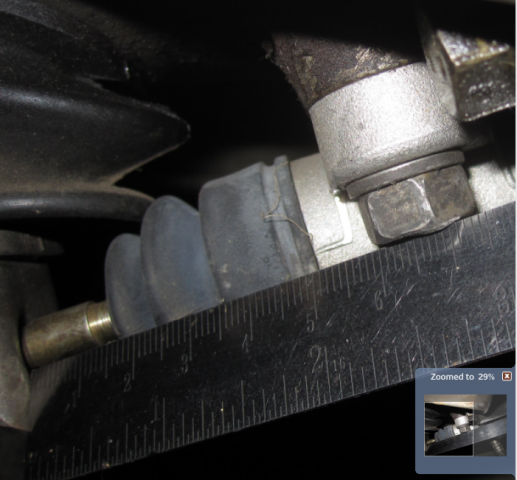

Here it is. This is with the clutch fork just about to move the pressure plate. The bolt head is the one on the slave cylinder.

-

You have a couple of things backward. What you describe isn't "slipping" it's lack of disengagement. The opposite of slipping. And you're moving the fork in the wrong direction in your video. But it still looks a lot like a short throwout bearing collar. The fork is very close to the end of travel before it would even start moving the pressure plate. From what I've seen the fork is about centered in the hole when it's sitting on the pressure plate fingers, on a proper system. Yours is way back, close to hitting the edge of the hole. I actually have a measurement somewhere, I'll see if I can dig it up. You probably need to take the transmission out and get a longer collar. MSA has them. Type "clutch collar" in the search box. http://www.thezstore.com/store/merchant.mvc?Screen=SRCHM

-

Isn't your real question "what does this line do?". You should determine that, then the answer will probably be obvious.

-

Transmission crossmember frame nut possibly crossthreaded?

NewZed replied to Stunt's topic in S30 Series - 240z, 260z, 280z

calz is making the point that the weight of the transmission is hanging on the nuts which are sitting on top of the metal tabs that are glued in place. Not a bad fix if you had welded instead of JB Welded. If the JB Weld fails the back of your engine will drop. -

You can just add a spacer (from a piece of pipe) to make up the distance on the rear strut. That's what Tokico does. Same strut on all four corners, two use a spacer. Seems like the distributor in this case just never got their database right and now they're screwed up forever. One of the downsides of the new technology age - mistakes tend to be permanent. There's a company out there advertising CV axles for 240Z's because somebody assumed and put it in to a database.

-

Fuel Pump Relay on Passenger side keeps clicking

NewZed replied to abbascamille's topic in Trouble Shooting / General Engine

Forgot to say, if you tried some things tell people what you tried. "Every possible idea" could mean one bad idea.