NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

It's on zcar.com, called "1976 280z wiring problems". Post #7.

-

I think that I just read some posts about a "key in ignition" buzzer,and the associated wiring at the ignition column. Somebody started one of those "where do these wires go" threads. It's recent, maybe this forum, maybe zcar.com. If that loose wire end was shorted, who knows.

-

You should make a sig with year of car and modifications so people know what wiring system you're working with. Too many pages to try to figure it out. Really though you should just sit down with a wiring diagram and a meter and verify continuity to the positive cable on things that get power and continuity to the negative cable on things that get grounded. You're just shooting in the dark and blowing holes in things you can't see at this point. Your new motor deserves the time.

-

Stock valve seals are too tall. Valve springs might bind. There's a bunch of practical stuff already written on the forum somewhere. are

-

A similar path has already been blazed. A short summary at #20 here - http://forums.hybridz.org/topic/121328-snapping-stub-axles-now-what/ Some good pictures at #18 here - http://forums.hybridz.org/topic/117652-finally-blew-an-axle/ Oops. wrong side for RebekahsZ. Still, similar topic.

-

It made 17 volts before he swapped the alternator. Now it makes 16+.

-

I don't think that there's less material at the typical break point, is there? I thought that they usually broke at the spot where the splines end. That would be the same size for both Nissan and these. Many shafts are designed to be thinner in the middle, with a thicker spline diameter, to spread the load across more material. But many are also designed for manufacturing efficiency and low cost, like Nissan's.

-

Stronger motor mounts

NewZed replied to jessejames's topic in Brakes, Wheels, Suspension and Chassis

That's a nice design those Silverproject mounts use. Simple but effective. Don't know why they call them "solid", it gives the wrong impression. -

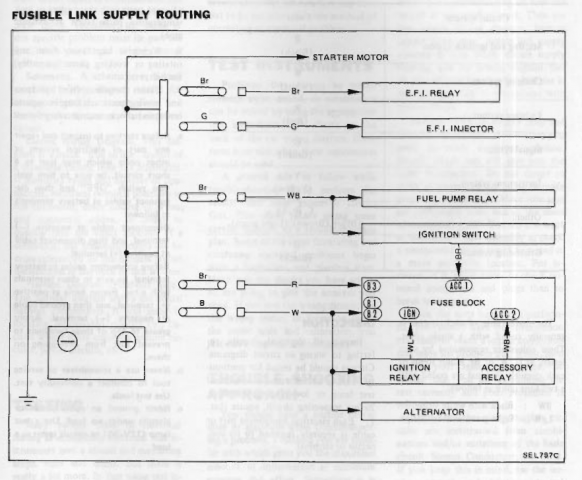

Voltage "popped up" while the engine is running, right? You are using a good meter? Sounds like your voltage regulator Sense wire is not sensing. You should focus on the "burning up" fusible link. Fusible links are there for when things aren't right. So, obviously, something is shorted, probably, on that circuit. Check the wiring at the starter for starters. And use your meter to be sure things aren't shorted, before connecting the battery.

-

I was just trying to make the point that fuses, fusible links, starters, alternators, etc. are pretty easy. Complete wiring harness swaps are hard. You have to break them down into components and sub-harnesses. Beside that your question is really "where is the short that's causing my fusible links to melt". That's your #1 problem. Not 12 volts to block, or why does'y my car run? Just being blunt to let you know it's not going to be easy. Good luck. Take good measurements, measure continuity back to the positive and negative cables before connecting the battery to be sure things are right.

-

Fuel pump troubles. Car won't keep running on idle.

NewZed replied to StanTheMan's topic in Fuel Delivery

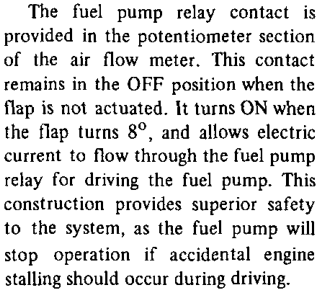

Not a bad guess. Here's what they used in 1975-77. They changed it in 1978. Note that the PCV system pulls air through the crankcase. So the crankcase needs to be sealed otherwise less air passes through the AFM causing less flap movement. Emissions chapter. -

The bumble zee guide is for people swapping only the EFI harness, Replacing the entire car's harness is a much bigger project. Use the 1983 FSM Electrical chapters if you want to see the diagram of how Nissan did it. A diagram is better than pictures. Seems like you've overshot your abilities and will have to get them caught up to what you're trying to do. Worrying about "engine block getting 12 volts" shows that you're quite a way from where you should be. Study up on basic automotive electrical concepts, like how and when current flows, what the voltage readings mean, what the fusible links are for, etc. No offense intended. You should be comfortable with this anyway after you get beyond this one simple problem. There will be more, that are more complex.

-

Disconnecting the alternator was a good idea. Isolate the various components. Don't overlook that the electrical system is centered at the starter lug mainly for convenience. The white wire from the alternator that runs through the fusible links could be connected directly to the battery positive, for example. You might have a shorted starter. Realize that the end of that white wire is branched to several subsystems on the way to the end of the battery positive cable at the starter. As you isolate each component, like the starter and/or alternator, and study the fusible link wiring, you'll probably figure out where the short has to be. Consider completely disconnecting your transplanted EFI system, to be sure that the basic wiring is correct. Then add the ZX EFI sub-harness. You might have just switched a wire on the 76 harness by accident. Confirm that the original parts are still correct.

-

Fusible link covers Trouble light covers Vent louvers for 77 and 78 vented hoods

-

What kind of cores?

-

Could also be that you connected your battery backward the first time. It's pretty common. Once the fusible links melt they don't conduct anymore. And you might have melted your ground circuits the first time. You can use your meter to confirm that things are right before replacing them. Check that you have continuity where it should be before connecting any power. You shouldn't use smoke as a troubleshooting tool.

-

The fusible links would normally just melt, with a touch of smoke, maybe, if there was a short. So the sparking doesn't really make sense. The 12 volt reading is correct, as you described it, to the block. What you mean by "chassis" is unclear. In short, it's not clear what the problem is, besides some sparking. Not sure what you mean by "it".

-

yes its easy just s and l and the solenoid wire and the charge wire and the battery cables. you can ewven use a screwdriver if you want to avoid the solenoid wire

-

The basic problem is that the studs are commonly NLA. You have to find old stock, apparently. You can start at #175 here - http://forums.hybridz.org/topic/78123-subaru-wrx-sti-r180-side-axles/page-9 and again at #237 http://forums.hybridz.org/topic/78123-subaru-wrx-sti-r180-side-axles/page-12

-

Never heard of a "kit" for that. There's not much to replace. If the boots are okay, all you really need is a new clamp to hold them on. A CV boot clamp would work. All you'll really be doing is replacing old grease.

-

You can search around John Coffey's threads on the axles for the Subaru diff and you'll find some part numbers, I think.

-

If you decide to try the machining to make it work, you might look in to another heat treatment to get the desired physical properties, if you can't determine what you have now. Although I think heat treatment can change your dimensions.

-

It's the shape of the teeth and the grooves that will get you. I picked up a J30 diff because it has a 28 spline axle (just to mess around with, I know that the VLSD has la longer axle) and found that the stock Z axles were sloppy in the J30 and the stock J30 axles were very tight in their original home. Can't remember if I tried the J30 axle in the Z R200 or not. That's why I bring it up though,. It's more than number and diameter.

-

Sorry Joe. I knew there was another supplier out there. This is the one, right? https://whiteheadperformance.com/product/whp-billet-cv-300zx-z31-turbo-axle-companion-flange-adapters-27-spline-datsun-240z-260z-280z/

-

Have you stuck an axle through there yet?