NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

By parallel, I mean side-to side also, not just up and down. And don't forget your half-shaft u-joints, if you're using those. Or a bad CV joint. And the u-joints on each end of the driveshaft need to be in phase. In case you made it yourself. Might have missed it. Fun video -

-

There's actually quite a bit of old stuff on the forum about how to set the transmission/motor and differential angles. Those are what matter. Their axes have to be parallel. The driveshaft angle is a side-effect. Use Google ans search "site:hybridz.org driveshaft angle", or "driveshaft vibration" and you might find something. Add "laser" and "alignment" and you'll probably find jmortensen's thread on a laser alignment method.

-

Pretty sure he already has the recommended diff. RebekahZ's diff is in the paragraph in all of his posts describing his car's mods. And most 280Z's came with a 3.54 R200. He just needs an LSD to go with it.

-

Beautification.

-

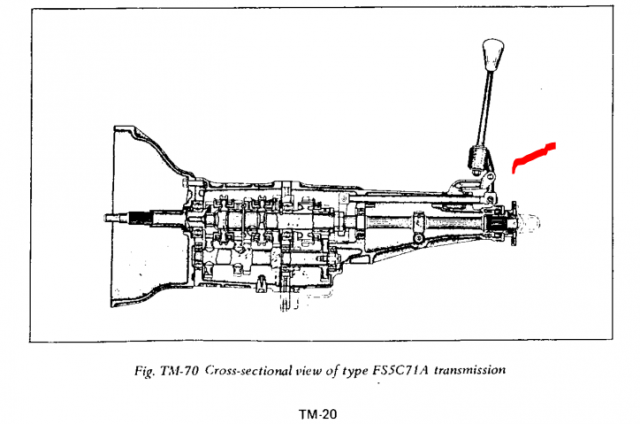

I think that the Service instructions you want are here, in Part 1 - http://www.classiczcars.com/files/file/20-1970-71-240z-factory-service-manuals/ Pretty easy to open for inspection using normal tools. Some special tools required to disassemble it. I took another look at your picture and don't think that that is an early 240Z 5 speed. Might be a later model competition 5 speed. Can't remember the details of how to tell (there are threads on this forum - search competition 5 speed) but your shifter mechanism is the newer "B" style, not "A". So any of the other 1977 to 1983 5 speed instructions will tell you how to open it up. I'd go with 1983. Your rear case looks like a later ZX style. But your output flange is odd. Might be a hybrid transmission. Might be a truck transmission. Doesn't look a like a 240Z transmission. And it looks like the cases have been split recently, they're clean and different color. http://www.classiczcars.com/files/category/9-factory-service-manuals/

-

I think that he already has a car and he's just going to buy one of these two for the engine or the turbo parts alone. The car body and extra parts will be sold. Look at the other parts like the transmissions and differentials. Determine the value of the other parts, and do some math. Wrecking yards will always give $100 or so just for the value of the metal. If the engine in the bad car runs and can be evaluated I'd probably go for it, especially if you're going to use the ZX ECCS engine management. You'll have everything you need, working. You'll have a running turbo engine for the the car you have, plus a running spare NA engine for when you blow up the turbo engine. The locked up engine car could leave you with a pile of parts and still no turbo engine. Who knows what else is broken in the locked up engine?

-

A late 80's Pathfinder/Maxima CAS and distributor can be made to work, kind of like this Jeep sensor swap, but with a little more work on the L6 mounting stand, the hole is 1mm too small, and the stand is 5mm too tall. Then you could use DIYAutotune's replacement trigger wheels. https://www.diyautotune.com/product/54-mm-optical-trigger-wheel-for-nissan-l28et-or-vg30e/

-

This guy has moved on to bigger stuff, like complete cylinder heads, but he might still have some of these. http://forums.hybridz.org/topic/121177-just-finished-a-new-run-of-edis-mounting-kits/

-

I have a Pathfinder CAS apart, slotted disk removed, trying to figure out why it doesn't seem to work work and don't see any light when I apply 12 volts across the red and black wires (cgsheen's test method). Has anybody actually seen the LED light up with a CAS apart? Seem like it would be a simple first test method, rather than last after dinking around test that I just did. I think mine's dead, but verification is always good.

-

Not necessarily. Consider the working temperature of the transmission,probably at least engine temperature. The aluminum will expand quite a bit. If it drops in with a little bit of heat, it will be a "loose" fit during usage.

-

Some reading - http://www.nskamericas.com/cps/rde/dtr/na_en/na_literature_bearing/07_TechTalk__Getting_a_good_fit.pdf http://www.ntnamericas.com/en/product-support-and-training/shaft-and-housing-fits

-

You said said disssembly but it looks like you mean assembly. "we ended witha bearing stuck in the bellhousing while disassembling it. " Sounds like you used a .015 mm interference fit and now you cant' get the bearing in. .015 mm on a 62 mm bearing. Doesn't seem like it should be a problem. I know what I'd do but the pros would have a more valuable opinion. Good luck.

-

Can't tell if you're about to open the hole or you've already done it. You could measure the existing hole to see what Nissan did. I think that Nissan set their specs for a hot transmission case. For example, the countershaft bearing preload shim.

-

Humor. If we took a poll I bet that 240's and 280's would be more popular than 260's. It's just one of those things that is.

-

Low number 240Z's are a hot item because they are the first Z cars. You have a low number 260Z. Not really the same. For whatever reason, the 4 and the 8 just look right , and the 6 doesn't do it for many people. Any good rust-free early body style is probably worth something to somebody though. You might put it on the market before you part it out. Make some cash instead.

-

Front is where the headlights go. Just keeps things so much simpler. Wrong for the ZX >>>> (The rubber bushing needs to go on the side with the nut). Edited. The mechanism I was talking about is the one that breaks the rod tip off. The hard PU puts a side load on it as the rod moves up and down. I broke one on my car. It took a couple of months of groaning over the driveway entrances. You could hear a lot of load on them. Rubber on the nut side is quiet now. Always an interesting topic.

-

For the 280Z's, with the rod in compression under forward braking, it's polyurethane on the back of the rods that causes the problems, especially if the worn out rubber inner control arm bushings are kept. Puts a bending load on the tip. Rubber on the back and PU up front is the recommended way. But you have a 280ZX, with the rod under tension when forward braking. I haven't seen much on those rods breaking. It's a different design than the 280Z.

-

Probably should have went .zip. .rar is uncommon.

-

Pertronix Ignitor II / Flamethrower II

NewZed replied to P-Funk's topic in S30 Series - 240z, 260z, 280z

Get the part number here - https://www.summitracing.com/search/product-line/pertronix-ignitor-ii-solid-state-ignition-systems/make/nissan/engine-size/2-4l-2393cc/engine-family/nissan-inline-6-cylinder Then get the instruction sheet here - http://www.pertronix.com/support/instructions/ The coil specs and other details are there. You might examine your distributor closely to see if it's worth keeping before you spend the money on a Pertronix Ignitor. Check the advance mechanisms, bushings, etc. If you need to replace the distributor there are other ways to go electronic. -

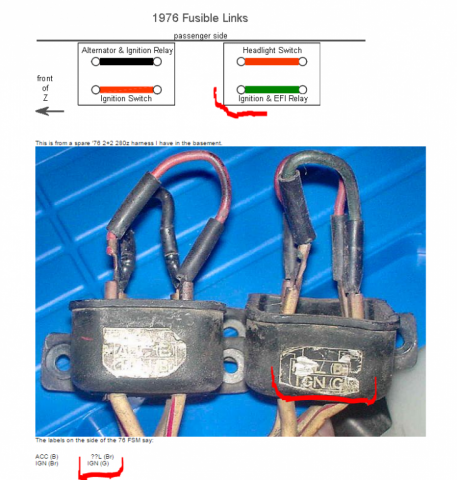

The guys that put that site together did great work and provided a very valuable service for all of us. But they made a few mistakes. Probably thinking about the link colors when they were putting their labels on (EFI and IGN are both Green). There are are actually clues if you look at everything in the picture. Nissan built the cars. Use their diagrams to be sure.

-

There's an ignition link. And there's an EFI link. There is no "ignition EFI" link. The free downloads on nicoclub have diagrams.

-

You meant "incorrectly". The EFI link isn't even in that fusible link block you're replacing. The red link on the atlanticz page is rated too high for the one it's replacing. The gauges are shown in the FSM. Brown is lower gauge (lower current capability) than both green and black.

-

The cam towers can be manipulated to get the cam to rotate freely. It never seems to be a problem. Not sure what you mean about the pitting. There's no pictures. Sanding doesn't sound like a good idea though. It's not the pits, it's the bumps, that would be more of a problem. And sand. What's the letter stamped on the end of the cam shaft? They might be the same profile.