NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Testing - https://www.summitracing.com/ Let's see what happens... You're right. Image copied below. Trying Amazon now. https://www.amazon.com/ Amazon works fine. Summit must have a problem. How about a hybridz.org link to be sure. Do loop... http://forums.hybridz.org/topic/126603-site-redirecting-links-to-viglink/?do=findComment&comment=1183339

-

You should have that head checked out, at least get the chamber volumes measured. It might have had port and/or combustion chamber work done, along with surface milling. It's probably not a stock head anymore so the CR calculators won't work. And choosing a proper cam will be worth much more than a bump in CR.

-

That wasn't my point. I was just offering a clue. Nissan did make some one-off parts, apparently. The J30 short nose diff with the unique spline count for example. Wouldn't be a surprise if they had ABS as an option on a 300ZX. There are some things that didn't make it the the service manuals. But Infiniti M30 diff seems like a reasonable guess. Seems like kind of a distraction though. The real story is that your buddy didn't get what he thought he was getting. Hope he didn't pay too much.

-

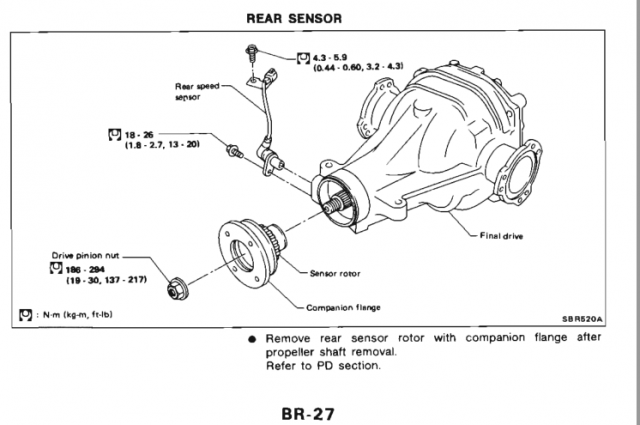

Maybe the early primitive anti-lock brake systems just controlled front versus back but most control wheels individually. You can't do that from the pinion shaft. And the pinion flange is at the same speed as the speedo drive, so no differentiation. And the ZX's went to electronic speed sensors pretty quickly so that signal could be used. The short nose diff ABS had toothed wheels inboard of the axle flange. Thar sensor is most likely a cruise control sensor, I'd think. Just puzzle-solving. Edit - wait. the !989 240SX appears to have a sensor like that, that measures pinion shaft speed. Guess they wanted to keep things separate from the speedo signal. But it's a short-nose. So close.

-

You're right . Sorry Joe, I got my emphasis wrong.

-

You're talking to Joe right? The topic was cruising until he came in with comments about short runs, and other people commented "stop thinking and just buy the parts from Joe". We're just trying to figure out how to get what we want without waiting for a group buy. These types of threads are where the ideas for the products Joe is now making came from. The free market is about competition. My comments should be helpful to Joe, and Whitehead, if they take the time to think about them. New ways to get there will be devised if the other paths are too time-consuming or expensive. Pretty simple concept.

-

Starting fluid. Pop off a small vacuum line and squirt it directly in to the intake manifold. At least you'll know if it will run once started.

- 11 replies

-

- Compression

- oil pan heater

-

(and 1 more)

Tagged with:

-

Could the sensor be an aftermarket cruise control item? Red herringish. My "28" might be off. With 240Z, 280Z and 280ZX hub axles and flanges, and the two differential spline counts I get them mixed up. Ishould have left it at "my 280Z open diff axles fit the J30 VLSD diff". The 3.9 ratio and long nose implies early 300ZX doesn't it? That's why I was curious about if it's really a VLSD. You can tell by looking in the hole and seeing where the internal splines are. You can see where the two sides of the VLSD clutch split on the long shaft.

-

Stronger motor mounts

NewZed replied to jessejames's topic in Brakes, Wheels, Suspension and Chassis

There you go. Spending Porsche money on your Z. -

Stronger motor mounts

NewZed replied to jessejames's topic in Brakes, Wheels, Suspension and Chassis

Nahh. Nothing wrong with saving some money. You're just used to living in Canada maybe. $165 is still a lot of money down here, Unless you're in the Porsche game. -

It's not the ordering, it's the waiting. There's a basic business problem here. If all of the parts come from the same supplier but people aren't ordering because there's essentially a group buy requirement, then keeping the customers separated kills the demand. Makes no sense. One guy orders from Joe and he says "you'll have to wait until someone else orders a pair", another guy orders from Whitehead and he says the same thing. Both guys cancel or don't order yet the numbers are there. How is that going to work? Especially today, when we're all trained to expect our stuff tomorrow, soon delivered by drone, to our doorstep.

-

Just trying to keep my knowledge fresh, not arguing. But I have a J30 short nose VLSD with 28 splines. The older shafts slide in and fit but are a bit loose. And one is too short to engage the viscous "clutch" so it's essentially an open without the long axles, of course. What about the short nose/long nose question? Are there other long nose VLSD's besides the 1988 Shiro?

-

What year car? Is it fuel-injected or carb'ed? Is it factory stock or modified? Will it start with starting fluid?

- 11 replies

-

- Compression

- oil pan heater

-

(and 1 more)

Tagged with:

-

By "don't fit" do you mean the spline count is different? Or the shafts are too short? Why do you think it's a VLSD? I'm not sure but I think that the Shiro was the only long-nose VLSD, unless Nissan used a long-nose VLSD with different axles on other models. They went to shortnose in 1990 and VLSD for the 300ZX's, from what I can figure. So long-nose would be 1989 or earlier. I think.

-

Stronger motor mounts

NewZed replied to jessejames's topic in Brakes, Wheels, Suspension and Chassis

Don't forget adhesion. The picture that the Energy Suspension link shows is just an old rubber mount filled with urethane to make it more solid. Getting good adhesion to the metal plates the factory mount uses will probably be difficult. Doesn't matter how strong or stiff it is if it peels off of the steel. Could be one reason that ES has that interlocking design. It puts a compressive load on the material and takes much of the tensile load off of the metal/PU interface. Just saying, it's not as simple as it seems and mistakes can cost. -

Fuel pump troubles. Car won't keep running on idle.

NewZed replied to StanTheMan's topic in Fuel Delivery

Can you make a video? I'd like to see it, I'd laugh I'm sure. The gaskets are just compressed rubber that eventually hardens up and shrinks, or the previous guy tried to reuse old shrunken gaskets. Pretty simple repair. http://www.thezstore.com/page/TZS/PROD/11-3402 The 3-4 second running then dying is still probably your AFM switch. -

You're missing or ignoring the point. Buy a car somebody else built. Let someone else drive it and win races. Buy a video game with cars in it. People are just discussing possibilities and learning a little on the side. Beside that MMM products almost disappeared when MMM went out of business, and Joe needs an order of four to make a new run. What does a person do in the meantime? what if Joe goes out of business? Joe, you should put the need for four orders on your web site. And there's competition now that doesn't seem to need four. Just saying, communication is important.

-

It was implied in another thread that you were out of stock. So people started looking for alternatives. http://forums.hybridz.org/topic/126482-27-spline-cv-hub-adaptors/?do=findComment&comment=1182246

-

If I was jumping in to try this at this point, I might just go to the wrecking yard and pull the flange from the appropriate Toyota diff. Probably charge you about the same. If they're scarce, do the development work on the aftermarket parts for $30 each, then lock it in with the factory part. I like OE parts.

-

Stronger motor mounts

NewZed replied to jessejames's topic in Brakes, Wheels, Suspension and Chassis

Polyurethane is not inherently stronger than rubber. It's easier to work with, generally, so the aftermarket guys can get crazy with it. -

-

These are almost certainly Asia knockoffs, copied from a factory Toyota part. $30.45! Communicating with the supplier will probably be very difficult. Worth a shot, but odds aren't good, I'd think. With that in mind, consider also that they might not really be 5140, let alone forged. It looks like a fun exercise and might lead to something good, but I wouldn't put too much faith in them when they're done, without some testing. One of those things that's neat if it works but has substantial risk associated. A follow-up might be to find a supplier of the same part, but from a verifiable manufacturer. Probably cost more money but the leg work's been done on the cheap stuff.

-

You definitely need a 280Z R200 mustache bar if you had an R180 in there. Especially if you have an early 240Z with the diff offset forward Burleigh sells a curved "dog bone" (part #25) to clear the fins for the CLSD diffs. You shouldn't need to change #26. You might be getting misdirected. Swapping an R200 in to a 240Z is pretty well figured out, and the fins just add an extra problem. http://forums.hybridz.org/topic/97134-steel-brace-for-clsd-r200-finned-cover-use-in-s30-zcar/page-3?hl=burleigh&do=findComment&comment=914568

-

Sure you didn't mean #25 instead of 26? And the 240Z and 280Z crossmembers look the same in the FSM drawings. All bolt holes are on the same line. If you're trying to use the R180 rubber with an R200 that might be your issue. I think that the early rubber, or the R180 rubber, might be different. Can't remember which, on the R200 swaps.

-

It's possible to remove and install completely assembled. You just need to have the right tools and room to use them. A leveler on your hoisting rig, for example. A way to lift the tail of the transmission when it's under the car. The engine and trans together is pretty heavy. The preferred way would be the one that you're comfortable with, I'd say.