NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Need a mechanic in Michigan area please.

NewZed replied to Notamechanicsobepatient's topic in Nissan L6 Forum

The engine code is stamped on the side of the block, above the #5 and 6 cylinders. It will say L28 if it's an L28. How fast is fast? The L28 moves the cars pretty well. It will be difficult to find a mechanic who can work on the old Datsun engines. Good luck. Put "Michigan" in the title of your post to catch some eyes. -

Can't you look a little bit longer, and further afield? $1200 doesn't seem like a great deal, the 260's are the odd ball Z's. Not too exciting. You could probably find a 280Z that runs, out there somewhere, for $1200. The clutch system is hydraulic and there's no way it's going to work. After 10 years,outside, most Z's will have the rear brakes locked. A couple of cylinders will have valves open, and outside, there will be some small surface rust, probably stopping the engine from spinning. Best to squirt a bunch of oil in the plug holes before trying, just to reduce damage from scraping over rust. Condensation cycles over many years can actually fill a crankcase with water. Best check oil level first. If it's high, there's probably water at the bottom, lifting the oil. Under the battery, and the floors are the most common rust spots. Check the gray car's rear suspension. I'd say that one's definitely not going to roll.

-

Looks like fun. I'd put something about Motronic or BMW ECU in your title. Otherwise it looks like a thread about a boring old Z or ZX ECU. Beside that, I think that BMW calls theirs ECM's.

-

Won't start after fuel rail upgrade

NewZed replied to Turbo_the_world's topic in Trouble Shooting / General Engine

Good news. Now, back to those vacuum leaks... Those two books are still worth looking through, The FSM and the Injection Guide. Nissan did a great job of describing how everything on their cars works. -

Standard. British Standard. Click the underlined blue letters.

-

Won't start after fuel rail upgrade

NewZed replied to Turbo_the_world's topic in Trouble Shooting / General Engine

Believe what you see. Figure out how it happened later. Did you pull the plug wires when you were doing the fuel rail work? Or remove the distributor? Many of these engines have been put together wrong and had their wires moved to "fix" the error. You probably put the wires back the way they're supposed to be when the rest of the engine is right. Put the timing mark on zero, with the cam lobes for #1 up, and see where the distributor rotor is pointing. It should be pointing just left of straight ahead (there's pictures out on the internet somewhere). Or do that and post a picture. Or remove the distributor and see where the drive tang is pointed. Equal voltage on both coil posts is normal. It doesn't change until the distributor is spinning. Here's some good information. You don't need all of it. http://atlanticz.ca/zclub/techtips/distributor/index.html -

It's probably BSPT, British Standard Pipe Thread. That's what Nissan used on many of the engine port threads, the oil pressure sender, for example. http://www.ralstoninst.com/news/story/the-difference-between-npt-bspp-and-bspt-seals/

-

I quoted this post just to illustrate. There are two sides to building pressure - what the pump puts out and what the regulator holds back. You said that you've replace many things but it's not clear where those things are or what they're rated to do . For example, your 10 micron filter might be designed for a low rate carb pump. ?? Who knows. But, what you want to do is break the whole system in to parts until you narrow things down to the source of the problem. You've spent enough time and money to justify some simple experiments, like maybe running a line with a gauge and your FPR directly back in to the tank without the filter. That will isolate the most basic elements, the pump and the FPR. If everything is fine, pressure jumps and holds to where it should be, then insert the filter and see what happens. Or just take a leap and remove that filter for a test. A few particles for a short while won't hurt anything. This is basically what rsicard was saying. Isolate the components. Your injectors can't lower pressure unless they dump a ton of fuel, so they are not likely the cause. The chattering might actually be some sort of power loss. Maybe that's the problem. Regardless, you have to isolate the pieces. The fact that you have to wait for pressure to rise indicates a restriction. If I had to guess, I'd say it's your 10 micron filter. Why not just run the big ugly paper filled can? It's big to allow high flow. And the injectors have their own screens.

- 6 replies

-

- fuel

- electrical

-

(and 1 more)

Tagged with:

-

Tach Not Reading Below ~1200 rpms

NewZed replied to 78-280Z's topic in S30 Series - 240z, 260z, 280z

Actually, it might be voltage quality, not quantity, with the alternator clue. An alternator is an inherently noisy electrical source. Condensers and resistors can both suppress noise. Not an electronics expert. -

Won't start after fuel rail upgrade

NewZed replied to Turbo_the_world's topic in Trouble Shooting / General Engine

76 has electronic ignition. Engine Electrical. You didn't say how the spark looked. The fact that the injectors sprayed while cranking indicates that the coil was discharging. That's what the ECU uses to know when to open the injectors. Go to the basics of what's supposed to happen. If the cylinders suck in some starting fluid and there's a spark you should at least get a pop. Something's missing. The details are important. You didn't describe the spark, and you haven't said how you sprayed the fluid, just "in the manifold". You might be spraying in to an electrical plug. Who knows. Thinking about replacing the coil without testing it is a bad sign. The beauty of these cars is how much testing information is on the internet, free to anyone that want's to use it. You could have had the whole system tested by now, with a meter and one of those books. Just saying... -

Won't start after fuel rail upgrade

NewZed replied to Turbo_the_world's topic in Trouble Shooting / General Engine

How do you know the injectors were firing? That's the part you just worked on so the most suspect. If they were squirting and you have dry plugs, there's a logic issue. You can see the disconnect there. Is the spark strong and bluish or weak and orangish? Sometimes you can get spark in open air but none under cylinder pressure. The old 280Z ignition modules are failing at a pretty regular rate. If random actions fail you could start at the basic troubleshooting steps described in the FSM and the Fuel Injection Guide. The 980 Guide covers all years up to 1980. http://www.xenonzcar.com/s130/other.php -

Won't start after fuel rail upgrade

NewZed replied to Turbo_the_world's topic in Trouble Shooting / General Engine

Well, that's a bummer. Fuel pressure should be 36 psi but you should still get a pop or two. It should start. Are the spark plugs wet or dry after a no-start attempt? Did you try the starting fluid directly in to the manifold? Pop the little hose that supplies the AC control bottle and squirt some in there. The hose next to the booster hose. -

Won't start after fuel rail upgrade

NewZed replied to Turbo_the_world's topic in Trouble Shooting / General Engine

I'm going to predict that your next problem will be that it starts but idle speed is off. Either too high or too low. It might also start and idle cold but die when warmed up. Just a guess. Enjoy. -

Won't start after fuel rail upgrade

NewZed replied to Turbo_the_world's topic in Trouble Shooting / General Engine

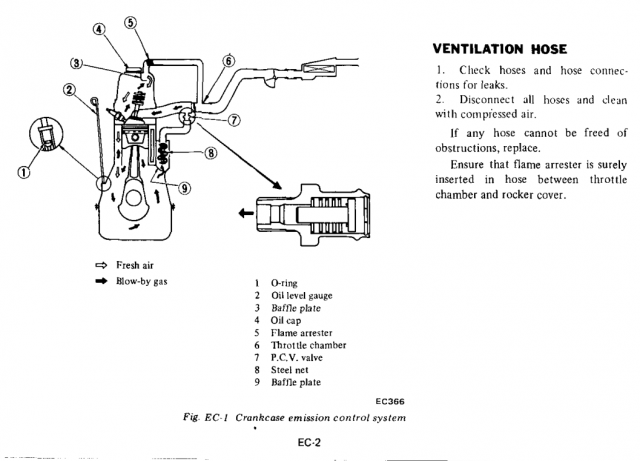

Unintended consequences. You can either put the system back together or block it completely. It actually keeps your oil cleaner, and your engine bay. Removing parts that aren't understood is a common problem source. -

280z Harness Help (Plug/Wire Identification)

NewZed replied to wam8827's topic in 6 Cylinder Z Forums

Don't get angry. Just having fun watching. -

Won't start after fuel rail upgrade

NewZed replied to Turbo_the_world's topic in Trouble Shooting / General Engine

And don't get mad. What you're doing is just amusing to everyone out here that's worked on the EFI system. -

280z Harness Help (Plug/Wire Identification)

NewZed replied to wam8827's topic in 6 Cylinder Z Forums

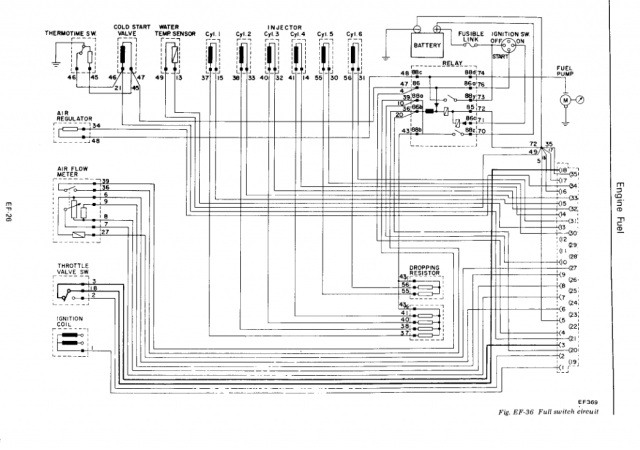

Open that FSM chapter. It's not as hard as it looks, it really isn't. You're just hacking around until you do. Y'all people are every where. Hack, hack, hacking away - http://forums.hybridz.org/topic/125532-wont-start-after-fuel-rail-upgrade/?do=findComment&comment=1173508 http://www.nicoclub.com/FSM/280z/ -

Won't start after fuel rail upgrade

NewZed replied to Turbo_the_world's topic in Trouble Shooting / General Engine

You thought half-right. http://www.nicoclub.com/FSM/280z/ -

Won't start after fuel rail upgrade

NewZed replied to Turbo_the_world's topic in Trouble Shooting / General Engine

I just took a second look at your picture and see that the PCV hoses are gone. There's your problem. Put the PCV system back together. Google "280Z PCV vacuum leak". Read the Emissions chapter. It's all there. -

Won't start after fuel rail upgrade

NewZed replied to Turbo_the_world's topic in Trouble Shooting / General Engine

Could be you shorted an injector ground and are flooding. Check the plugs for fuel. Are you spraying the starting fluid in to an intake port or somewhere else like at the end of the plastic snorkel? Best to remove a hose and squirt directly in to the manifold. If you're getting spark, the timing is right, and the cylinders are dry, it should start. Odds are high though that you left a big vacuum leak when you removed those "vacuum lines" whatever they are. Why would you do that, they serve a purpose? -

280z Harness Help (Plug/Wire Identification)

NewZed replied to wam8827's topic in 6 Cylinder Z Forums

-

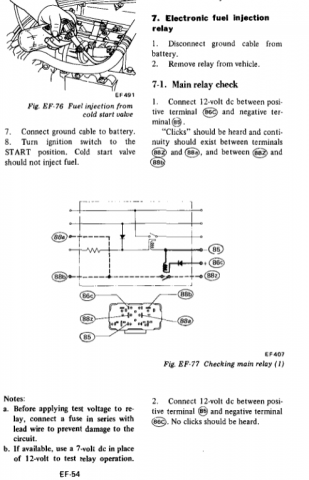

Are you figuring things out on your own or did you use the testing procedure in the Factory Service Manual? Page EF-54. The AFM switch is a common problem that can confuse people not familiar with how the system works. Those relays are hard to find but they've been seen on eBay. There are also a few places that sell replacements that work. http://www.zcarsource.com/fuel-injection-relay-280z-280zx-300zx_8_56767.html https://www.summitracing.com/parts/bck-203-0053

-

Fresh motor rebuild falls of a cliff at 5500rpm

NewZed replied to Kirkster's topic in Nissan L6 Forum

I think we're just wondering why the AFR's didn't raise a question. Should have shown as way lean if they were clogged. Your "tuner" wasn't tuning. He was just running a dyno. -

Later ZX's use an O2 sensor also. Not sure what the ECU does if there's no signal at all.

-

They changed the pins at the ECU in 1979. Somewhere out there is an explicit instruction to never connect a ZX ECU to a Z harness, or vice-versa. You can use the compete EFI system on an earlier engine. But the harness alone won't transplant. Maybe the ECU plus harness, plus some modifications to the fuel pump control. But not a direct harness swap. Use the 1980 EFI Guide if you want to study the differences. http://www.xenonzcar.com/s130/other.php