NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

How are you checking for spark? Maybe you left the rotor off? It happens.

- 6 replies

-

- Troubleshooting

- Ignition

-

(and 2 more)

Tagged with:

-

Sorry, but you're not understanding the principles of electricity. The coil has continuity from the positive post to the negative post. They're connected. Therefore, when the positive post has voltage so will the negative post. If the points are open, they'll be exactly the same because no current is flowing. One side of your points should also have the same voltage. Measure battery voltage with the key off, then measure at both coil terminals and the points with the key on. Measure resistance to ground on the other point, the one with no voltage, to make sure you have a good ground. You can also measure resistance to ground of the capacitor/condenser. It should not have continuity. With the key off, measure resistance of your coil also, from the neg post to the pos. If all of the parts measure right, and you get them connected right, you should get spark. There's stuff on youtube that shows all of this. Points ignition systems are common to all brands of cars.

- 6 replies

-

- Troubleshooting

- Ignition

-

(and 2 more)

Tagged with:

-

I think that you meant zero current when the points are open, not voltage. He'll have battery voltage when the points are open, and a voltage drop when the points are closed. Points are the switch to ground.

-

Pints work by opening and closing, breaking and making the circuit to ground for the coil. You can test the ignition system with your finger by closing and opening the points with the key on. If you set the gap when the points are supposed to be closed, they'll stay open and you'll never get a spark. Find a source on the internet that explains Kettering ignition systems. Your statement below doesn't make any sense. " I have used a ohm meter to check that the plug on the distributor is grounded and it is when the point is closed. "

- 6 replies

-

- Troubleshooting

- Ignition

-

(and 2 more)

Tagged with:

-

Post the diameter of the round exhaust ports and I can compare to my squares (rectangles). To see if it's just somebody's fancy porting job. Although that won't explain the casting stub (sprue).

-

That is odd looking. My 76 N42 has the same type of font, little 4, big 2, but it doesn't have the casting port remnant, the square stub, next to it like yours. Could be a head from Asia, from one of the JDM-type suppliers. They didn't go to the emissions heads, with liners, for quite a while after the USA did, apparently. Tony D has posted on the general topic, I believe. Maybe it's a linerless head designed to use the round exhaust manifolds that the liner heads used. The liners probably add cost and complexity.

-

Sorry I can't be of more help, but if you haven't been in to how the EFI system works, you're starting from scratch. There are several things that can affect idle behavior. Testing is fairly simple but you need to understand how the parts work individually, and how the system works as a whole. It can take some study.

-

Test the air regulator. A cold engine needs a richer mixture than a warm engine. A vacuum leak makes the mixture lean.

-

The cold start valve only operates during Start. It squirts fuel only while you're trying to start the engine. Once the engine starts it's done. Running problems after the engine starts aren't likely caused by the CSV. For about a minute after starting, the air regulator (aka AAR) should be open to keep the idle speed up. Usually though, the engine is still cold when it shuts completely. You can test the AAR to see if it's opening and closing correctly. You might have a vacuum leak. They can cause a lean condition that is more significant at idle when cold than after warm up.

-

280z Harness Help (Plug/Wire Identification)

NewZed replied to wam8827's topic in 6 Cylinder Z Forums

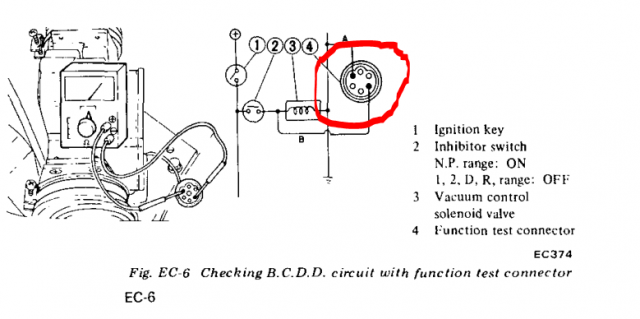

Show the plug side of the plug, not the wire side. And FSM means Factory Service Manual, you're not using Chilton or Haynes are you? Get Factory, Open Emissions chapter, go to BCDD section. I said "kind of" because you didn't show the telling part. That port is right next to the coil and distributor wire connection block. It's an odd one and looks like it should have a counter part connector. But it doesn't, unless Nissan has a machine that automatically tests. Maybe they do it during assembly. -

280z Harness Help (Plug/Wire Identification)

NewZed replied to wam8827's topic in 6 Cylinder Z Forums

And it's not connected to anything. It usually has a rubber cap. -

280z Harness Help (Plug/Wire Identification)

NewZed replied to wam8827's topic in 6 Cylinder Z Forums

Kind of looks like the test port for the BCDD. Check Emissions chapter. Also shown in the wiring diagram right across from the Air Flow Meter (AFM). These cars don't have a MAF sensor. The MAFS can be called an AFM, but not vice versa. The diagram shows more wires because they show all versions - California, Federal, Auto, Manual. -

Fresh motor rebuild falls of a cliff at 5500rpm

NewZed replied to Kirkster's topic in Nissan L6 Forum

How did your "tuner" miss that? -

Fresh motor rebuild falls of a cliff at 5500rpm

NewZed replied to Kirkster's topic in Nissan L6 Forum

Don't the MS logs show what spark and injectors are doing? You talk about falling off a cliff and crapping out but nothing about what the logs show. That's the beauty of data-logging, you don't have to guess at what happened, only what caused it to happen. Fun to review all of your specs. but the logs should tell you what's (not) happening. Spark and injector open duration. -

-

No Start - Then Running but Rich?

NewZed replied to 78-280Z's topic in S30 Series - 240z, 260z, 280z

That noise sounds more like an alternator whine or maybe a vacuum leak in a hose. Kind of high frequency. Have you checked the air gap on the distributor reluctor? Might be rubbing. Have you checked fuel pressure, and the vacuum hose to the FPR for fuel? Sometimes the diaphragm leaks, making things rich, even though fuel pressure looks right. Pull the hose and see if it has fuel in it, or pull the hose and run the pump to see if it leaks. -

Considering all, wouldn't he really be better off going with Megasquirt? The odds of getting something that runs well at the end seem better. Even if he gets all of the wires right, he's stuck with whatever "tune" has been flashed to the chip, which may or may not be right for that collection of parts. And it's not really a JWT chip or ECU if "ecutunerguy" flashed it, is it? It's an ecutunerguy setup. Probably shouldn't even be mentioning JWT.

-

No Start - Then Running but Rich?

NewZed replied to 78-280Z's topic in S30 Series - 240z, 260z, 280z

http://www.xenonzcar.com/s130/other.php http://www.xenonzcar.com/s30/fsm.html http://www.nicoclub.com/FSM/280z/ -

No Start - Then Running but Rich?

NewZed replied to 78-280Z's topic in S30 Series - 240z, 260z, 280z

Funny, I thought you wanted to delete the first post so I ignored it. You really need to break out a meter and measure things at the ECU connector when you have those kinds of questions. The 1980 Fuel Injection Guide is the book, very clear illustrations and instructions. Or the 1978 FSM, Engine Fuel chapter. The bullet connectors seem likely. (Didn't see your second sentence 'til now). -

No Start - Then Running but Rich?

NewZed replied to 78-280Z's topic in S30 Series - 240z, 260z, 280z

You can't delete the post but you can delete all of the stuff in it. Get your thermotime and coolant sensor plugs mixed up? -

http://www.jimwolftechnology.com/ http://www.jimwolftechnology.com/tech_details.asp http://www.jimwolftechnology.com/wolfpdf/280Z31-INJ-MAF-88ECU-UPGRADE-6pg-Revised-12-11-13.pdf

-

Post the link to all of the advice you've already received. At least acknowledge the help you got, even if it wasn't enough.

-

http://www.carpartsmanual.com/datsun/Z-1969-1978

-

If you've verified ignition timing with a light then you're pretty far along. Have you examined the spark plugs to see if they're wet? You smell fuel. Could be that everything's close but you flooded it with too much fuel.

-

"Crank" and "turn over" usually mean what the starter does. Rotate the engine's crankshaft. "Start" or "fire" would be when you get combustion. "Fully crank over" kind of implies that you heard a few pops, and it tried to start, but didn't. But it's unclear. A person would crank the engine, or turn it over, to get it to start or fire. "Crank over" isn't really a thing. The key to getting any engine to start is getting all of the moving parts moving and actuating in their proper timing. The valves need to open and close, and the spark needs to happen, when the piston is in the right spot. Check your cam timing, ignition timing, and whether or not the injectors are opening. Probably good to know also, 100%, what trigger wheel you have since MS is depending on that to do all of its work. Garbage in, garbage out.