NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

The likes are that much more valuable. Who to bestow your like upon at the end of every day.

-

Stock Car Mafia's '78 280z LS2 Build

NewZed replied to Stock Car Mafia's topic in S30 Series - 240z, 260z, 280z

Soft plastic paint on a metal mating surface isn't really a good idea. It will creep and compress over time. -

You don't seem to be measuring anything. There's no numbers. One thing that many people do when they swap parts is to compare the old to the new. You could have, and still could, compare(d) the old MC to the new one. Sometimes people have to swap the rods to get the new ones to work. Added a picture. With the pedal in the proper position, one way to get really close on the MC rod length is to adjust it until the clevis pin drops in to the hole easily. And a typical test for air in the system is to pump it up. If the system pumps up, in other words works better after pumping the pedal quickly, then there's air. The pumping compresses the bubble with new fluid. Anyway, good luck. Take some time and look at each piece and what it does. It really is a very simple system. A collection of simple concepts.

-

Those hose clamps look scary. You can get CV boot clamps, and a $10 tool to fit them. https://www.summitracing.com/parts/oes-25326?seid=srese1&cm_mmc=pla-google-_-shopping-_-srese1-_-oem-specialty-tools&gclid=CMOxnZi35M0CFQeTfgodfqoH7g https://www.summitracing.com/parts/cwa-5013626aa?seid=srese1&cm_mmc=pla-google-_-shopping-_-srese1-_-crown-automotive&gclid=CN7XiqS35M0CFZNhfgodlFQK3w

-

Spray some WD-40 or PB Blaster on first to help. They rust. Found a picture of the back on the inter-tubes - http://www.ebay.com/itm/Used-70-78-DATSUN-240Z-260Z-280Z-QUARTER-PANEL-EMBLEMS-PAIR-/262514806476?hash=item3d1f1a0ecc:g:G4kAAOSwmtJXVdBb&vxp=mtr

-

They're just a press fit, with spring clips. Pry up the edges and they'll pop out. Don't know how fragile they are so use a wide blade and work slow.

-

See if you can get a decent picture of the inside of the cylinder. That's where the corrosion/crud that damages the seal or gets stuck under its edges lives.

-

The seals are only good if they create pressure. Should have checked for pressure before removing. Sorry, but it's measuring you need to do, not more looking. The problem with just replacing is that you'll still need to make sure it's all assembled correctly. But, you're in the might-as-well zone now. Might as well replace since they go bad eventually and you have it apart. Odds are decent it will work right when you put it all back together. Ttake the new parts apart and make sure they're not contaminated with honing grit before installing.

-

You need to move on from the "maybes" and "seems" and take some measurements. I had a slave cylinder that leaked in the middle of its stroke when it got hot. It seemed right, and it held pressure. Just didn't move far enough. Took me a while to figure it out. And it was a new cylinder. But it was dirty inside.

-

Coilover Leveling Issues

NewZed replied to ~KnuckleDuster~'s topic in Brakes, Wheels, Suspension and Chassis

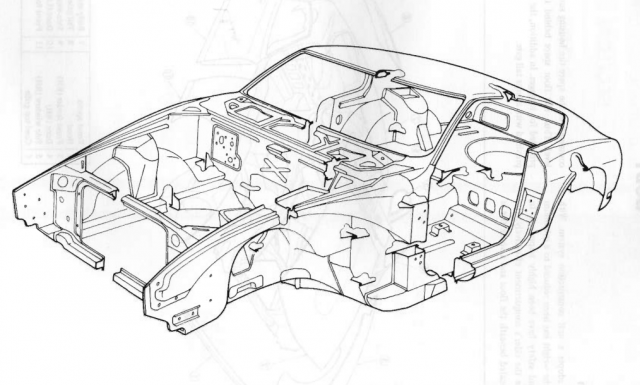

The rocker panels are the stiff part of the metal box that is the chassis. They're like frame rails, tied directly to the fender wells. The floors, not so much. -

It's just a few flakes. They might not even have left the top of the cylinder head.

-

You're not giving many details. Disassembled the clutch pedal, won't go in to gear, pedal doesn't feel right, adjust linkage every which way. It's not clear if the end of the clutch fork moves even a millimeter. See if the end of the clutch fork moves when you press the pedal. Or remove the line from the MC and see if you can generate pressure there. The cylinders are known to corrode at the ends over time. If the seal dragged over it it might be toast. The system is simple. The pedal and linkage move a piston, fluid moves through a tube, another piston moves, a rod moves, the end of the clutch fork moves. You need to determine which part isn't doing its job.

-

But does it go in to gear when the engine is running? That was the original problem. Now the pedal doesn't feel right.

-

I see it now. Worth more examination.

-

DEREK probably knows for sure but it looks like a core shifted during casting. The machining operation broke through and the QA department probably had to give it pass to let it through. Just a guess.

-

No pictures of rocker arm pads. Just cam lobes. They don't look terrible.

-

You might have ruined the seal in the MC when you let the piston come all the way back when you disconnected the pedal, or sucked some air. Or you put it back together incorrectly. If you're sure the mechanicals are right the best you can do is to bleed the system and hope. There's a chapter called Clutch (CL) in the FSM.

-

The only way the replacement axles would be twisted is if he sent you a pair that somebody else twisted and returned. Hope you used Paypal, and don't let the time limit run out. He might be stringing you along until time runs out and you can't get your money back. The BS about the twist being in the design doesn't bode well for you.

-

Those axles are ruined. They've twisted and you're trying to insert them in to straight splines. They were only engaged at the tips while you were using them before because they weren't held in by the circlips and slid out. Looks, also, like they may have been twisting even when they were fully inserted, since the twist extends the length of the splines. Might have worked their way out as the twist grew. Insufficient heat treatment maybe, or just too much torque and tire..

-

Their comments about regulators are vague and not worth much. A proper regulator setup will maintain pressure. Do you have any regulator at all? The symptoms they describe are for fuel starvation, not over-pressure. If you don't have a regulator then you could have 7 psi at the carb, but only if there's a restriction. You could just measure pressure.

-

The 280Z tach works from voltage, not current. So you'll have to wire it correctly. Offer some clues about how you wired up the ZX system and what, exactly, the tach does or doesn't do, and you might get some help. It wasn't even apparent that you had the distributor installed from your first post. And "doesn't work" could mean almost anything.

- 4 replies

-

- distributor

- tachometer

-

(and 3 more)

Tagged with:

-

Some people have no problems, some do. There's no real tricks to the conversion, the ZX module does what the points used to do. The tach still sees the current flowing in to the positive post of the coil. Try it and see what happens. There's a guy on another forum who said that he had zero issues with his 240Z, it was a simple problem-free swap. The MSD system is different in how it pulls the current to load the capacitors, I believe (guessing). It pulls less or more or not as cleanly.

- 4 replies

-

- distributor

- tachometer

-

(and 3 more)

Tagged with:

-

This should answer the first part - http://www.atlanticz.ca/zclub/techtips/wiringdiagrams/78_280Z_wiring.pdf Many people add relays to the headlight and the running light circuits, to take the load off of the switch on the top of the steering column.

-

Sure, let's see some evidence from Audi about a pre-filter. Not a strainer, with big holes, but a filter for small particles. I've seen the in-tank plastic screens used on the in-tank pumps. Not the same as that G3 paper filter. The basic point is understand how the pump works and what it needs. You've just gone a bit hyperbolic in your recommendations. And a lot of these guys are using pumps with flow rates much higher than they need. What L6 out there needs 255 LPH? That's over twice what the stock pump produced. It's just not needed. Pretty sure that Nissan used the same fuel pump for NA and turbo engines. No offense to anybody out there using the 255 pump. But it seems to lead to more problems than it's worth.