-

Posts

2366 -

Joined

-

Last visited

-

Days Won

27

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by madkaw

-

For anyone still following this; Beautiful day here in Bloomington Indiana-high 70's and not much humidity Current set up is; pilots are 62.5's at 1.5 turns out. The engine is happiest at this point. NO hesitation or bobbles and AFR's hovering around 14. The engine idles best here and restarts the easiest. The 65's semed too rich and made my wideband go crazy-whic is usually an indication that my mixture is taking big swings. Main jets are 155 and main air are 180. Since my O2 doesn't like big swings it is a bit more difficult to diagnose the main side. Plenty of power, but maybe more is available. Accelerator pumps; went back with the 40's and the engine likes it. There is no bobble when bipping the throttle or heavy tip-in. With the 47's the engine sounded like it was drowning in fuel. Back to more R&D

-

Can someone tell me how the main air jet and the main fuel jet interact with each other. When I was expressing to Todd about richening the main side he suggested sizing up the main jet and dropping back on the main air to the 180's(from 200's).

-

Thats what I'm feeling when I drive. My stumble, if you want to call it that, feels like the pumps are drowning the mixture. Now that I have had the carbs off and have witnessed first hand how much fuel the pumps put out, I can see this happening. Jets came in today, so tomorrow us R&D day! Jon, did you wind up leaving the plunger rod in te middle hole? I also considered moving it to the lowest setting, but it's easier to change the pump jet from on top.

-

Well Todd made me deal I couldn't refuse on main jets- I think he feels sorry for me. I've got 145,150,155,160's coming. I'm running 62.5's on the pilots, still not enough - I think. Too small main jets alters my driving, don't want to run lean and my buggers mains aren't here yet. I'm thinking I'll be running big pilots with a smaller accelerator pumps- got 47's in there now and it seems to bog the motor . But I have more driving and tinkering to do. Thanks for the info Tony.

-

How the f$ck do I measure WC? That's a 3" pipe running to the box. The TMW box is 3.35" I think. Area of the box is almost twice the C.I. Yes the vent cover up was kind of dumb, but I'm just a hack mechanic!

-

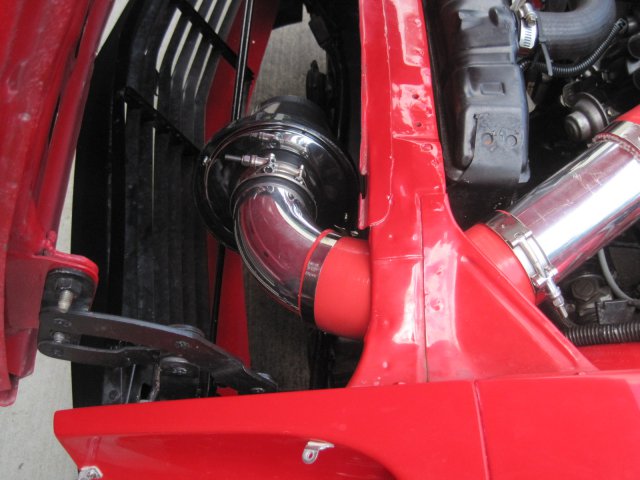

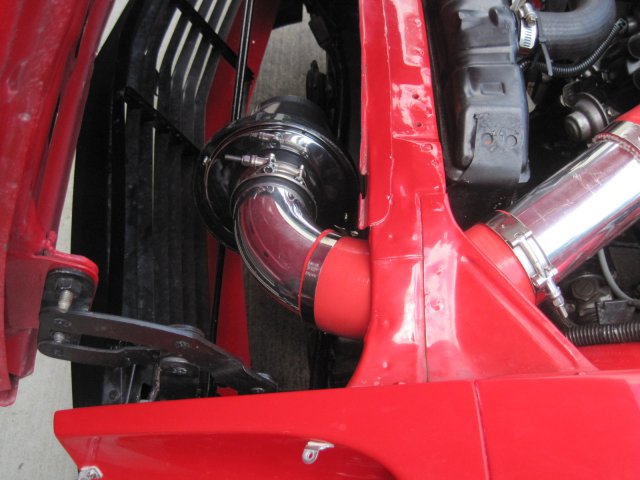

Well I thought I would update this thread with some pics. The CAI is not complete-need to be polished up, but it is in working order. I have some work to do to get my vacuum log done. It can be a big source of vacuum leaks as I have found out.

-

Well I actually got to drive the damn thing today I left the 200 main airs in and ran with 60's on the pilot side, but still had to run 2 turns out. Cruise was dead on AFR-14.5 Idle is less conclusive since the wacky O2 sensor-but 13+ I will guess WOT is where it needs work, with 140 main jets I was at 16+ AFR It wasn't very strong with those AFR numbers, but straight cruise wasa delight Yes there was a slight stumble, but I believe the 62.5's might get me there. Jon, doesn't look like a big difference in pilot size despite the vent deal. Of course it doesn't die now and I never had it out on the road until now. The airbox seems to be working out, but I have work to do on my vacuum log

-

I guess I should have posted a pic earlier and you guys would have figured it out for me! I feel kind of dumb, but live and learn. Atleast it was an easy fix. Still putting it back together so I haven't driven it yet.

-

Figured out my issue, but I'm going to make you guys figure it out. Tod really liked my CAI, but it has/had a serious design flaw-that's your clue, along with a pic

-

Any links to threads showing this process? I would be very interested in doing that later.

-

Thanks for the insight Tony and FI is in the future, but I want to say I've done triples! I'm awaiting a return call from Todd. He left a voice mail suggesting I remove the jet cover and try it again, not sure what that does. Of course I'm on a train and try anything right now- plus my car is still on jacks awaiting my Cibie headlights to arrive and to install. At this point I probably need to drive it to see what it does or does not do.

-

Pete, I stumbled upon a very clean e-31 if you need one-- very clean! I'll add that I would have voted for the 25ett

-

Did you disconnect the cables and checked to make sure the linkage is not binding? The linkage piece that connects to the bottom of the jet nozzle utilizes a special washer that allows them to pivot. If the washer is not there or the wrong one the screw will tighten down preventing rotation and freedom of movement.

-

I concur on the main air jet thinking, but I obviously have a lot to learn. An added note; every once in a while my flakey wideband works and I saw decent AFR's at idle with the 65's, but it still stumbled to death . I need to go back at it with fresh plugs and an open mind. If it wants bigger main air I'll get it. I will eventually get back to Todd on this, but his info usually comes complete with a lecture;)

-

Okay, got some 62.5's and some 65's today. Didn't even bother with the 62 at first, just threw in the 65's. Engine ran a bit better, but still fell on it's face with 2 turns out. Wouldn't idle with just one turn Now I'm pulling out my hair thinking I still have other problems and I don't have anything else to try. When I received the carbs it had 2 sets of main air jets, 180 and 200's. I have been running with the 180's so I decided I would try the 200's. Wouldn't you know it raised the threshold of the stumble by atleast 1500 rpm, and I can about save it with a little more throttle. I ran out of time to do more troubleshooting, but the larger main air did help! Thoughts?

-

I should have stated that I already replaced them. When I pulled these out I thought I had found my issue and got on the phone and ordered new ones. The new pilot screws went in with the 60 pilot jets-but still too lean. I have actually found several issues with these seemingly "new carbs", but I think I do have a very nice set.

-

-

63.5's and 65's are on the way! Last trip around the block was an embarASSing barrage of coughs and sputters and I thought I was going to have to push the car up my steep driveway

-

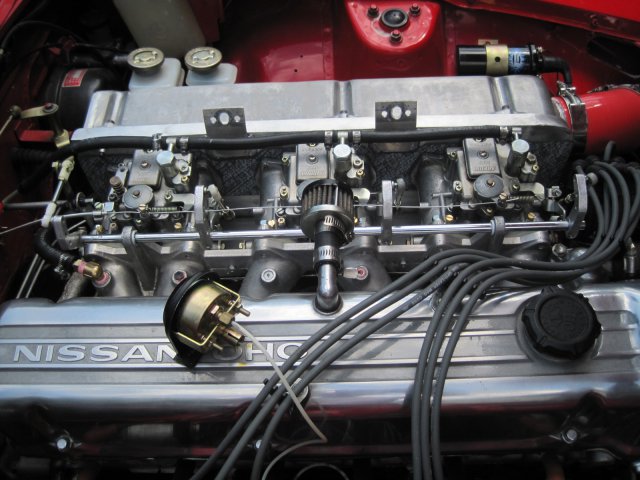

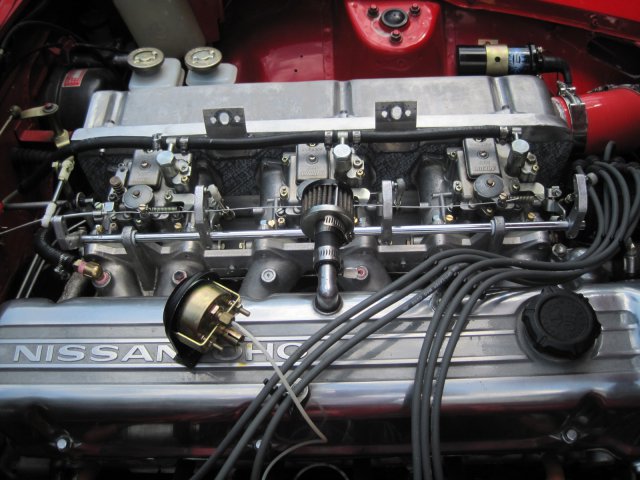

Schneider 274f I believe-480 lift 270/270 Then you throw in dual 50mm exhausts Larger valves Mild port Unschrouded chambers and notched bores I don't know if there is a way to guess, but just try different sizes Sidenote; Just got off the phone with Todd and he made a general statement that the smaller carbs usually wind up taking bigger pilot jets then say a set of 44's. He also believes I should just get out and drive it since a no-load scenerio sitting in the garage might be decieving. Maybe, but I know that an engine shouldn't die under no load just acclerating the throttle in the garage either, and my garage is to steep to be screwing around with a car that stalls. So I have the next 2 sizes coming And Tony, as far as timing I am running 20 initial and 37 full

-

Yes, 1 turn= 360 degrees, so 2 and 1/2 turns =900 degrees My car will not run with just 1(360 degrees) out-not even close. 900 degrres out gets a nice idle, but that's it. The throttle opens into the progression hole area and it's done(dead) 57.5 is a bit arbitrary, but a lot of threads where guys posted their pilot#'s , they weren't to far off or smaller. Todd at Wolfcreek thought I should be "in the ball park" My wideband O2 sensor is a bit erratic, but when it is stable, it is showing lean-like 16+ As far a booster venturi's-I might need to school myself on that subject-I'm not sure what you are exactly refering to. Time to search, though it sounds like that is not my issue.

-

Was that a L24? Did you exhibit my symptoms with the smaller jets? I have seen sizes all over the place, but usually smaller then 60. I guess every engine is very different! Learning about Mikuni's the hard way I guess.

-

Okay, I'm still having the dead spot. What I have done is: Removed carbs and checked and cleaned accelerator circuit-all carbs are firing a steady pee stream with the slightest of throttle movement.(pumps set on middle hole) Blew air and carb cleaner thru the pilot circuit and I can feel air coming out of all pilot holes-idle and progressive holes. Installed 60's pilot air jets-seemed to best around 2.5 turns to 3 Sprayed carb cleaner around while running-no significant change All O-rings were in good shape between carbs and intake Removed ALL sources of extra vacuum-brake booster and PCV and removed vacuum log-plugged intake Can get a very smooth idle-even down around 800rpm. Engine will rev-up nicely, but still will die doing a very small, steady opening of the throttle. I even threw the 57.5's back in, no real change. I pulled the plugs after all this horsing around and some did show rich. It was kind of odd-1.3.6 were cleaner then the other 3?? My wideband is a bit sketchy right now, I think I need a new sensor. Most of the times I had the best idle it was showing lean. IT was a challenge to get it below 14 and then it seemed to load up trying to get it any richer. By then I had 3 turns out on the pilot. So if I had a vacuum leak somewhere, would I still be able to get such a smooth idle? I have searched at many set-ups and you rarely see over 57.5 on the pilots, so why would mine be the exception. Would bumping up to a 62 make that much of a difference? Tony, recurving the dizzy would be required to get past this point?

-

Not sure if you know how relays work, but if you don't----try the Daniel Stern lighting website(you know-the bad guy in Home Alone in NYC). He does a nice job explaining them and give you some hints to troubleshooting. I would pull the relay and my multimeter out and start checking voltages. Are you getting a trigger voltage?