-

Posts

963 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by jnjdragracing

-

All the above is correct. Cam should spin freely to the point it wants to basical slip out. Who installed your cam bearings? I had a machine shop ( I do not use anymore ) installed some for me. I assembled the bottom end of the engine. Went to install the cam no go, tried everything. Finally took bottom end back apart, took back to the machine shop to check out with cam in hand. Come to find out they had a new guy and he installed the wrong cam bearings. From now on I always test fit the camshaft before doing anything else to the motor. Hope this helps, cam should spin freely, use plenty of assembly lube. John

-

What if 20k was on the line?

jnjdragracing replied to Syndicate's topic in Gen I & II Chevy V8 Tech Board

We will enter...... I would break it down in about 6 diffirent classes. 8,9,10,11,12,13 or more second classes. Then run a bracket race for each group with a payout of $1000.00 per 2nd place, then $2000.00 1st place. Then group the winners together for another bracket race. You must dial in your car and if you run faster then you loose. Then have the finales with the faster cars spotting the slower cars with a 3rd place, 2nd place, then winner with dollar amounts. You will choose who runs who with a draw. Example draw one name, then another they run with a dial in. etc.... Payouts would be up to you. I would not allow electronics, like throttle stops, but have them foot braking, no trans brake etc. It would make for an interesting race. I would only except door cars, no dragsters or pro mods. Just some ideas....... Like I said, count us in. John -

Good run, enjoyed watching it. I would give them another try at a well prepared track. John

-

Added more info at bottom....

-

We worked with ujoints for a long time. We tried various configurations as well. The main problem with ujoints is the angle of load. Need to setup the car squat when launching for the ujoints to be straight, not in a bind. We finally went to cv joints and have had great success with them. My brother Jerry finally achieved the 1/8 mile in 5.8 seconds on ujoints which was his goal. Did 1/4 mile at a best of 9.21 at SEZ#6 with ujoints. To me they are too unpredictable. I have seen them break to often and it takes a hard digger to the left, we usually would break the drivers side. But at SEZ#6 we broke both at once. I would highly recommend CV joints. Oh I forgot to add, with the CV joints our best 60ft. to date has been a 1.32 60ft. The original CV Joints halfshafts with Modern Motorsports Companion flanges are still on the car with out failure so far. So I guess we are a pretty good test to what would hold up under drag conditions. I hope I did not jinx ourselfs for Pinks All Out - Bristol TN. John

-

1 QUICK Z to Run in the " KING of THE STRIP''

jnjdragracing replied to 1 QUICK Z's topic in Gen I & II Chevy V8 Tech Board

Hey Jon, I watched the 1st episode.... Barney is a whiner. Then watched your 1st episode. Man the lady is a Bit&^. I am glad to see you whip her. Why was she even on the show? To me it is a semi stock car. Nobody wants to see that IMO. Oh well guess we will you and your team at Bristol next Friday. John -

*Vids* First Time At The Drag Strip EVER!!

jnjdragracing replied to Z U L8R's topic in Nissan RB Forum

Great job, I bet it want be your first time at the track again. It gets addicting, addic for speed. John -

Brake upgrade but no peddle pressure..help

jnjdragracing replied to jerryb's topic in Brakes, Wheels, Suspension and Chassis

This is exactly what I was going to say. We did it and had the same symptons. Make sure the calipers are correct. John -

Spark plug wire length...which set to buy?

jnjdragracing replied to THUNDERZ's topic in Gen I & II Chevy V8 Tech Board

I run the MSD 8.5 mm plug wires, universal set. You cut them to length and install / crimp the dist. boots on them for your application HEI or Old style. I route my wires under the headers to get them out of the way. I have not had any issues with them. Since I run the MSD ignition, coil, timing computer, Dist. I thought I would keep the wires the same. The universal kit comes with the strippers / crimper block to use with them. Also if you make them yourself or before installing ready made wires, always Ohm the wires before using. This way you know the wires are good. Normally a 8.5 mm wire should be 50 ohms or less per foot if I remember correctly. Hope this helps..... John -

ebay parts collection - Got $1.5 Million to spare?

jnjdragracing replied to Trevor's topic in Non Tech Board

It is like Heaven to me too. Wish I had the money to offer something. Not 1.5 mil. but about half the amount. Then spend the rest of the time cleaning, cataloging, then selling. John -

****vote For The Best Custom Z Diecast****

jnjdragracing replied to MOTORHEAD427's topic in Non Tech Board

My vote is for RoxZ. John -

I totaly agree, ask for another hood / exchange or a refund of some money back and fix the hood. They sure did mess the hood up, I guess they do not trial fit before selling. I would be upset. John

-

As BRAAP mentoined, I would weld the whole thing up including the spider gears to each other. Yes I have welded ours up and seems to be holding. Also as mentonied I would replace that carrier with another one. John

-

Yep looks like it is time to weld it up solid, then covert to cv joints. 60ft. times are good. John

-

1976 280Z, see it at www.jnjdragracing.com. Also have a 1971 240Z, project car. Have not started on it yet. It will have a chrome moly tube chassis, narrowed 9 inch 4 link. I will convert the superchager to alky injection at that time. John

-

anyone mount a parachute on a 240z?

jnjdragracing replied to roller's topic in Brakes, Wheels, Suspension and Chassis

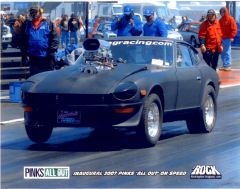

On the Zcar Steve and I built we mounted it to the rear Roll Bar. Where the roll bar attached to the rear of the car, then mounted the roll bar tube coming out of the rear. Attached is the only photos I have at the moment. Hope this helps. John -

Help. how do i cut a hole in my hood??

jnjdragracing replied to MAXIMUS's topic in Body Kits & Paint

This is what I would do, after you get the intake, carb, breather on. Take some white lithium grease and apply to highest point of breather. Gently close hood to make a pattern. Then use a drill to cut some 3/8 holes, then use a jig saw to cut out the pattern. I would apply some masking tape to the outside of the hood to prevent flaking of the paint. You can also attach masking tape / rag to the jig saw giudes to prevent scraching. Go slow and take your time. John -

Awsome looking Z Stony. It already looks like it will run in the 9's or 8's. Don't despire, you can find the time to finish it. Wish you were in SC, I would love to be able to help you finish it. John

-

I have indexed plugs before when we had a nitrous motor, really did not achieve that much. Here is a couple of good articals that explian it. They make an indexing tool which is easy to use. Follow the links below: http://www.automedia.com/Indexing/Spark/Plugs/a/pht20001001sp/1?gclid=CMGrk5ex7owCFSMKGgodihao7w and http://www.automedia.com/Indexing_Spark_Plugs/pht20001001sp/2 john

-

1 QUICK Z to Run in the " KING of THE STRIP''

jnjdragracing replied to 1 QUICK Z's topic in Gen I & II Chevy V8 Tech Board

Hey Jon, Jerry came back home today. He was in Nashville TN. and had another episode with his stomach, thought he was going to have to go to the Hospital. He got ot feeling better and came back today. He is expericing the same Intestent thing he had sugery on not long ago. Then he was hospitalized again with an episode. He is going to another GI doctor Wed. for another opinon, hopefully will get it straighten out. If he has surgery again, hopefully he will have a quick recovery in time for Pinks all Out in TN. I will have to drive / race, which is not a problem. Just wanted to inform you. John -

We use the autolite racing plugs for our application. Although we have used the NGK racing plug as well. Have not had a problem with either one. Remember you need to run the correct plug for your application ( Heat Range ). The racing plugs in our case are a little shorter ( stubber ) this helps with clearence issues. You can go to: http://www.autolite.com/products/racingHiPerformance.php or http://www.ngksparkplugs.com/products/spark_plugs/racing.asp?mode=nml for the description for the different types of plugs. It is what I can get my hands on when in need and price. Hope this helps.... John