-

Posts

1384 -

Joined

-

Last visited

-

Days Won

12

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by rossman

-

If you are talking about the gauge on the red anodized part it is a fuel pressure gauge. You don't have to replace it but it can be purchased separately from the fuel pressure regulator. One of the wastegate hoses runs to a boost source (intake manifold, turbo outlet, etc.) with a boost controller in between. The other hose is usually open to atmosphere. What kind of wastegate do you have? The hose to boost source should be on the side of the wastegate diaphragm that will cause the wastegate to open when boost pressure is applied. I hope that makes sense.

-

How to replace a crank pulley (harmonic balancer)

rossman replied to nelots86's topic in Nissan L6 Forum

It can be removed and reinstalled without removing the front cover. I've done it before. -

How to replace a crank pulley (harmonic balancer)

rossman replied to nelots86's topic in Nissan L6 Forum

You should go ahead and replace the front seal while you have the damper off. It's not critical but it's easy to do at this point. -

I suggest you do some searching. All of your questions are answered elsewhere in this forum. You can weld the internal wastegate flapper shut if you want to go external. The wastegate actuator is a simple spring diapragm mechanism that holds the wastegate flapper shut. When the diaphragm experiences enough boost pressure to overcome the spring tension it pushes on the wastegate flapper to relieve the boost pressure. Boost controllers are usually manually or electronically controlled valves that limit the boost pressure seen by the wastegate actuator and thus control the boost pressure produced by the turbo. Higher rated actuators can hold more pressure but limit the low end The main advantage of an external wastegate is that it flows better because it usually has a larger port and is separated from the turbine outlet. It can control boost pressure more accurately especially in high flowing applications. There are pleanty of guys in that power range running internal wastegates.

-

>The owner of the car told me he spent $ 250.00 just to get it programed . I don`t know how much truth there is in that I wouldn't be suprised if it cost that much to pay someone to dyno tune the car.

-

Show Off Your Engine Bay! Pics Wanted, L-series

rossman replied to philipl's topic in Nissan L6 Forum

Exactly. Since I don't know how to weld and don't have alot of fabrication skills, I think $700 is quite reasonable. Also keep in mind that the Lonewolf intake has a machined plate between the individual runners and the large diameter collector. Each port has a large smooth radius blending into the runners. I'm going to guess that that part alone would cost several hundred dollars to have machined. Is it the ultimate intake? Would it be "better" to taper the large tube? I dunno, I would need actual test data to make an informed decision. Oh, and nice manifold Nizm0Zed! -

Show Off Your Engine Bay! Pics Wanted, L-series

rossman replied to philipl's topic in Nissan L6 Forum

Lonewolf Performance http://www.lonewolfperformance.com/nissan.htm -

Show Off Your Engine Bay! Pics Wanted, L-series

rossman replied to philipl's topic in Nissan L6 Forum

Here's mine Awaiting this bad boy...If I ever find time to install it -

Dude you are lucky it didn't pull out of the transmission and get shoved thru the floorboard. I wouldn't mess around. I would replace it with a rebuilt one or a good used one. You could have cracks in it now and it is probably out of balance. Use new lock washers and locktite when you do the reinstall. MSA and Courtesy Nissan sell the rear transmission seals. Don't forget to lubriate it if it isn't already.

-

I temp installed the hub and sensor mount: http://forums.hybridz.org/showpost.php?p=1023196&postcount=11 The hub fits in the damper perfect. Is the sensor orientation relative to the outer teeth of the wheel look acceptable? I had imagined the sensor pointing thru the center of the hub. Does the sensor need to come out more, away from the front cover or is this position acceptable?

-

I temp installed my Derek CAS hub and sensor mount. The parts are high quality. I originally had a fitment issue with the hub because he fabbed it up based on his damper which is runs an air pump on the outer v-groove. The daper I'm using came off a '78 and is deeper due to the thicker a/c belt. Derek was gratious enough to modify it to fit. The sensor placement might be off a little but I think I can make a spacer to take up the difference. Here are some pictures of the setup. I plan to use this for engine timing and the distributor mounted CAS for sync. With this setup and Wolf V500 EMS, I should be able to run full sequential ignition and injection.

-

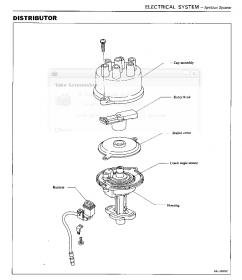

What year is your zx? If I remember correctly, '81 is mounted on the front damper and all other years are in the distributor underneath the rotor. See the picture below.

-

Cockerstar - He has a 280zx turbo. They don't have points. There is an '82 280zx FSM located here: http://carfiche.com/manuals023/cars/ Might want to check that your crank angle sensor (CAS) is working correctly. I don't know much about them so check the FSM.

-

Here is my setup. I haven't got everything together and the engine is still sitting on the stand so I don't have any dyno numbers yet... Engine: Rebello built 3.0 liter L6 turbo engine, 89mm 8.5:1 forged JE pistons, Forged rods, Offset ground l28 crank, custom ground turbo cam, Ported head with 1 mm over sized stainless intake valves Turbo System: Garrett GT35R turbo, .63 a/r T3 turbine, 3" v-band, Tial BOV, ARP Ultimate Internal Wastegate, AVO intercooler 21x8x3 core, 2.5†inlet/outlet Intake: Lonewolf Intake, 240sx 60mm throttle body Engine Management: Wolf V500 EMS running sequential fuel injection and ignition, J & S Electronics Vampire individual cylinder knock control Fuel: 75 lb Delphi fuel injectors, Aeromotive A1000 fuel pump and FPR, Modified 240z gas tank with custom internal reservoir Ignition: Derek crank mounted EDIS wheel and Ford sensor, 83 zx distributor mounted CAS with an extra hole for ECU sync, 6 individual LS1 coils mounted on a Ron Tyler (RTz) bracket Pictures, details and updates here.

-

I don't have anything new going on with the Z lately. I've had a minor disaster with my house. Apparently the brick on the north side of my house is crap and needs to be replaced. We had a couple of storms lately that pushed water thru the brick into the house damaging the interior wall some of the flooring. I got an estimate for $10K just to fix the brick . Needless to say this is putting a damper on my Z funds. On top of that, I'm putting in new flower beds that I promised the wife a while ago. The EDIS adapter that I purchased from Derek didn't fit my particular front damper. Derek was gracious enough to modify it for free. It should be here this week. I'll take some pictures when I get it installed.

-

Work on the Z has been progressing slow these days. I've been working more on the house and yard rather than the Z. Anyway, the latest work has been on the Z32 gearbox. I finally got it all back together with the modified bell housing and McKinney Motorsports mount and shifter and linkage adapter. Here is a crappy little video I shot of the shifter in action. Nice short and precise shifts. Here is a YouTube link too: http://www.youtube.com/watch?v=sLht272kDhU

-

Rev happy Flywheel / clutch choices for street use.

rossman replied to rejracer's topic in Nissan L6 Forum

I read somewhere that sprung centers reduce wear to the splines on the gearbox input shaft. Has anybody experienced accelerated wear using solid hub disks? -

I think clint78z is correct. They will all physically fit on the engine but the v-groove positions and diameters are different. Actually I haven't verified the positions (fwd/aft) are different. I have four different dampers on hand. The one pictured above. I believe it is a ZX damper. The PS v-groove was probably removed. It was on my 240 when I purchased it. I have another that is very similar. I also have one off an 81 turbo which has a bolt-on CAS disk and power steering v-groove. That one is HUGE. Finally, I have one off a '78z that is very similar to the one Derek has but, as he mentioned the outer groove is wider making the depth of the hub deeper. I will post some pictures when I get a chance.

-

MSA sells them for $239: http://www.thezstore.com/page/TZS/PROD/IA42/50-1290

-

How much can I port an internal wastegate?

rossman replied to Noddle's topic in Turbo / Supercharger

Curious, what size is your wastegate port before and after? Also keep in mind that the wastegate housing also affects amount of flow that is bypassing the turbine. You could make the hole 2" but if the housing is too restrictive it won't do much good. If you want to keep the internal wastegate you might consider a larger more tapered exhaust collector. I have an ATP "Ultimate" Internal Wastegate. It's not running yet but hopefully it and the slightly over 1" wastegate port will flow enough to prevent boost creep. -

Very nice. I wish someone offered a performance 2-groove damper. I got to have A/C living in South Texas!

-

Option 3 sounds good. PM me your mailing address and I'll send you all the parts. Once I started looking at all the different dampers Nissan used on these engines I started to realize that the design might need to be tweaked. Once I tried to install it, I knew the design needed to be tweaked. I am perfectly willing to fix the problem myself but I have limited tools and fabrication skills. I appreciate you taking ownership of your design. I am a mechanisms designer and I feel the same way. If something I design doesn't work I'm going to fix it and fix it right. Cheers, Ross

-

I'm having a few fitment issues with mine. For reference, my damper came off a '78z. First, I had to turn down the OD of the hub that fits inside the damper to get it to fit. Problem solved. Second the 32-1 flange bottoms against the damper and there is a small gap between, what I would call the mounting flange were the bolt head sits. Is this correct? Should the large washer go under the bolt head or between the hub and the damper? Lastly, the VR sensor doesn't fit between the mounting bosses on the bracket. Maybe I have the wrong one? You can see here that the 32-1 wheel flange sits flush on the outer v-groove flange: Barely visible, there is a gap between the bottom of the mounting flange and the hub: The VR sensor I have doesn't fit between the posts: It looks like that if the VR sensor did fit between the posts it would be positioned too far in towards the engine: What do you think is causing these problems? Am I using the wrong parts? Also, let me say that these are great parts. I am very happy that you produced them for these old cars. I can imagine that there are lots of different combinations and it's difficult to capture them all in one design. Cheers, Ross

-

I'm going to guess that Derek is concerned that it might be too flexible sticking out that far. If the mount hits a natural resonance from the engine vibration it might move around too much or worse wack the 32-1 wheel. You want it very stiff. My $0.02.

-

This morning I ported my GT35R's wastegate port and ATP ultimate wastegate housing and installed the turbo on the engine. The turbo's wastegate port had some sharp edges in the bottom where the drill tip stopped. I smoothed out the edges and opened up the hole about .06 on the diameter. The flapper is 1.31" so it should still have enough overlap to seal. The ATP Ultimate Wastegate opening around the turbine exit was a little too small so I opened it up a little so the exhaust stream doesn't hit the edge of the housing ID. Here is the wastegate port as received from ATP. Notice the sharp edges from the drill tip. Here it is after I smoothed it out. Here is the unaltered Ultimate Wastegate housing. Here is the Ultimate wastegate housing mounted. I had to grind open the housing so that it cleared the turbine exit. Here is the compressor housing after I smoothed out the transition at the exit. Previously there was a ~.25" lip here. I couldn't get it very round cause the damn die grinder kept grabbing, but I think it's a much improved transition. Here is a shot of the GT35 turbine blades. Here is the turbo mounted.