-

Posts

2483 -

Joined

-

Last visited

-

Days Won

24

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Leon

-

I guess we'll see how long they last...

-

Stock is stainless...

-

I used stock-replacements from SI for my rebuild.

-

Checked a few more things off the list yesterday, mostly minor stuff. I did replace the NGK BP6ES plugs with BPR6ES and the Beck Arnley plug wires with some fancy-pants Magnecors. Once again, I checked my valve lash. Since I wiped a cam last time, I'm trying to be very vigilant with the valvetrain. Last time the cam wiped sometime in the first 220 miles. I had put 100 miles on this one and it was time for the moment of truth! I was ready for anything but this time the lobes and rockers look healthy. I'm going to keep carefully monitoring valve lash and wipe patterns because I think that was the reason for the last failure. This cam profile uses a LOT of the rocker pad and you have to be extremely careful with setting wipe patterns, hence the 4 different lash pad thicknesses I utilized with this head. Also, I learned that valve lash trick I mentioned earlier that may have led to improper lash settings previously. I buttoned everything back up and went on a fun cruise around the neighborhood. This is the first chance I've had to just wind the car out on some windy roads and damn did it handle great! It's also the first Z I've ever driven that doesn't fume up with the window down. I did discover that I need to change my fuel pressure regulator and probably the O'Reilly's-special fuel pump. The regulator needs to be backpressure style so that it actually works and keeps the floats full.

-

Are California Datsun 240z control arms any good?

Leon replied to samuel082799's topic in S30 Series - 240z, 260z, 280z

I'm thinking of buying these so I'm curious, are you making these adjustments on an alignment rack with slide plates or something equivalent? -

I just don't get the point of dumping rubbing alcohol into your tank, especially if you'll never run it that way. Tune it for pump E85 and extrapolate your timing and fuel tables from that. Fill up and do your tuning at the end of summer when ethanol content should be highest. Start with a few gallons of E85 in the tank and then mix in E10 to tune at lower ratios. That alone will take you at least 3-4 hours on a good dyno to get it close, and that's if you're starting from a decent base map and just doing WOT tuning. Expect the better part of a day to get part-throttle, accel enrichment, etc. mostly dialed in. With what you want to do, you'll need multiple days of dyno time to do so, and for what purpose...? I've done many similar projects, just trying to give you some perspective.

-

Nicely done! So you're telling me that you'll be running your car consistently on rubbing alcohol or is it a one-time thing just to see what it makes? That's why I was curious if MS3 could do flex-fuel. Sounds like you're all set! Looking forward to see the results, doesn't seem like Z-guys really go for E85 much. That stuff is the best bang-for-the-buck mod you can make on a forced-induction engine IMO.

-

Nice! Where would you source E100? "E85" can range anywhere from about E50-E80 throughout the year, FWIW. Looks like your attachment didn't work...

-

Nice! Does MS3 have flex-fuel interpolation capability?

-

Hey Austin! Yeah, it's easy to let a project sit by the wayside unfortunately. I did a few things here and there but the big stuff was too much until I got a week off at home! I'll be tying up loose ends on weekends as much as I can now, I'd love to have it dialed in by summertime. Hope all's well with you!

-

Thanks Steve! Hope all is well with you and your Z!

-

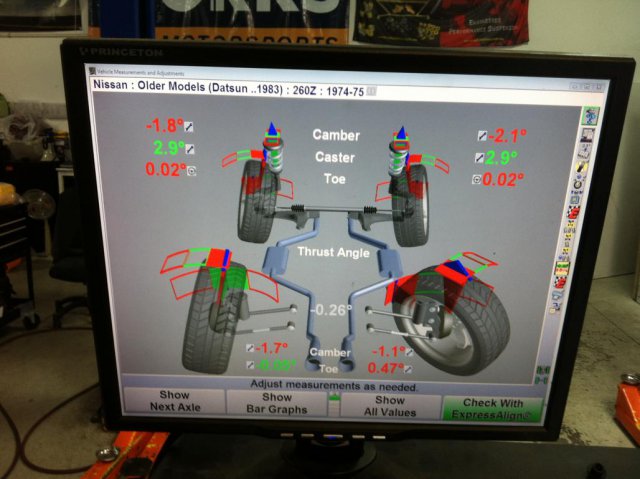

We started fresh on Sunday morning! Leo (Datsun_Z240) and Yoshi (yoshi_w) were back again helping out as well. The agenda was: (1) Install Bilsteins and camber plates (2) Corner balance and alignment (3) LSD install The Bilstein install went well, very straightforward! The gland nuts worked out perfectly. We made spacers for the Bilsteins out of scrap pipe. I deduced that the struts have not been sectioned as the inserts we pulled out were the stock-replacement Tokico BZ3015 and BZ3016. We also found some nice labels on the springs in the process, showing the spring rates as 250/275. Here is one of the upper shock mounts that came with the Tokicos, not sure where they came from. The spacer length required for the P30-0032 VW Rabbit Bilsteins in stock 240Z/early 260Z strut housings using the B4-B30-U232B1 ring nut (gland nut) was 2.625" front and 4.375" rear. Leo fabricating a shock spacer: But wait, I had completely forgotten that the Bilsteins require a special tool in order to torque them! Luckily, the guys found the perfect wrench in the shop's collection! Got the nuts hand tight and used a cheater bar to set them to German torque specs. An assembled corner, with a DP Racing camber plate on top: Since the coilover collars had no locking mechanism, Yoshi came up with this clever solution! While we had the suspension out and half-shafts loose, we decided to swap the diff for the 3.9 LSD. Luckily, we caught a discrepancy before ripping anything out. The R180 in the car has snap-in axles whereas the LSD has bolt-ins. Yoshi later found out that the diff in the car is probably a 280ZX R180. I have about three pairs of bolt-in half-shafts but they were all at home. D'oh! Thus, the LSD install was put on hold... We reassembled the car and put it on the alignment rack: The front looks pretty good. The rear, not so much. I'm looking into solutions but so far am favoring getting the T3 rear LCAs help even out toe and camber. There is no sign of accident damage so I'm guessing the subframe may have shifted. At this point we were out of time, so fixing the rear alignment was also put off to another day. In the end, I was very happy the Z made it to Sonoma and back after sitting in the garage forever and that I finally got the Bilsteins in! The drive home was great, the shocks rode smoother than the (worn) Tokicos. I've yet to drive it hard but I hope to do an autocross in the coming months once things are more or less sorted! Next thing it needs is a good detailing.

-

On Friday I had dripped some oil into the cylinders, primed the oil (with the rocker arms and spark plugs removed for added safety), checked valve lash a million times, leak-checked the fuel system, and was finally ready for fire-up. But it was 2AM so fire-up was delayed until Saturday morning... An important note on valve lash: because I had wiped a cam previously, I was now on high-alert with this one. A few important things I learned: (1) When doing rocker wipe checks, install the rocker, set lash, spin the motor around, and check lash again before pulling the rocker out. About 50% of the time, I'd spin the motor once (by hand) and get a different lash reading because the rocker/pad were not fully seated. (2) When I set lash during the final install of the rocker arms, I checked it both with and without the springs that hold the rocker arms on. These proved to have a VERY pronounced effect on checking the lash. I'd set lash, install the rocker springs, recheck, and now it was too tight! It took a little while in my dazed, half-asleep state to see what was wrong but I finally realized that putting the springs on could cause a false-tight reading. The best method I found for setting valve lash was to take the spring off, set lash, put the spring on, and double-check. Much of the time, I had to wiggle the rocker arm to get the feeler gauge to fit as the spring must have just slightly cocked the rocker against the cam lobe. From now on, I will be removing those springs whenever measuring lash. Maybe this is less of a concern on an engine that's been run for a while but it concerned me enough to do it that way. Back to Saturday morning! I woke up at 7:30AM the next morning to get cracking. The Z hadn't seen sunlight in over two years! She fired right up! I only had about 1000 miles on this motor and it had sat for a while but it was definitely burning some oil. I did an oil change the day before using Brad Penn 30 weight break-in oil. I'll be switching to Brad Penn 10W-30 soon and hope the oil burning diminishes after putting more miles on the engine. I set the carbs, set the timing, did a hot valve lash check and was ready to go. Until I left my wrench on the crank pulley and fired up the motor! The stupid thing is that my buddy and I were joking about this happening the day before, considering I was doing so many valve adjustments in between other work. Off goes the crank pulley bolt and now there's a nice big dent in my lower radiator tube! After fiddling around for a while, I managed to torque the bolt back on there and off I went to Sonoma! Picked up my buddy (Datsun_Z240 on HBZ) in SF on the way. But not without drama of course! The car was hard to drive, down on power, and sounded a bit rough on the way to SF. It ended up being the crappy Beck Arnley spark plug wires which didn't seat very well on the distributor cap. Luckily, my buddy had some brand new NGKs which worked great! Anybody want some like-new plug wires? We finally made it to Sonoma by about 2PM on Saturday. I met with Keith and talked about his most recent inventions. I'll be testing out his prototype auxiliary venturis, emulsion tubes, and adjustable idle/transition circuit air bleeds once the Z is dialed in! I didn't do any work more to the car on Saturday, I was exhausted at that point. Another buddy, yoshi_w, came up as well. We hung out at the shop and then headed home for the day.

-

Hello everyone! It's been a little while (ahem...) since I've updated this thread. Well I finally have something to update about! I started a new job last week and managed to give myself a stay-cation the week before. It seems the only time I put in serious work into the Z is when I'm in-between jobs. What a crazy week it was, back to the old times of working on the Z all day, forgetting to eat lunch, and neglecting my chores! I started on Monday with three main things on my task-list (among other little loose ends): (1) Finish lash pad sizing (2) Install carbs (3) Route and fabricate fuel system I will say that R&D takes much longer than you think! It took me Mon-Fri to do all of this, although Tuesday and Thursday were short days. There was much discussion with my dad and buddies about the optimal way to route my fuel lines. Once I decided on that, much measuring, calculating, and test-fitting ensued! In the meantime I installed the re-manufactured 280ZX distributor, carbs with new linkage and manifold, and finally sized all my lash pads. My head now has four (yes 4!) different thickness lash pads in it. That was fun... Anyway, to skip the boring stuff, I present to you poor-quality photos showing the final routing of my fuel system: The hardlines, Swagelok fittings, and brackets are stainless. The rest is AN fittings and stainless flex hose. I had the banjo fittings at the carbs re-anodized black since they only come in blue/red. I'm pretty happy with how it came out but I'm planning to redo at least the fuel rail-to-carb lines. I also found out that I need a different fuel regulator as the one I have is the dead-head type. These photos are a snapshot of the car at 1AM on Friday night. My plan was to drive the car to the shop (located at Sonoma Raceway, an hour away from home) on Saturday morning so that I could do some more work as well as meet up with Weber-guru Keith Franck. Keep in mind, the car has not been run or even started in about 2.5 years!

-

We call those "Laguna pipes" 'round here.

-

Tuning part-throttle on the dyno can be very taxing on the cooling system if there isn't enough airflow available for the radiator. A WOT pull takes 6-10 seconds. You can be holding a load at part-throttle for as long as you want, the dyno cooling fan(s) must absolutely be up for it. I don't know who Matt Shue is and I'm not saying anything about his work. Just brainstorming based on my own experience here. Like I said, if your cooling system isn't holding a vacuum, there is definitely a leak somewhere. It is not a dyno operator issue, or at least not anymore. Check compression and leak-down if there's nothing obvious.

-

Chemical test the coolant for combustion byproducts. Do a compression and leak-down check. Pop the radiator cap off and look for bubbles while checking leakdown. I would have guessed that they were doing a poor job of cooling it while on the dyno but the cooling system not being able to hold vacuum is worrisome.

-

Adjusting Camber with Adjustable Plates Installed

Leon replied to Bigbrowndog's topic in S30 Series - 240z, 260z, 280z

Didn't see that originally, my mistake. -

Adjusting Camber with Adjustable Plates Installed

Leon replied to Bigbrowndog's topic in S30 Series - 240z, 260z, 280z

You have to realize the forces at play here. There's no way you're going to loosen up the camber plates and just push the struts out to decrease camber with the weight of the car on the struts. Raise the front end of the car and then give it another try. BTW, it's probably toe and not camber that's making the car difficult to move... -

Please help me buy my garage lifts

Leon replied to RebekahsZ's topic in Brakes, Wheels, Suspension and Chassis

That's a dream garage right there! -

Hell yeah! Great work Derek, way to be persistent and see it through!

-

Very nice, I like the use of bulkhead connectors there. Makes for easy engine pulls.

-

I was thinking the same thing!

-

Please help me buy my garage lifts

Leon replied to RebekahsZ's topic in Brakes, Wheels, Suspension and Chassis

It really helps to have built-in jacks on the 4-post, like the sliding ones in the middle of Hunter racks, especially if you plan on doing alignments. Looks like Bendpak has bridge jacks as an option for some lifts.