-

Posts

2483 -

Joined

-

Last visited

-

Days Won

24

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Leon

-

Another wheek/tire fitment question thread

Leon replied to Newoldschool's topic in S30 Series - 240z, 260z, 280z

The tires were different enough that the ones on the green car rubbed when put on the orange car. The tires on the orange car NEVER rubbed. The green car is untested, but once I install the camber plates it'll clear just fine. It does have trimmed rear fender lips and front valence. I don't have any good pics from the back and the orange car is no longer in my possession. I can take one of the green car sometime this weekend though, if I can remember... -

Another wheek/tire fitment question thread

Leon replied to Newoldschool's topic in S30 Series - 240z, 260z, 280z

Here are two examples, both on 16X7 Panasports. Both have 225/50-16 tires mounted, orange car has all-seasons and green car has sticky summer rubber. You can see the difference in size even though the tires are the same size on paper. *Green car has zero rear camber in this photo, orange car has -1.5deg. -

That does absolutely nothing for SUs.

-

That's awesome, I need to forward this to my wife!

-

I've always gotten content that I have not read when I click "View New Content". I use Firefox and Chrome.

-

Strange, works fine for me.

-

I vote this for comment of the year! Again, this is some fantastic engineering, great job Derek.

-

HOLY HELL! BRAVO! Can you do a valve cover with "NISSAN VTEC" machined into it?

-

car wont rev past 3500rpm, 280ZX dizzy issues on SU carbs?

Leon replied to ol doc gully's topic in Nissan L6 Forum

Do a valve adjustment. -

You sure you used the search feature? http://forums.hybridz.org/topic/57834-obx-vs-quaife-with-pixors/

-

As a double-check, I stuck a dial indicator on the block and bolted a plate onto the head to measure against (I think I got the idea from Lazeum?). After clearance checking and upon final assembly, I put the head on the block without a gasket and zero'd the indicator. I then installed the new gasket, torqued the head, and recorded the dial indicator measurement. That measurement indicates total crushed gasket thickness. If you got a good measurement of piston deck height, you can then easily calculate piston-to-head clearance.

-

I'm going off of memory, my build thread should have my numbers but my L28/shaved P90 with flat-tops popped out the deck something like ~.023". I used a Nissan gasket. Like Tony said, clay-check your clearances. It's the only way to know. I came up with something like .025" of clearance. I did a lot of reading and researching to make sure this was OK. There are some really great posts in the archive by BRAAP and Brian Blake aka "1 fast z" on the topic. Haven't had an issue so far...

-

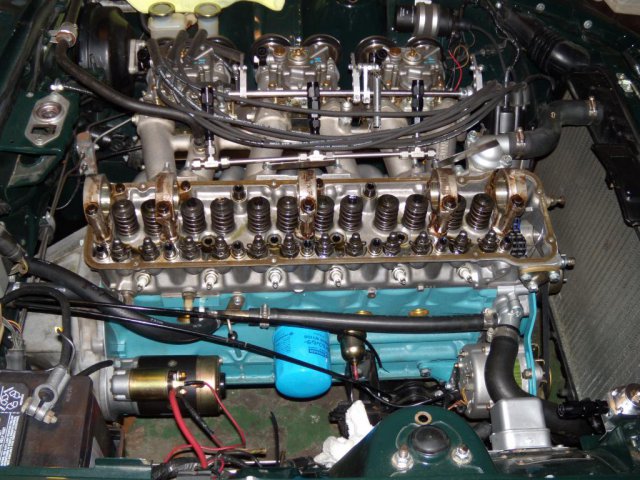

On another note, I had some time to paint the TWM intake that I plan to swap in. Paint color is "Cast Aluminum" so it didn't really change the color of the part much but I wanted to do it because painted parts are easier to maintain than bare metal. I also decided to take some measurements for the sake of documentation. The Cannon roughly measures about 145mm/5.7" long while the TWM is ~106mm/4.2". That's a 1.5" difference in length, more than I expected! This is nice because it'll open up some room between the air horns and inner fender and master cylinder. I just ordered 3/8" phenolic carb mounting blocks which will extend effective manifold length to just over 4.5".

-

Way ahead of you on that one! I probably have 4-5 flywheels and a few dozen rocker arms to play with, among other junk...

-

It's not an oil flow issue, there was no discoloration indicating excessive heat buildup. Furthermore, when initially priming the new engine I peaked through the oil filler cap hole in the valve cover to watch for oil coming out of the cam lobes, thus I know that the oil at least gets up there. Upon removal of the valve cover, the valvetrain was covered in a nice film of oil. The cam is an Isky regrind on an OEM cam. The rocker arm that failed in spectacular fashion was a home-prepped one but upon closer inspection there are signs of premature wear on a few arms, both home-prepped and Delta reground. Defects like small chips on the wear surface. At this point, only one rocker really failed but I can't say how long the others would've lasted. I bought new rocker arms from Rockauto, they are Sealed Power brand. We'll see how they hold up. I have not contacted Delta about the problem. At that time, I was in a rush and was not interested in extra headaches. Things just had to get done.

-

Oil wouldn't have made a difference, it can't fix poorly prepped rocker arms! For the record, I used Brad Penn break-in oil for the initial flush and the first ~250 miles before switching to their partial synthetic 10W-30. This was recommended to me by Ron Iskenderian. The cam was already wiped by the time the 250mi oil change came around. The oil change was done in San Luis Obispo on the way to JCCS so the parts you see in the photos have something like 1000mi on them.

-

Help me choose my struts

Leon replied to mr_han_solo's topic in Brakes, Wheels, Suspension and Chassis

Good to hear! -

Finally took the time to pull the wiped cam out. Had to remove the hood, unbolt the engine mounts, remove the clutch fan, and jack the motor up high enough for the cam to clear the radiator if anyone cares for how it's done. On a related note, I got a $15 chain tensioner retention tool off of Amazon. Saves grief and anxiety about that thing popping out. Also, I believe I've confirmed my thoughts about why the cam was wiped. I'm sending it to Isky for them to check it out and give their thoughts but it seems pretty clear. During the rebuild, I sent 12 rocker arms out to Delta Cams for regrinding, as they've been recommended countless times and they're surprisingly cheap. When I got them back, something like 50% of them were not ground parallel when looking at the lash pad contact patch vs. the cam contact patch. Being in a hurry to put the motor together in an attempt to have the car ready for my wedding (and JCCS a few weeks later) I grabbed some used rockers I had lying around and prepped them using a belt sander/sand paper on a flat surface (as shown and recommended to me by a reputable source). I inspected the rocker arms after pulling them today and could tell which ones were the regrinds and which were home/shop-prepped since Delta sandblasts the rockers. The wear-pattern on the non-reground rockers was courser than the regrinds, so to say, indicating that those rockers/lobes were possibly wearing quicker. Also, it looked like another home-prepped rocker was starting to prematurely wear. All the rockers had a distinct delineation on their wear pad between open/closing ramps, something I don't remember seeing on stock rockers. However, do note that sanding the rockers leaves a different finish than grinding. It could be that the finish has just not been "polished" by the cam yet on those non-reground rockers. Based on the evidence, I think the lobe failure was caused by a hastily-done, improperly prepped rocker arm. It's a bit strange that it took out just the closing ramp of the cam lobe and matching rocker, so presumably the contact surface of the closing ramp section of that rocker was not prepped enough in that there was still an old wear-ridge present. I assume that the reason for the rocker being worn all the way to the edge is caused by a buildup of removed material from the cam/rocker essentially extending the rocker-cam contact area during rotation. Lesson learned: buy new rocker arms when swapping cams. If you're getting regrinds, either make sure that the shop can grind them spot on, or send in two-dozen and pick the 12 best from the lot. If you're doing your own prep, do a good job! Nifty tool Offending rocker arm Offending cam lobe, opening ramp Offending cam lobe, closing ramp Differences between reground and sanded rocker I will be sending the bad cam for analysis and a good core to Isky, and will hopefully be back on the road sooner than later!

-

Look's like a '73 or '74 balance tube (EGR).

-

Greg, I'd love to have you come by the shop or my place (or both )! I'm at Sears Point Raceway by day and in San Bruno, near SFO, by night. Send me a PM, I'll give you contact info.

-

Help me choose my struts

Leon replied to mr_han_solo's topic in Brakes, Wheels, Suspension and Chassis

AJUSA was fantastic to deal with, very helpful. I will say that when placing my order back in July, I was told I got the last 4 gland nuts they had in stock. Hopefully Bilstein is still manufacturing them. As you can see, B4-B30-U232B1 is clearly a correct part number as far as ordering them goes. That's the number I gave AJUSA. For added confusion, the tops of my gland nuts say B30-629 B1... I don't remember what I paid for them exactly but it was in the neighborhood of the quote you got, so they add about $100 to the cost of the struts. It was well worth it to me. -

Help me choose my struts

Leon replied to mr_han_solo's topic in Brakes, Wheels, Suspension and Chassis

Thanks, appreciate the info! -

Help me choose my struts

Leon replied to mr_han_solo's topic in Brakes, Wheels, Suspension and Chassis

Sports are valved stiffer than HDs, I believe. After doing a ton of research, thinking, and planning, I bought a set of P30-0032 (34-184530) from AJUSA earlier this summer. Looks like they're still on sale: http://www.ajusa.com/Bilstein-34-184530-Monotube-Strut-Insert-ab061a.html Here's a link to my thread with a photo of the parts, including the correct gland nut (which Bilstein calls a "Ring Nut") part number for 240Z/early 260Z strut tubes (B4-B30-U232B1, big thanks to John Coffey for that one). This makes the Bilsteins almost a plug-and-play affair, just need to fab a strut spacer. -

15X10 Spinwerks, I believe.