-

Posts

905 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by TrumpetRhapsody

-

Spark from coil, nothing past dizzy on MSI V3 Extra

TrumpetRhapsody replied to FlatBlack's topic in MegaSquirt

Bump -

EDIS Tach Signal - Combine Negative Coil Signals

TrumpetRhapsody replied to TrumpetRhapsody's topic in MegaSquirt

Radioshack has them for 99c for two, so when I get a chance I guess I'll give this another go. I give up for now lol. -

TR's 260z L28 Build Thread

TrumpetRhapsody replied to TrumpetRhapsody's topic in S30 Series - 240z, 260z, 280z

Videos and pics to come gentlemen Something interesting.... before I dropped this motor in, I had to PB blast some rust out of cylinder 2 before I could get a full rotation out of the crank. After some blasting and coaxing I got it to rotate smoothly. When I did a compression check after getting the motor in, all cylinders (dry and cold) were 120-130psi, except #2 which was 0. After adding some oil, and cranking it longer, I got it up to 90, and eventually 100psi. Long story short I've been running this motor for maybe two weeks now, and decided yesterday to do another compression check. Dry and cold, all cylinders were within 1-2psi of 100psi. Interesting. -

EDIS Tach Signal - Combine Negative Coil Signals

TrumpetRhapsody replied to TrumpetRhapsody's topic in MegaSquirt

Hmm, that seems like a possiblity. Wouldn't that affect the running condition of the car itself though? Is there any way to test for this condition? Maybe I need... stronger diodes? -

EDIS Tach Signal - Combine Negative Coil Signals

TrumpetRhapsody replied to TrumpetRhapsody's topic in MegaSquirt

Nope, tried different diodes and tried rotating combo's of which coils I was combining. It made no difference, as soon as I add a second coil the tach dies. -

EDIS Tach Signal - Combine Negative Coil Signals

TrumpetRhapsody replied to TrumpetRhapsody's topic in MegaSquirt

Alright, progress. With the tach only connected to one coil (with or without resistor, with or without diode) it gets the 1/3 signal. As soon as I add a second coil, the tach goes dead. This is all without the Zener diode, adding it makes no difference. Is there a way to add a capacitor to triple the signal, and just use one coil? Not sure if that would work or not, I'm no EE -

EDIS Tach Signal - Combine Negative Coil Signals

TrumpetRhapsody replied to TrumpetRhapsody's topic in MegaSquirt

So you did get it working with this circuit, minus the 1N4746? Were you running the resistor inline to the tach? What year tach were you using? I'll try all that and see if it makes a difference, thanks. -

Mat's "Flat Black Z" Build Thread

TrumpetRhapsody replied to FlatBlack's topic in S30 Series - 240z, 260z, 280z

True, but they weren't reading what values the megamanual said they would. -

Mat's "Flat Black Z" Build Thread

TrumpetRhapsody replied to FlatBlack's topic in S30 Series - 240z, 260z, 280z

Actually, C9 and C10 were showing no continuity, to be technical... but who's counting -

EDIS Tach Signal - Combine Negative Coil Signals

TrumpetRhapsody replied to TrumpetRhapsody's topic in MegaSquirt

Well my wiring harness showed the blue wire I tapped into going to the negative side of the coil, so I don't think that's the problem. -

I'm attempting to use this circuit to drive my stock 260z tachometer: I'm 80% sure I've hooked everything up right, but the tach does nothing. I've tried it with and without the stock resistor inline, with no effect. My next course of action is to pull the tach and make sure it's getting the signal, and try substituting it with a spare from a 280z. Has anyone used this circuit successfully?

-

NA to turbo conversion - questions and answers...

TrumpetRhapsody replied to mikeatrpi's topic in Turbo / Supercharger

A few degrees of timing? Are you saying you can run more timing with the non-projected plugs? -

How to keep the stock tach when using EDIS?

TrumpetRhapsody replied to cachanilla86's topic in MegaSquirt

Check out the megamanual(.com) for how to do it on the ecu, or search around hybrid for how to combine the coil signals and send that back. I've seen it done both ways. -

TR's 260z L28 Build Thread

TrumpetRhapsody replied to TrumpetRhapsody's topic in S30 Series - 240z, 260z, 280z

The Holset Z lives! I'm getting a nice solid 7psi, good boost response, and everything feels very solid. I'm having to richen up my map quite a bit, as expected, but so far nothing over 50% dutycycle, and I'm getting good AFR numbers. Pics and vids to come -

TR's 260z L28 Build Thread

TrumpetRhapsody replied to TrumpetRhapsody's topic in S30 Series - 240z, 260z, 280z

My couplers came in yesterday, but I had to go pick them up from the post office this morning. I had a bit of time left over before I had to be in for work, so i went ahead and installed them. The angles aren't perfectly ideal on all of them, but they should work for now. A bit of modification and finagling and I might get a better result, but that'll be for later. After work I'll fab up a bracket for the stock wastegate actuator, and start tuning! -

MS Extra - Enhanced Accel Enrichment (EAE)

TrumpetRhapsody replied to TrumpetRhapsody's topic in MegaSquirt

BUMP. I gave up and went back to my noisy TPSdot. I'd like to start playing with EAE again. -

TR's 260z L28 Build Thread

TrumpetRhapsody replied to TrumpetRhapsody's topic in S30 Series - 240z, 260z, 280z

So the holset is officially in. I had it running for awhile, got all the shmootz burned off, everything up to temp. I'm waiting on some couplers to get the intercooler attached, and I still need to fab a bracket to get the wastegate actuator to work. Also, the hood won't close due to coupler interference, so I need to pull the IC and trim the core support to center it more. After all that it'll be BOOOOST. I can definitely say that this process was a huge PITA. It's nice to have the holset on, but I wish I had just gotten another T3 to hold me over. But, what's done is done! -

need some color help for spoiler airdam

TrumpetRhapsody replied to big-phil's topic in Body Kits & Paint

-

TR's 260z L28 Build Thread

TrumpetRhapsody replied to TrumpetRhapsody's topic in S30 Series - 240z, 260z, 280z

Well, I was talked into going ahead with the Holset swap instead of tracking down another stock T3, and I've bought some nice goodies get things going... but more on that later. I don't know why, but my early HY-35 wasn't a bolt on affair like it should have been. Aside from drilling out the bottom two flange holes (knew about that), I also have had to clearance my manifold and make a spacer. Once I account for the spacer and a gasket on each side, I should have about 2mm of clearance between the housing and manifold. I had a friend cut me a flange to mate to the hotside, and I'll need to pick up some 3" piping to custom make a d/p to interface with my current exhaust setup. Hopefully I'll be able to do most of that tomorrow. Aside from that, once the rest of my goodies get in i'll need to mock up the intercooler piping, fabricate a bracket for the wastegate actuator, and figure out a way to attach my BOV to the charge pipe (pics of that issue later). -

I've definitely kept a spreadsheet of all my plans and purchases. It's disgusting to look at the numbers add up, lol.

-

Oil Pressure problems?

TrumpetRhapsody replied to SCLOBERNOCKER47's topic in S30 Series - 240z, 260z, 280z

I have a NA block and turbo motor do pretty much the same thing. 30-40psi at cruise, but 4-8psi at idle (on a autometer gauge). The stock gauge would drop to "zero". I drove the NA motor for almost a year with no signs of issues. As far as it being normal, no clue *shrug*. -

Jeffer provided me with a cheap source for v-band clamps and flanges here: http://www.siliconeintakes.com/product_info.php?cPath=10&products_id=326&osCsid=11cc2884380436dc4101e5044ca60900 He also mentioned that the 4" had a poor fit on the Holset, and that a 3.5" would be more appropriate. He said the size reflects the ID, not the OD.

-

Anything ever come of this GrayZ? I'm starting to gather materials for my holset addition, and a DP is high up on the list

-

TR's 260z L28 Build Thread

TrumpetRhapsody replied to TrumpetRhapsody's topic in S30 Series - 240z, 260z, 280z

I was wondering the same thing, you'd think the oil filter would've caught something like that *shrug*. -

TR's 260z L28 Build Thread

TrumpetRhapsody replied to TrumpetRhapsody's topic in S30 Series - 240z, 260z, 280z

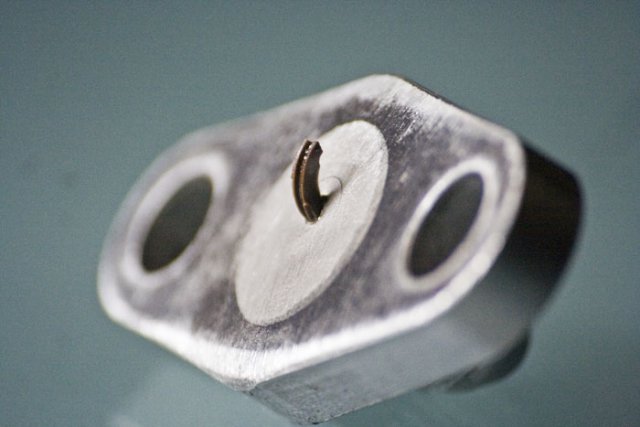

PM sent, thanks Daeron. Found the culprit that killed my turbo Seems somehow some rtv found its way to the oil feed, and blocked it. No oil to the turbo = death. I can thank the PO for this one I'm sure, dunno how rtv would get to be floating around in the oil.