-

Posts

222 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Pac_Man

-

Wow, maybe I am learning! Thanks for all the help, I have the whole harness labeled now and a much better grasp on how the whole ZX system and wiring works.

-

So could I just use a generic relay like this? Then I would wire it like so?: 30: 12v constant 87: to fuel pump + 86: ECU signal wire 85: Ground

-

Ok, I'm going to go with option 1 for the temperature gauge. I've got the ignition wires traced and labeled. Labeled the fuel pump modulator connector just so I'm never unsure about what it is or if I need it. Just did some wire tracing and diagram checking. My fuel pump relay wiring ends at the female connector on the harness. No relay or connector for it. Can I get some kind of generic relay? If my understanding is correct, I would need one that has switched 12v to turn on, ground, 12v out to the fuel pump, constant 12v, and then the connection to the blue/red (L/R) wire that goes to the ECU. Now my only question is, what is the function of the connection to the ECU?

-

Thanks again sheen. I do have the fusible links but I figured I'd just hook them into my updated wiring since, well, why not. I don't have the fuel pump relay though. I was thinking that to keep things simple I'd keep the fuel pump wired as it is stock in my car. So to connect the temperature gauge do I need to splice mine into the Y wire on that 6 pin connector you're talking about? And any B/W wire needs to recieve switched 12v?

-

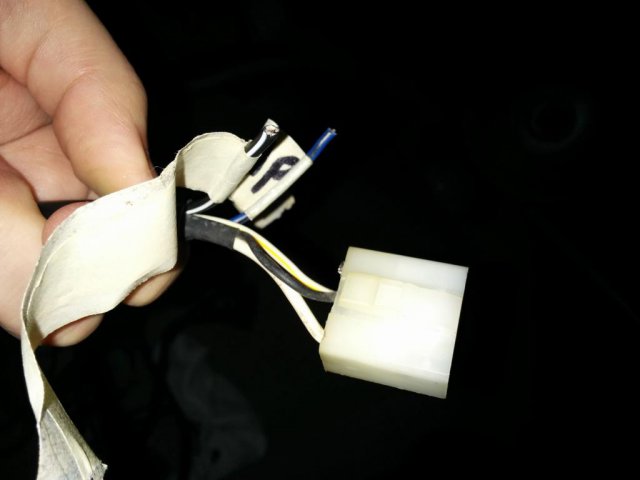

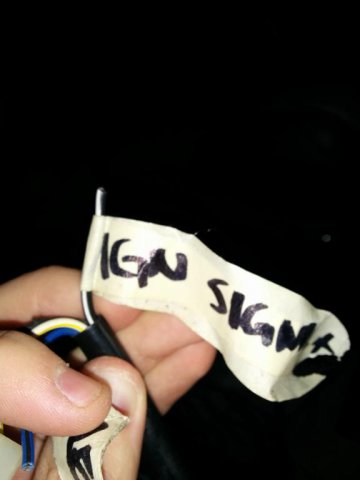

Well, I figured it would happen eventually. I'm trying to figure out the wiring before I get the engine in the car so the swap goes as quickly as possible. I've gone over the sticky as well as the more extensive and hidden version of the same thing. Harness is from an 82/83 280ZXT and going into a '76 280Z The diagrams and pictures I've seen have two plugs near the rubber firewall grommet, one for ignition (8 wire plug) and one for the fuel pump/fuel pump relay (6 wire plug). However, my harness has two 8 wire plugs, and the wires and colors do not match those of the diagrams I've seen. It doesn't even match the '83 FSM diagram. The person I bought the harness from labeled a couple wires in what seems to be the fuel pump and fuel pump relay plug harness, but I can't verify them obviously since the plugs and wire colors don't match what I've seen. Diagram that has been referenced: I'm also confused on the two wires that feed power to the EFI relay. They were connected to fusible links, but the sticky says stick them on the POS terminal of the starter. Shouldn't they be fed power after fuses? I'd assume I can hook them up to my fuses that are currently in the car (I did the maxifuse swap) but I'm not sure... Also, I'm unsure about where to wire the power wires that are in the EFI relay loom. 1 constant 12v and 2 switched 12v. If anyone has done this swap and would like to guide me on where would be a good spot to do this please let me know. Maybe I'm just thinking about this too much but I keep second guessing myself and running into weird issues like the plugs and wire colors not matching. Pictures attached show the plugs in question.

-

Typical labor rate is $100/hr +/-$10 for most independent shops from what I've seen. 4 hours to have your MS wired up and the car running sounds pretty damn good to me. Some people spend weeks trying to get everything right and still can't pull it off. $400 sounds like a lot but if you've got the cash and want someone else to do it for you right the first time (assuming they have the ability and experience) I'd say that's more than worth it.

-

8-9 AFR sounds pretty rich although it may be a necessity to prevent detonation from occurring at your boost levels with an ECU that has limited tuning capacity. A .83 housing would help but if you want to autocross the car it sounds like .63 would be ideal for you. I want to say that's what the stock T3 was on the L28ETs.

-

It's actually not cutting it that's giving me problems, it's when I try to push the fitting over it. The 8AN hose was fine but for some reason I can't get this stuff to work for me. I'm going with the stock EMS for now. I might upgrade in the future when I can afford it, but with my limited knowledge and budget I figured I should start off with something that won't get me in way over my head.

-

Well, I resolved some of my issues. I found a driveshaft for the T5 that's been shortened a little bit and also had the rear diff flange replaced with one for the non-turbo R200. This means it will bolt into my diff without needing to change out the diff flange. I've been reading that people think the 3.54 ratio diff is better for turbo applications than something like a 3.9. Anyone have any thoughts on this? Also, I realized I'm dumb and that single contact connector is for the oxygen sensor. That mystery coolant sensor actually screws into that tee fitting in the picture below it, and after reviewing the pictures I took of the engine before tearing it apart (I highly recommend doing this), I found that it goes in line to the heater core hose. So, this leads me to believe it was for some kind of climate control doohickey in the ZX which I obviously won't have. I looked at my engine and the hoses just go straight from the lower radiator hose neck to the firewall so I don't have to worry about it. I replaced all of the injector connectors since mine all had chipped plastic and were missing the clips. Also grabbed a couple extra to replace the coolant temp. sensors while I'm at it. In the meantime, I've finally replaced the fusible links in my car with the maxifuse distribution block, as per the famous AtlanticZ writeup. For the time being it's held in with zip ties but hey it was 12:15am after Thanksgiving when I finished it! I'm still going over diagrams of both my car and the 83 when I have time. I feel like I'm getting closer to the light at the end of the tunnel but I'm still stumbling in the dark at this point. After going through the EFI Bible for the first time I understand a lot more about the functions of the different sensors and such in the system, and I think I'm closer to figuring out how to wire power to the 83 turbo harness, but ignition is still way over my head at this point. I've also gotten the external wastegate flange on and got an oil drain line hooked up. I can't get the nylon/steel braided 4AN line to cut without fraying and becoming useless so I'm going to try straight up steel braided line. A bit flashy for my taste but at this point I just need something that works. I'm getting close to the point of being able to bolt the flywheel/clutch and transmission back on.

-

Ah ok, I didn't even realize you'd gotten an aftermarket tee fitting.

-

has anyone installed Rx7 brakes?

Pac_Man replied to andyhorror's topic in Brakes, Wheels, Suspension and Chassis

Sounds like a good plan. I'm sure you'd need some kind of adapter bracket but it shouldn't be too difficult to make it work.- 59 replies

-

Left one is cylinder head temp. sensor. The right one is knock sensor. Oil pressure sensor on these motors is screwed into a T fitting which is what the oil feed line screws into. Let me know how that kit works... Everything I've read says the T fitting is BSPT and NPT won't work. It's strange, though... I ordered a 1/8" BSPT adapter and it's too small. I think mine is 1/4".

-

Just a word of advice, I bought a kit and the door seals are way too thick. Had to slam my door and ended up shattering my window after a while of doing that. I went with the Kia Sportage weatherstripping option for the door and it's awesome.

-

I went with the setup I suggested, found sellers in the US to cut down shipping times (parts from China will be cheaper but can take a while to arrive... expect a week minimum usually 2 or more), and got everything for about $47.

-

Plus, that has an NPT fitting on one end. The stock oil tee fitting is BSPT. I also came up with a measurement of ~4 feet of line today by doing a rough measurement. Generally you can only order in increments of 1 foot anyway. I think those 36" kits are directed toward those with 4 cylinder engines.

-

I've been looking into this myself recently and this is the best I can come up with. One of these (T3 AN4 oil feed flange with a 1mm restrictor): And a couple of these (45 degree AN4 fittings): And one of these (1/8 BSPT to AN4 adapter): And of course a few feet of line. Not sure off the top of my head how many feet you'd need but I'd guess somewhere in the 5-6 range. Always better to have some left over though. That's the best setup I've been able to come up with with very little work. Basically a plug and play option. 1mm restrictor was the smallest I could find.

-

Is this cam going to screw up a turbo L28 motor?

Pac_Man replied to Badler's topic in Nissan L6 Forum

+1 the biggest issue here is what you're using for engine management. You won't be able to run that cam properly or run 15 psi with the stock ECU. And your exhaust setup seems fine for what your goals are. -

If it has this transmission: You will also need the driveshaft and differential (or at least the flange) as well. Shortening the driveshaft about an inch seems to be the general consensus for early Z cars, though I have heard you can make it work by cramming it in. I feel kinda iffy about that though.

-

You can get adapters to go from metric to AN fittings. Banjo bolt should be 12mmx1.5 pitch BNPT. Not sure about the other side where it bolts into the T fitting on the block but I get the feeling it's 6 or 8mm. I'll check the nut size with a wrench later when I go work on my engine and that should tell me the thread size. Then get a couple adapters to go to a proper size. The stock feed line is around 3/16" ID so you wouldn't want to use anything bigger than AN-3 for the line. Even AN-2 should be fine but might as well stick to what the car came with right? Then it's just a simple matter of getting some braided line (you can buy this on ebay by the foot), some AN fittings, and putting it all together. AN fittings are a breeze to install.

-

Hi, I'm looking at a driveshaft I found and based on the pictures it looks like a T5 driveshaft that's been cut and shortened on one end. To my knowledge, they're the only ones that neck down at both ends, but this one only has that at one. It also has the square diff flange and seems to have a 26 spline tailshaft yoke based on the blurry picture I got. Can anyone tell me for sure that it is/isn't? Thanks.

-

- driveshaft

- 280z

- (and 5 more)

-

76 tank should work too. I don't think they changed it until the late 280z in 77.

-

I'm almost positive that the 77/78 2+2 had an option for a manual 5 speed. I recall something about the fuel tank size being changed in '77, though I'm not sure how this affected the spare tire. I have a '76 and I can fit the original size wheel and inflated tire in the spare compartment. Good luck with finding it, the 2+2 is not a common one.

-

Have you considered a tank from a 280z? I don't have an extra but they are a bolt-in replacement and have baffles. Would come in handy if you ever go for more horsepower down the road.

-

Title says it all, really. Found out the guy who sold me what was allegedly a t5 driveshaft and diff didn't know what he was talking about.

-

Well, a couple of issues have reared their heads... 1) I'm pretty sure the driveshaft I've got is not the T5 driveshaft. I couldn't really find anything to tell me for sure, but maybe someone will be able to tell me here. Spline count is 22 unless I'm counting wrong: This part is pretty much self explanatory: Also, the tailshaft yoke (I think that's what this is called) has a collar that goes up and over it. Didn't get a picture but it looks like this: 2) Wiring harness has kind of thrown me for a loop. I'm pretty sure these weird connectors don't get used, but I'm not 100% on that: Also this strange one wire, not sure what it is: Not sure what this connector is for...: I'm pretty sure this is a coolant temp. sensor but I cannot find where it goes for the life of me: And I can't remember what the heck this thing is: On top of that, I have to figure out how the hell to get this external wastegate on. The stupid wastegate flange is in the way of the bolt holes so I can't fit nuts on them.