-

Posts

3916 -

Joined

-

Last visited

-

Days Won

6

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by cygnusx1

-

Den, I have a full set of 76 280Z bumpers with rubber in really nice shape sitting in the rafters of my garage. I hate to think of how much it's worth and I really wanted to keep them for originality but I may consider selling all the rubber and or the bumpers. The front bumper is like new. The rear had a rust hole which was filled and painted....not real nice. The rubbers are all in 9/10 condition the front right corner rubber has one small tear about 2" long that I glued and it virtually invisible. PM me if you want to discuss. Here they are before I removed them

-

I bought a new dodge coil pack for my EDIS-6 system. However, it has four pins in a row instead of the four in a box arrangement. The pins are arrange in a row like the Ford coil connector but when I check them with my OHMeter I get this. _ _ _ _ 1 2 + 3 It seems that the positive is on the third pin, because I get equal OHM readings from that pin to each of the other three. Does anyone have this style coilpack from Dodge/Chrysler (mid 90's v6 4.0liter) vintage? Can they confirm the wiring? Thanks, I know it's a long shot, but I can't find a pinout for the coil pack.

-

I went to visit Mike (Buzz) to see the progress he is making on the old '77 that my friends and I built in high school. Mike took this car under his wing about 8 years ago after it had been sitting in a dark garage in the Bronx for 15 years. The car has a jewel of a motor in it that was bored and blueprinted. It has custom cut Venolia pistons making about 11:1 compression. The cam is a Nissan sports cam of some variety with a peak power band around 7500rpms. Mike, has been cutting, welding, stripping, little by little over the past several years. It turned out that the front end was a little crunched in a prior hit so Mike straightened it all out, replaced the crossmember, and fully restored the engine bay. The engine bay, fenders, roof, doors, hatch, and tail panel are all prepped already. The engine bay was his first paint job which came out awesome. Any day now the rest of the car is going to the spray booth, but first he has to weld in the Bad Dog rails. Check out the Ferrari seats we put in way back in High School. You don't hear many cars with an idle lope like that anymore!!!

-

Yes, sorry forgot that I switched to a 280Z balancer. The screws go into the v-groove flange near the bottom where it's thickest. They dont stick into the belt groove though. The screws were tightened and then I used a hacksaw to cut them flush to the inside of the v-groove. I then took the screws out and filed the ends flat.

-

Well, after many days of trying to string together a few hours here and there, I finally made some progress. What a PITA this was to do. First, the machinist made the bracket I designed, wrong. He was away for the weekend and I didn't want to wait for him so I fixed it, sort of, with a jigsaw. Ever "machine" 6061 aluminum 1.5" thick with a jigsaw? Anyhow it's better than a hacksaw. To locate the sensor, I needed to mount the wheel, BUT to mount the wheel I needed to know where the sensor was going to end up at TDC so I could align the proper tooth of the 36-1 wheel. Catch 22. I mocked up the sensor, then used double sided tape to stick the trigger wheel to the pulley on TDC. I then aligned the correct tooth with the sensor and marked the trigger wheel and pulley. I then clamped the trigger wheel to the pulley, centered it with a caliper and mallet. Scribed a circle where I could tap into some "meat", and drilled and tapped four 10-32 holes. Unfortunately, the timing pulley will not go on the front of the motor with the trigger wheel installed. It hits the back of the e-fan. Solution is to install the bare timing pulley and then screw on the trigger wheel with the 10-32 screws and some locktite. Anyhow....here it is. I still need to get the sensor bracket redone or reworked correctly. The bracket is very close to the A/C belt and the tail of the sensor is very close to the A/C clutch. It really sucks working on my back with my arms in a tight space between the radiator and timing cover with everything visually upside down...However, IT WILL WORK after much tweaking ...or it BETTER WORK! I used the DIY Autotune 6.75" trigger wheel. A smaller wheel would have been much easier because there would be more space for the sensor.

-

Yikes! I am going to get a close look at my filter tomorrow. The car is apart for a new head and EDIS so now is the perfect time to inspect it. Thanks for the heads up, but sorry you found out the hard way.

-

you get to drive a gt2 for a week...what's first?

cygnusx1 replied to 1 tuff z's topic in Non Tech Board

David, you are a family man....I can't tell you what to do with that car. -

My wife and I have retirement plans for 18 years or so down the road. We are going to ship our Z out to my family's apartment in Milan for a two or three month Alpine road tour. We will be sure to visit. Hopefully the dream stays alive.

-

http://www.morrisandwelford.com/currentoffers.html Audi Hillclimber Siata

-

A good wash will take it off. If there is any left, use a good cleaner/wax combo. To get it perfectly clean on top of all that, use a clay bar system. Then a final wax and polish.

-

Lucky you, my angry little bolt ended up in my U-joint in the steering column and locked up my steering wheel...while I was driving. Damn near killed myself and the car. Good find.

-

Very Nice!

-

(Sidebar about boost controllers for those that want to skip ahead.) There are two types of mechanical boost controllers. Ball-Spring and Bleed. Both of these are devices that modulate the pressure that goes to the wastegate actuator. The dawes valve will get you that low end boost. I believe the Dawe's is the Ball-Spring type which will get you that fat, low end boost by completely clamping the wasetgate shut until you reach target PSI. By clamping the wastegate shut the boost builds more quickly. I don't mean physically clamping. The Ball-Spring valve keeps any boost signal from getting to the wastegate actuator untill the boost lifts the ball off the seat. This allows the wastegate to blow open and bypass exhaust pressure to maintain setpoint. The wastegate is either Closed or Open, with very little modulation. The Bleed boost controller has a needle valve that you can adjust. It allows the wastegate to float open at anytime during the boost curve, as long as boost is over the spring pressure of the actuator. With it, you can modify the rate at which the gate opens to control the boost curve shape. The wastegate can modulated from Closed to Open, in a controlled manner, by turning the needle valve. MAXIMUM spooling is achieved with the wasegate shut, forcing all the gasses through the turbine. This does not necessarily equate to maximum power. Some engines might like NOT to blow through the turbine all of the time, and might make more power in certain RPM ranges with the wastegate partially open. There is no BEST solution. That's why you test and tune. Oh yeah...boost creep. Well, the wastegate is a port that lets the exhaust bypass the turbine to limit boost. If the port is too small for the amount of exhaust, it can't let enough out. What happens is that the excess gasses go back through the turbine and over-spool it. This builds boost in a runaway scenario which can be dangerous.

-

Hmmm...and I have my head off right now, the dremel is still warm from porting the intake and exhaust manifolds....my T3/TO4B SuperV is sitting right there on my downpipe, only four bolts away from being ported....and now you post this! Don't make me pull my turbo and port the wastegate..... How can I resist!

-

If I get it right, there will be no adustment in the bracket or the sensor. I am trying to get it "pinned" in the right spot. I am not going to tap the holes for the Ford sensor until I clamp it all up to it's final spot. I will then mark everything and fix it in place with dowels or shoulder screws. Once the sensor is in place, the 36-1 wheel will also be pinned to the front pulley. Being a machine designer, I learned that "no room for adjustment" is better than "room for wrong adjustment". Of course, if I don't get it exactly correct...there is always the hand file!

-

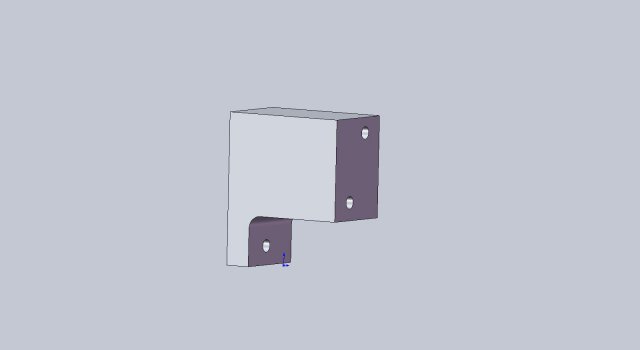

Stay tuned. I mocked up the 6" trigger wheel from DIY on the Z two-row pulley and measured up for the VR bracket using the AC bracket boss. The VR Bracket is shaping up to be very simple. Here is a rendering of the initial prototype. I will post it with dimensions when complete.

-

There you have it. I could no longer resist the urge to port. Not sure if I did any good or bad but I fit the gasket to the head and checked the port alignments. Marked the gasket in a couple of spots that needed trimming. Trimmed it, flipped it onto the intake all while centering the stud holes to the gasket. I decided to split the difference and hog out about half of the step. Here is a photo showing two runners left to do and one of the ones completed.

-

I would lean towards the pivot from what I have read here at HBZ. I even heard that it's not a huge deal if the wipe pattern runs right to the edge of the pad on the pivot side. It actually increases your rocker ratio, leading to more lift if that's what you want. Mine are slightly off center towards the pivot arm. I was able to carefully file down a factory shim by hand to get the wipe pattern where I wanted. Not sure if it's going to hold up because the head is still on my bench. I suspect it will be fine.

-

If you want the ultimate look, cut out about 6" into the roof line, weld it to the top of the doors and go "Gull Wing". I think Gull Wing is the sexiest and most useful door mod. I have never seen it on a Z. Go for it!

-

DIY front end alignments. All you need is a friend, a tape measure, a couple of wrenches, and a few test drives.

-

Very classy looking gauges.

-

I bet there is about 1/16" slop.

-

It most likely is to avoid tolerance stepping in the wrong direction. Nissan really went out of the ball park with almost 1/16" all the way around. Although, it is two casting processes with no post corrective machining, so I suppose 1/16" isn't that big a target. I bet beveling it up like B, and getting a perfect alignment wouldn't yield much gains anyhow unless the entire manifold was ported up to match. It's just so tempting to dremel it that I might anyhow. I have no way to quantify the gains or losses but at least I'll feel like I tried something.

-

bad ignition module or coilpack?

-

OK thanks Ron for the words of wisdom. It's just so tempting to grind anything I can find when I have my dremel in hand. I will resist the urge, stick to the basics, and the tried and true.