-

Posts

3916 -

Joined

-

Last visited

-

Days Won

6

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by cygnusx1

-

(AZC) Brake Shimmy When Warm

cygnusx1 replied to cygnusx1's topic in Brakes, Wheels, Suspension and Chassis

Funny you said that.... I took off the rotor and checked the hats from the inside, where the rotor bolt circle is, and it was off by around 0.008". For some reason I was reading dead straight on the outside of the hat with the rotor in place. Once the rotor was off I did the insied of the hat. So I decided to shim the four bolts that hold the hat to the hub. I added precision stainless steel shims that I had bought and got the hat to within 2.5 thousandts. Then I mounted the new rotor and it was within 0.003". I am going to do the other side like this, drive it, and then have them lightly cut after a few heat cycles. Verdict: Either the hat is warped from AZC which I doubt, the Z hub is off ( I didnt check it but I doubt it ), or the four hat bolts, when tightened, warp the hat. The hat has waves in it once bolted. I think the four bolt circle is just not enough to keep the hat flat. The rotor should "ride" over and smooth the waves anyhow. NOTE: The hat fits kind of snug around the hub center and there are fillets that could possibly interfere causing the hat to NOT seat flat on the hub flange. When I first installed this kit, I filed a bit of extra room into the hats for fillets that are cast into the Z hubs. -

(AZC) Brake Shimmy When Warm

cygnusx1 replied to cygnusx1's topic in Brakes, Wheels, Suspension and Chassis

I bolted on one new rotor from Wilwood and indicated it. It is off by about 0.015"! They claim flat and straight to 0.001 on the website so it must be warping when I tighten the 8 bolts to the hat. The hat indicated flat on the outside. I am going to see if the rotor is warped when I take it off the hat by laying a straight edge on it. I also have 0.001" and 0.002" thick shim washers that I can use to try to clock and shim the rotor straight. The whole thing seems strange. I am beginning to see the value of floating rotors. -

I think it...is....are....umm...fake...

-

(AZC) Brake Shimmy When Warm

cygnusx1 replied to cygnusx1's topic in Brakes, Wheels, Suspension and Chassis

I bought the replacements from pitstopusa.com as JT1 suggested but I didnt go for the more expensive GT48 series. I bought the direct replacement Wilwood HD Curved Vane series for $83 each. http://www.pitstopusa.com/detail.aspx?ID=71458 You need a left and a right one. -

(AZC) Brake Shimmy When Warm

cygnusx1 replied to cygnusx1's topic in Brakes, Wheels, Suspension and Chassis

OK so I took some late night time, went out to remove the front wheels to get the dial indicator on the rotors and hats. I already have the new rotors from Wilwood but I wanted to do some CSI work before I swapped them. The drivers side rotor is twisted by about 0.005" across it's face along a radian, at it's worse point. So runout at the outer edge is around 0.005" on both sides of the rotor, and runout at the base of the swept area is about 0.003". The passengers side rotor is out the same way but about 0.010" total at the outer swept area! I am sure these numbers get worse when the iron heats up. Both AZC hats are running within +/- 0.0005", while mounted on the hub, which is what I expect for a CNC machined aluminum part. So enough talk about pad material build up...it's a warped rotor. Period. On another note, I noticed that the passenger side pads are worn about 10% more than the drivers side pads. Maybe I need to open up and back flush my front brake lines and factory prop valve and splitter. -

I have an idea. Do you have another running car? Take the timing light to that car. Clip onto the #1 plug wire. Shine the light at the timing pulley towards the graduated marker and have someone start the car. Verify that the light works. This will also allow you to see what you are looking for on your Z. Sounds like you are getting closer. -Dave

-

notes: with a capital "W" too!

-

With stock injectors, and stock ECU I needed to run 65psi of fuel at 14psi boost. With stock fuel pressure and MS, you might be able to go over 10psi but watch out at the higher rev's when the fuel supply starts dwindling. My suggestion is to Datalog he AFRs at 10-11-12psi and keep it where you can rev to 5500rpm without leaning until you get larger injectors. Set your rev limiter before it gets lean by using the timing method.

-

She also says, "Take it easy, this car isn't glued to the road like an F1 car!"

-

I speak Italian. I can tell you that the funniest word she says is not a word. It's the phrase followed by the arm gesture that she makes at 1:46-1:48! LOL

-

I am a big fan of the Shuttle program. I grew up with it and will miss it when it's gone. Nice picture.

-

On the 280Z I am almost positive that they will adjust just by pumping the hand brake lever up and down several times. This only works if the shoe linkage and star adjusters are clean and well lubed. I remember a finger that acted as a lever to tweak the star wheel everytime the lever was pulled up. If the shoes are already tight to the drum, the finger just ratchets over the teeth of the star instead of turning it. Can anyone confirm this? Some cars use the reverse method but I think the 280Z uses the lever action.

-

Clive, post the original scan (full size) into your smugmug account which will automatically resize it into about 5 different resolutions. Then pick a larger one from smugmug and link the url here with image tags.

-

Clive, could you include some glasses I could download to read your chart? Better yet, stop by the house so I can test it with my butt dyno.

-

"Suicide or Lambo doors?" I would have to put suicide before lambo doors on a Z...ok where is my noose? :mrgreen:

-

When the WRX first came out...we saw the same thing in that community. Relatively, low dollar performance cars that a high school kids can twist out of their parent's wallet. All wheel drive get's you going really fast but stopping and turning is still done the old fashioned way.

-

Yes, that relay was pretty much already wired into the ZXT harness in the ZX it was all up by the battery/fusible link box. I triggered the relay from the IGN+ on the coil post (labeled new wire) but you can do that from any switched 12V source. The fuel pump relay in my diagram is not completely wired. If you notice, it's missing a switched 12v+. I don't know why I didn't document that. It was either already wired into the ZX harness or I missed it. I did use the ZX Fuel Pump Control Module initially. Eventually, the Walbro Pump killed the ZX Module and I just used a switched 12V+ to turn on the fuel pump. This is not ideal because if the car wrecks, the pump will keep pumping fuel. I think the AFM has a switch in it to shut the fuel pump off if the flapper shuts (engine off). My memory is getting dimmer. I did take some photos so look around at the photos. http://dcerutti.smugmug.com/gallery/1749234_5BA2m#87164467_Y92Cy

-

Where is that crappy diagram I made while I was upside down under the dashboard with my right hand using a left handed pencil? http://album.hybridz.org/data/500/TurboZ-WiringDiagram-DRAFT-1.jpg Not sure if it's ANY help at all but even if it gives you ONE little tiny bit of insight, it was worth posting.

-

I know I put down 265HP on a dyno once, so I just bought the G-Tech to back calculate the weight of my car. J/K it is a fun toy. Another excuse to go out to the garage turn a wrench and step on the right pedal.

-

Weird Idle, RICH spikes. MAPdot threshold not working?(datalog)

cygnusx1 replied to cygnusx1's topic in MegaSquirt

It's actually only 1 or 2 degrees over max spec for the 83 280ZX turbo. -

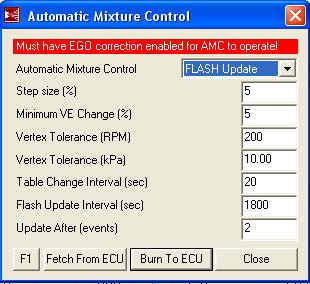

Well, I drove for an hour all over the place at different speeds and loads. When i came back from the ride and checked the old VE I had saved and the current VE which I saved before shutting off the car, and they were IDENTICAL! Hmm maybe I need to increase some O2 authority...or maybe my map is very close already. I did see a few EGO corrections in the 93% and 106% ranges during the drive but it didn't make any table changes. I suppose my parameters were too strict.

-

My bugeye shivers at the thought! Oh and I would miss the warm sound of the boxer sooo much.

-

You may use a universal relay. Just make sure the rated amps is high enough for the pump. I suggest something in the 30-40amp rating. Good autoparts stores should have universal relays and sockets for around 10-20 bucks.

-

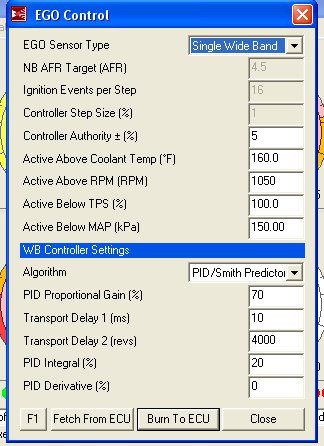

The megamanual seems to talk about SOME of the parameters that I can tweak in MT but for some reason I can't find information about others. I'm trying to do some fine tuning. Most of the coarse tuning is done, so I want to set it very "light" and just let it do it's thing running in closed-loop. for example: WB Controller Settings section, in the second attachment. I can't find info on those settings.---nevermind I found the section. Now I need to study.