-

Posts

250 -

Joined

-

Last visited

-

Days Won

18

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Invincibleextremes

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

Currently only planning on making 3 right now. I can make as many as people want really.- 282 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

Back in town and working on a couple cradles for a couple guys who want them here and now. Still waiting on the axle shafts. $255 per shaft if bought in bulk and they're made from scratch, and heat treated after. Got my hopes up, because these would be just the ticket to assemble on factory 2015 mustang cv axles. Mind you the factory axles use a hollow shaft on the left side... and these new ones don't. I'll post some pics soon of the cradles and hopefully have news on the shafts. Fingers crossed I'm dealing with good people... would be nice to have 500hp at 4,000 lbs capable cv axles for under $700 a pair... plan B is the $1,300 ones rated to 800hp at 4,000 lbs but thats a good bit more money.- 282 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

Just doing what i can. I should be back to work on it on the 25th, and I'm still waiting to see how the new batch of axle shafts turns out.- 282 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Cv axle options. or more so opinions..

Invincibleextremes replied to joa_taste's topic in Drivetrain

Thats literally what several different people are doing. Just not worth dealing with the factory stubs.- 7 replies

-

- cv adapters

- cv axle conversion

-

(and 3 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

Still away working, but before i left I was able to grab a pic of my old 240z stub axle compared to the 32 spline end of my 2015 mustang cv end. Definitely a night and day difference.- 282 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Cv axle options. or more so opinions..

Invincibleextremes replied to joa_taste's topic in Drivetrain

Its compatible... no matter what route you go, ditching the stub axles would be a good move. You can find whatever info you like on the super 8.8 swap I'm doing in its own thread so I'm not going to talk about that here. An option is to stick with the r200 and replace the outer uprights with either a techno toy tuning upright or one of your own design, or buy one from someone else. If using the t3 ones for example, you can rock 4 lug 240sx hubs and brakes and just figure out how exactly you're going to connect that cv joint to an inner that works with the r200... either via the 300zx axles and a hybrid 240sx shaft or maybe some porsche 930 race axle setup and finding off the shelf stubs for that application etc. 600 to 700 hp is up there however and hybrid 4 cyl car cv axles may not hold up very long. But the options are out there. Wilwood hubs used by race teams often use a tie wire method to keep things from coming apart.... so if dead set on using DSS axles maybe something like that is an option?- 7 replies

-

- cv adapters

- cv axle conversion

-

(and 3 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

Currently away travelling for work, but before i left, i mounted the setup again to measure axle movement and to see how everything works together and I'll be able to drive the car once i get back and plumb the brakes up. I do have a company making axle shafts from scratch through a member here. Heat treated new shafts instead of cut down junkyard cores. Hopefully those work out quality wise, and that will be the final piece of the puzzle...- 282 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

Assembled them. Planning on putting them in and seeing how short they are, or if they work. Working with another axle manufacturer to make a small batch that i can sell to who ever buys the mount... because i don't want anyone going through what i went through just to get a pair of shafts.- 282 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

I literally sent them a sample, and gave them written instructions that were a reflection of that sample. Plus i sent them both stars as well.- 282 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

Yeah I'll have to contact them for future batches.- 282 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

Got the axles back from moser. They're not as bad as the first set, and i can finally use them. But they are not the length I gave them and the shoulder on one side is completely wrong. I am now looking for another company for future orders, because there is no excuse for this. They wasted 4 weeks of my time to give me product that doesn't even come close to being correct.- 282 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

Plasma is "by hand" but stencils etc won't be hard to come up with. The axles I'm waiting on from Moser are STILL not here, due to weather delays. I'll be away for the next week and unable to touch the setup untill i get back. At that point i really hope i return to perfect axles from moser...- 282 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

Well, the good news is i have a 200 amp mig welder with shielding gas. And i now have a plasma cutter and im decent with it. I have located the last piece of the puzzle, the spindle sleeves and can now make as many or as few kits as i want or can sell. I'm no longer dependent on having to laser cut batches and have some parts be a minimum of 110 pieces. I'll see how far i get over the next few days on a kit or two and will post them for sale.- 282 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

Sliding sloppy splines aren't in the cards at all. The cv design on these axles uses an octipod... like a tripod but with 8 balls. And it takes up all the movement. The cv shaft was never supposed to move at all. But like you said i can always add another snap ring. The overall play is what concerns me. It'll wobble itself apart and sheer the splines in no time.- 282 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

Got my axles back from moser and they messed them up pretty bad. Now I'm out a couple of $35 cores and the money spent cutting them. I have contacted them and they told me to email them pictures and that they'll send it up and see what they'll do about it. The only right thing to do about it would be to refund me $70 for the cores, pay for shipping and cut me another pair of axles. But we shall see if thats what they'll do. I'm losing a lot of time on the back and forth regardless, but all I want is a proper pair of axles... The darker ones are the sample stubs i sent in, and the in white ones are the ones they cut wrong... even though they had a sample to compare to... all 4 ends are done wrong. The biggest problem is they cut the space between the splines too wide and the cv star or spider has a ton of slop in it... so simply cutting it for another snap ring on the back side won't fix it- 282 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

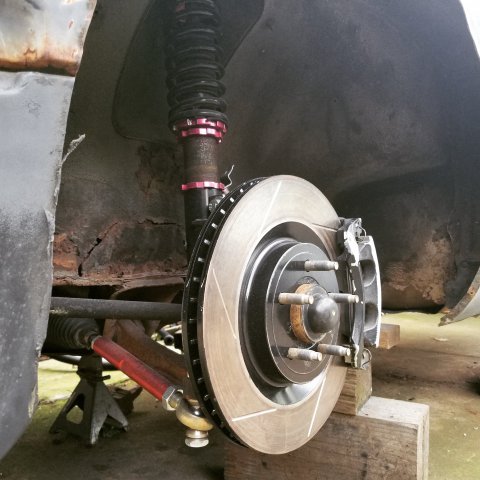

Mocked up the 2015 gt mustang rear brakes and they fit perfect on a datsun if you have the wheels for them. Might be a little tight with these 17 inch wheels but they're perfect in the wheel well. As a side note, i can still mount the 11.8 inch 2014 rear brakes to run a 15 inch wheel for drag racing. I'll just need a spacer at the mount points for the caliper for the offset to match. Can't beat the price. These are insanely large brakes... fronts 13.2 and rears will be 13.

- 91 replies

-

- suspension

- 240z

- (and 5 more)

-

ride height will be a little higher than this... but i lowered it to almost maximum, just absolutely slammed with large portions of my fenders cut out... And took a quick pic to show how much this setup corrects bump steer and roll center on very lowered 240z cars. Part of it has to do with the placement of the tie rod in relation to the ball joint, and the other part of it has to do with the spindle pin being 2 inches higher in relation to the ball join... Its essentially a drop spindle that has built in bumpsteer correction as well, especially when used with T3 tie rods.

- 91 replies

-

- suspension

- 240z

- (and 5 more)

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

Waiting on my axles to return. Meanwhile I'm finishing everything up and will be ready to drive it once the axles are back. Need to plumb up my wilwood pedals and maybe weld up some of the rust.- 282 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Once i re plumb all the brake lines and mount my new RHD pedal setup (and get my axles back) i should be able to finally drive it. While I'm here i need to address some of this terrible rust.

- 91 replies

-

- suspension

- 240z

- (and 5 more)

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

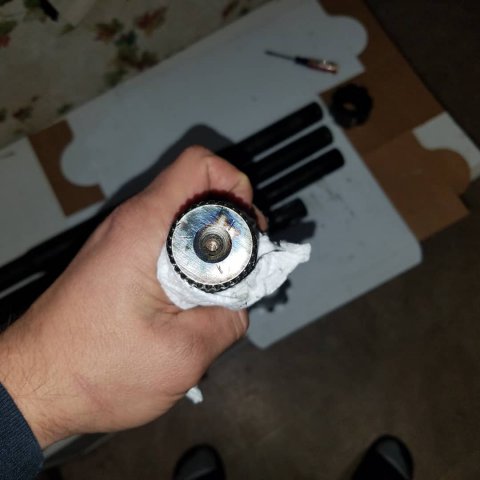

Went digging in the junkyard today. The hybrid cv joint idea is a no go, mustangs used 8 balls while the explorer (2004) used 6 balls. Would have saved me $125 by not having to spline both ends. But not a deal breaker. Still much cheaper than the 800hp axles, just not as cheap as I'd hoped. Here is a picture that shows why i picked these axles as cores. The shaft in the middle is the mustang one that i cut a section out of to make the perfect length.- 282 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

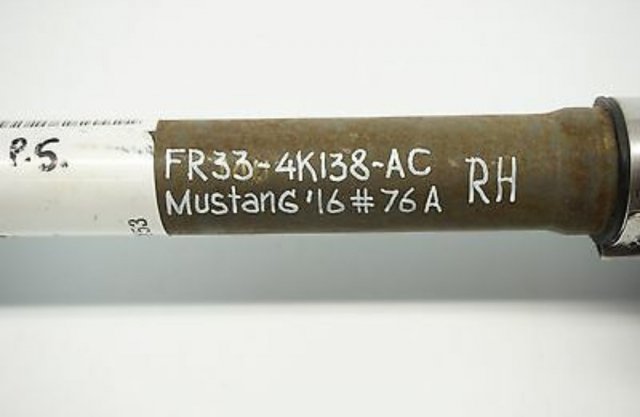

An example of what to avoid... the "AC" axles. It'll be on the tag, but this seller put it on the shaft as well.- 282 replies

-

- 1

-

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

Did some digging online. The left hand axle that ends with "BC" is for the v8. The one that ends in "ac" is for the weaker ecoboost. Ending in "38-BC" is right hand, and "39-BC" is left hand.- 282 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

Went digging in the junkyard today with the CV spider in my pocket. Turns out the 02 explorer has the same diameter shaft ends... but courser splines. The good news is its a solid heat treated shaft and its the same thickness its whole length, necking down only for the splines. I also called moser and talked to them about sending in a core shaft and paying for two pairs of CV axle spline service and they're happy to do it so long as they look everything over and it seams like it works. Cutting the heat treating off the hollow shafts just wasn't sitting well with me. I also discovered that the two left shafts are different on the ends in diameter and one had a slightly smaller cv joint pair... I'm guessing i got one v8 shaft and the other from a v6 car. Both are splined the same into the housing and at the hubs... but one is stronger than the other with bigger cv joints. The left and right v8 shaft have the same size cv joints... its just the spare left shaft had some differences. Going back to the junkyard tomorrow to compare my cv joint to the explorer outer cv. If they are the same internally i plan on building a hybrid cv. But if they're different I'll pay for 2 pairs of spline service and know that I'll never have to worry about the strength of those shafts...- 282 replies

-

- 1

-

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

The $1,200/pair price tag isn't for shafts, its for the entire thing, 930 cv joints and all. With 34 spline stub axles into the housing and 32 spline stub going into the hub bearing. Totally agree with you on the smaller diameter full floater style shafts.- 282 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with:

-

Ford Super 8.8 irs swap thread. Rear brakes too

Invincibleextremes replied to Invincibleextremes's topic in Drivetrain

Cutting hollow axles isn't my first choice, but they're still head and shoulders better than what came in these cars. Ideally i would ship out some solid shafts taken from a junkyard for cheap And pay for the service of 4 ends to be splined... This would still be incredibly cheap but give me some peace of mind. The core axles themselves are 55 to 75 bucks per side. The end plan is to just shell out the $1,200 for some 800hp axles plus 100 for them to be in a custom length. This is still cheaper and stronger than anything offered before in a 240z. But right now what ill be testing is just how much abuse the least favored setup will take before i have to either get the shafts replaced with solid cores or buy custom made shafts. On monday I'll get all that figured out.- 282 replies

-

- disc brakes

- suspension

-

(and 7 more)

Tagged with: