-

Posts

725 -

Joined

-

Last visited

-

Days Won

8

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by FricFrac

-

MS3 w/ MS3X Install - L6 turbo, sequential injection & boost control

FricFrac replied to Sam280Z's topic in MegaSquirt

The manual gives you a default setting to get it in the ballpark.... -

Factory injectors are low impedance or 2.5ohms. IIRC the '81 has a current limiting resistor of around 11 ohms (?). If that's the case then you are drawing roughly 1 amp per injector so with three injectors you'll pull 3 amps (ish) per bank. With the MS you can run PWM and you don't need to run a resistor in series

-

Who'd be interested if we made a L28ET trigger wheel?

FricFrac replied to Matt Cramer's topic in MegaSquirt

You can run COP or CNP with the stock dizzy (just for the optical sensor of course) but only in wasted spark mode (eg you will fire the coils twice as often as needed) but you will need a new wheel if you want to run an EDIS style setup or distributorless. -

There are two different TPS for the S13. One has just the pig tail from the standard and the auto has the pig tail and the plug just like the S30/130 TPS (as in switch). Don't use the plug built into the TPS if you have the automatic version as it is just a switch.

-

280ZXT Test Mule not project project....

FricFrac replied to FricFrac's topic in S130 Series - 280ZX

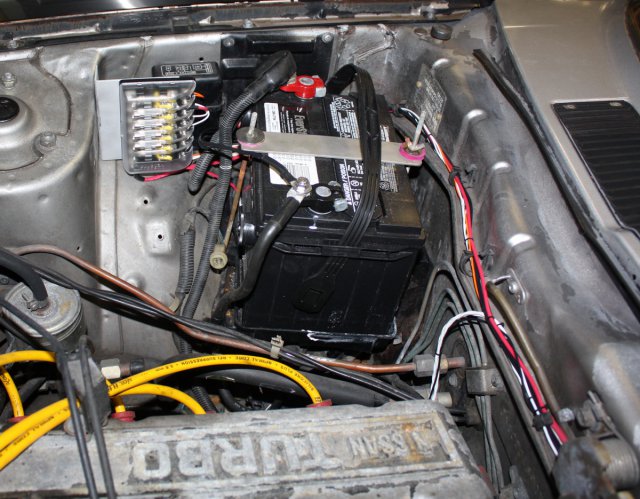

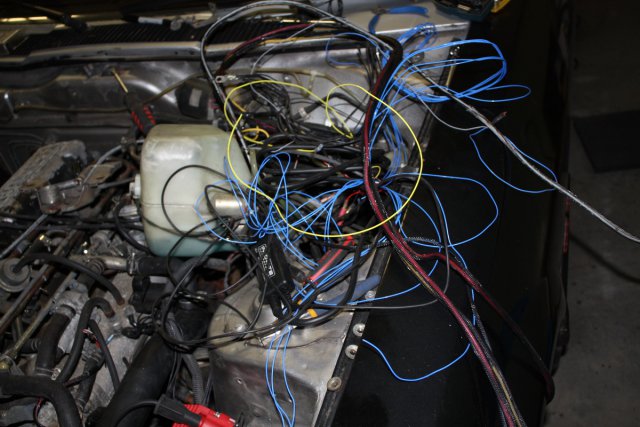

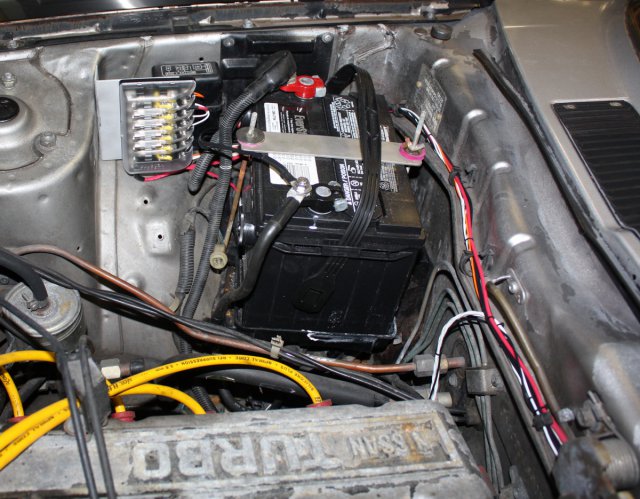

Wow I've put a ton of work into a little bundle of wires over the last two weeks but I've had some really great sucess with it all. The MS3 is running great! Went out for another test and tune today. Told my buddy that the car was running better than I've ever had it run but it felt like I needed new engine mounts as the engine was shaking a lot at idle. He kept saying it was like it had a dead miss. Anyhow we had stopped for coffee and were going to continue our run when we decided to pull the injector plugs one at a time. Pulled injector plug 6 - worse, injector 5 - worse, injector 4 - no change! Put it back on half way and it was smooooth.... arg corrosion on the injector - new injector plugs on the harness doesn't matter if the plugs on the injectors are corroded Wow the car is a new beast and I've only put on a cone filter, removed the AFM with a piece of pipe and a crush bent 3" exhaust all held together with the MS3. Pretty impressed how smooth and how much more power I've got by the butt dyno and no dyno tune either. Moral of the story is 6 is better than 5 on the L6.... who knew! Here are some picturesof the harness right up to the current running prototype. It all plugs into the stock body harness and fuseable link box so I didn't have to cut into the stock harness anywhere. Also the AFM delete, IAT on the J pipe (till I get the intercooler figured out), etc. -

Wiring nightmare, need help ASAP 83 NA to 83 Turbo Swap

FricFrac replied to Wangan280's topic in S130 Series - 280ZX

I'm not sure if the turbo ECU will drive a NA coil since the turbo uses an "ignitor" to fire the coil.... -

Wiring nightmare, need help ASAP 83 NA to 83 Turbo Swap

FricFrac replied to Wangan280's topic in S130 Series - 280ZX

Check to see if you can hear the fuel pump relay turn on (it's under the glove box). As VinhZXT stated the turbo has a fuel pump modulator which hooks up to the plug on the side of the harness inside the driver foot well about 10 inches back up the harness from the ECU. You'll need the FPM from the swap car or you can ground the black wire on the "T" shaped connector (power is green) between the rear pillars towards the passenger side. That bypasses the modulator so you can at least get the pump working. -

81 Datsun 510 station wagon tranny question

FricFrac replied to garretthes's topic in S130 Series - 280ZX

Do an S13 swap instead. They are much more plentiful and you should be able to get a low milage one cheaply. There are plenty of threads on the minor mods you need to do for the swap -

How much for the spoiler shipped to 98121?

-

MS3 w/ MS3X Install - L6 turbo, sequential injection & boost control

FricFrac replied to Sam280Z's topic in MegaSquirt

Did you try adjusting R52,56 on the main board and R11,32 on 3X? Could be you are on the hairy edge of them triggering.... -

I'm not trying to make a mass produced harness. I'm interested in making a high quality harness for people who are looking for a profesionally engineered and constructed harness with high noise immunity and professional fit and finish. Anyone can make a harness. I can spec up a harness and have them manufactured and make a decent profit depending on demand. I have the contacts for fabrication, etc but it has little interest to me. I'm doing this in my free time so it has to be something interesting to me.

-

Totally normal - he's super busy and this is something he does as a courtousy to HybridZ. You don't normally deal with the manufacture directly but you are with Kim. I'm surprised we even have this setup and it's still going. I just wish they had another option for wheels in this offset and sizing.

-

Alas Wednesday is Soccer night apparently.... or apparently I forgot about it although my wife almost sent me to the wrong field. I really did need to do a few more things in the harness for the Wideband O2 power, etc. We have a Datsun club meeting tonight but I'm that close to testing it out. I'm hoping to get the insurance pulled off the 370Z and insure the 280ZXT tomorow or this weekend

-

Who'd be interested if we made a L28ET trigger wheel?

FricFrac replied to Matt Cramer's topic in MegaSquirt

Just for reference sake Pin 32 is on the MS3X board not the main board.... -

I've also been using iDisplay to use my phone as a second monitor so I can display from my laptop the gauges on my phone

-

Just curious if anyone has ever had a single bank go out (fuse, IGBT, etc) and limp home in that mode. I mean it sounds like a good idea but has it ever saved anyone's bacon? Just idol curiosity. You could do the exact same thing by disconnecting a single bank and putting the fuse back in - you have a 50/50 chance of getting it right if not put in a second fuse and you would be able to limp home anyhow....

-

Lol my first victim.... er client.... Don't worry bro you can't get me any more motivated on this than I am The first harness is coming along nicely and I've made a few tweeks on this harness MAYBE even fire it up tonight. Once I have that done I'll start laying yours down then I can finish building your MSIII. Closer and closer....

-

There are some portions of the harness that will be the same or very similar but the idea is to build the harness to the customer's specific need. Each harness will be hand crafted and built to the requirements of the end user. There isn't really any significant time or cost savings to making a bunch of generic harnesses although many will be very similar.

-

Cheap is a relative thing. These are cheap if you consider the labour or the cost of similar products. They aren't cheap if you are expecting to get a harness for $100. I figure once I've got a system setup there will still be 20 to 30 hours labour to build them plus the cost of materials. I intend on keeping the cost lower than most custom harnesses which range from $700 - $1500 and up. It's unlikely that I will build a "cheap" version using lower cost cabling, etc. If I'm going to design and fabricate this I want it to be up to my standards - design, materials and fit and finish. Expect the entire kit to run around $550 which doesn't actually cover my labour cost.

-

280ZXT Test Mule not project project....

FricFrac replied to FricFrac's topic in S130 Series - 280ZX

Yea I contacted Jeff about it but he didn't have any left and he said it was such a nightmare he wasn't planning on doing another run. Oh well I'll just have to find another way -

The stock engine harness is basically garbage. I have yet to see an original one where the shielding on the Dizzy side is still in good condition but given that it's exposed to the elements it's not fair to expect it too be. There is basically no shielding on anything other than the O2, the fuel pump control (don't care with MS) and the dizzy. An auto engine bay is full of EMI that can cause problems with any electronic fuel injection system. Look at a 240SX wiring diagram and you'll see that the manufacture shields almost all of the sensors. I've been researching a few other after market engine harnesses for other engines to see what the other guys have. The 2JZ, etc have a lot of after market stuff and they boast Raychem this and MIL spec that but only bits and pieces are they way they should be. I've seen a lot of "quality" harnesses that boast MIL spec and yet the sensor signals travel over a single vinyl coated wire. So again out of frustration we are left to do it ourselves. Fortunately this is my area of expertise and I'm currently developing a EMI hardened engine harness for the S130 and will be designing one for the S30 chassis. The basic design will allow for a plug and play to the stock body harness (on the S130 at this point in time - haven't done my homework on the S30 yet) to control the stock fuel pump relay and fuel pump circuit (the S30 harness will have it's own fuel pump control). It will have its own fuse system and relays. The main intent is performance first (EMI hardened and the highest quality cabling, etc) and asthetics as an important secondary. You should be able to pull out your stock S130 harness and plug this harness in with an excellent fit and finish. If you ever want to go back to a stock setup simply unplug the aftermarket and plug in the new harness - no cutting into anything. Currently the design has all sensors shielded and cabling for your Wideband 02 with fused power and shielded input. The knock sensor and CHTS are not used with MS3 but are included (shielded of course) in the harness should you wish to use them. There is the capability to unplug the injectors from a built in adapter to go from batch fire to plug directly into the 3X board for sequential injection. An optional crank fire or disrtibutorless ignition harness is also being developed. Since each configuration may have slight variances as to where sensors are located each harness can be built for the particular application. Working on a custom car can be frustrating under normal circumstances but trying to chase electronic gremlins can be a nightmare even for an Electronics Engineer. The purpose here is to have a harness that starts you off from a solid base so you aren't chasing your tail and you can concentrate on the rest of the design of your car. Let me know what you guys think and what you would like to see from a properly engineered quality custom harness.