-

Posts

725 -

Joined

-

Last visited

-

Days Won

8

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by FricFrac

-

First of all you're going to have to figure out how much you want to spend because you don't really know what you want. You just know what you think you would like in a vauge general kind of way. Once you know how much you can spend then you need to start to figure out how you are going to implement it. Reliable is built into these cars for the most part aside from rust. Making an L6 sound phenomenal is really personal preference thing - listen to some YouTube videos and see what you like. Post some pictures of the car and do a LOT of reading here - I spent over a year researching before I decided to go with an L28ET swap in my NA. Read the forum rules and follow them - especially about researching because almost any question you have will already have been answered here. Welcome to the club!

-

Thanks for the reply Ross. Glad the video helps! Like I said I was kind of embarased forgetting to put the seals on the wire before I crimped them on but I left it in the video as it's a good reminder to everyone watching make sure everything is in place before you crimp/solder you pins on. Maybe that will save a few people from making the mistake

-

Are you getting voltage to the coil?

-

Ok I made a little video up to give you some pointers on repairing your wiring harness. I did the AFM which is the most complicated of the ones we'll be replacing. It's a little embarasing because I messed up the connector trying to keep the video time short but I left it in. It's a good reminder to make sure you've got everything in place before you solder or crimp your connector on. I do this sort of work all the time and I should know better - shows you what happens when you rush Anyhow if you have any questions the video doesn't answer feel free to ask!

-

I suppose it's all relative. Basically you chop off the old and crimp/solder on the new then slide the pins and connectors into the sockets and you're done. I'll do a video with a few pointers on how to change them and if people want pigtails I can do that as well for a moderate fee. With pigtails you chop off the connector and connect the two wires together and solder them. It really depends on your soldering skills. Soldering is pretty easy to learn and after an hour of practicing you should be able to solder pretty well. There are a ton of tutorials on soldering and it's a good skill to have that doesn't require a lot of practice to be practical at anything you would normally solder with your vehicle.

-

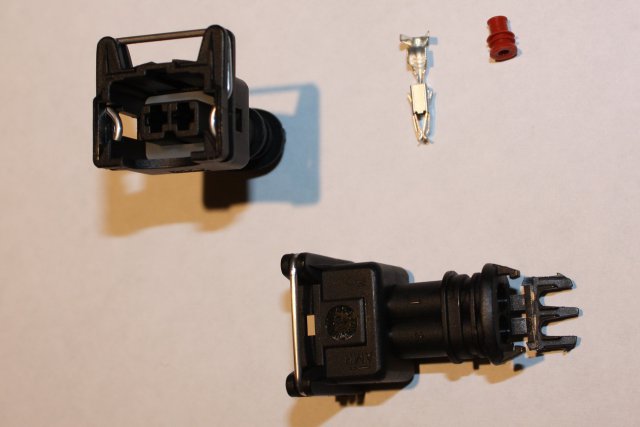

Yay the connectors are in! Well sort of... they sent me the wrong TPS connector which apparently is on it's way - grrrrr. Anyhow I'm super happy with the connectors - they are actually better than I thought. They are better than the stock connectors in a few different ways. First they have a silicone gasket inside the connector to keep water out. They also use a silicone plug on the wire going into the connector to keep water from getting in on the wire side. They also have a squeeze release mechanisim so you don't have to mess around with the clip to get the connector to release. You also don't need to worry about loosing the clip! The AFM also has a rubber boot similar to the original stock one. The pins are also a lot nicer than the stock pins. They have a secondary spring which helps increase the clamping force on the terminal giving you a better contact and less chance of having an intermittant fault. I found the connectors Ross Man pictured but they were more expesive and didn't seem to have any features that these EV1s don't have (eg water proof, squeeze release).

-

Get ITM pistons. They are hyperutectic, come with rings and wrist pins and a very close to each other in weight and they are only about $35 a piston!

-

I'm not sure how you missed the normal assault that comes with asking this question which has already been asked and answered 2.486 billion times on this forum. Consider yourself one of the lucky few and use the search feature to get way more information on the topic than you'd ever care to know. There is a TON of information on this topic and people on here tend to get a bit testy about people joining up and not following the rules on the forum (go back and read them and you'll know what I'm talking about.)

-

I've managed to source connectors for the stock engine wiring harness for the early FI S30 and S130 cars. I'm just posting here to see if anyone else would be interested in a kit and I'll order in some extras. The kit will include nine EV1 connectors for the fuel injectors, cold start valve, idle air and thermal switch, a three pin connector for the TPS and the seven pin AFM connector. I'm redoing all the connectors on all my harnesses and I ordered in extra connectors for a few members on the forum who requested a kit. Price will be $50 shipped in US/Canada. There is well over $100 worth of connectors so this is a great deal. If you have a 280Z, 280ZX or engine swap EFI and you haven't replaced the 30+ year old connectors on your car yet you need this kit! A lot of the problems on the car have to do with corroded or loose connectors. Cleaning the male side of the plugs is possible on the AFM, injectors, TPS, etc however cleaning the female side on the connector is difficult and doesn't often last. The reason is that the male connector is easily accessable and are usually solid brass. These can be cleaned/polished to new condition. The connector side is plated and the disimilar metals cause corrosion and the plating is destroyed in the process. Cleaning the corrosion is difficult because they are physically difficult to access and with the plated material missing the base material will quickly corrode and the problems will come back. A lot of the problems associated with the idle and running of the car are associated with the AFM connector. Often the clip from the connector is missing causing poor a poor connection which can cause intermittant faults which are often difficult to track down. The replacement AFM connector includes the new body and clip as well as new pins to get rid of the many problems this connection causes. I would also highly recomend replacing the stock negative battery cable with a heavy cable to the starter and one to the chassis. I also recomend a ground cable from the chassis where the battery cable mounts to the ECU and from the ECU to the ground point for all the sensors on the manifold near the Idle air valve. Replace all the connectors with this kit and you have an excellent base for your electronic fuel injection system. Replacing your connectors isn't going to solve all your electrical problems but it will give you a good solid base and eliminate a lot of potential problems and prevent future problems.

-

'83 280zx Digital Speedo Cluster/Harness questions

FricFrac replied to rforrest's topic in S130 Series - 280ZX

Just to clarify for others referencing this thread you don't need to swap the fuel sender or temp sensors to convert from digital to analog -

Updates?

-

Why wouldn't you run it through the MS3? The MS driver is more than capable of driving a stock 280ZXT coil and even if the coil is a dead short it has built in protection to shut itself down. The only thing you need to do is make sure you have your output set up as inverted like all the documents say.

-

I'm assuming you've already tested your MS or you bought it prebuilt. If you are building it part of the build is to confirm some test points along the way. Once you've tested the MS with your stimulator and install it in the car all I hooked up was power and verified it was working OK. After that I hooked up everything else except for the ignition and injectors. Once I had everything calibrated I hooked up the ignition system and tested for spark with the output test mode. ONce I had spark tested I hooked everything up and tried to fire up the system. I did have a problem before I hooked up the ignition system. I'm running off the stock harness with an adapter I built for my S130. When I turned the ignition on the fuel pump wasn't coming on. Checking the schematics I saw that the stock ECU sends +12V to the fuel pump relay coil which is grounded on the other side - MS turns ground on so I was putting ground on both sides of the relay coil. Made a little relay in my adapter harness that takes the GND signal from the MS and outputs 12V to the relay and up she came.

-

I doubt it. You could drive a logic level IGBT or FET to drive the input to the MSD. Why not use the stock spark output?

-

I'm running basically a stock 280ZXT my only changes are a cone filter still running through the stock AFM (using the air temp sensor through the stock harness) and a crush bent 3" exhaust no cat stock downpipe. I have a MSD SS Blaster coil driven by MS. I've got a solid idle using the set screw on the stock TB to adjust to about 800 RPM. Advance is set a 19 degrees in the idle portion of the map. AFR is around 14.0 Req Fuel is 11.6, 2 squirts per cycle and none of the plugs are indexed (manufactures recomended NGK turbo). I ran VE Analyze Live! and it has the VE around 44 or so and did help smooth idle a bit.

-

My 560ZX ( Titan VK56DE powered 280ZX S130 ) Build Thread

FricFrac replied to Jared's topic in Other V8Z Tech Board

Very nice - keep up posted. Any idea of the weight difference from stock? -

Sounds cheaper to find another L28ET that isn't destroyed.... and if you are going to replace the cam why not go with the "A" grind? You could get a stock NA block for cheap or free and use all the bits from there - only the oil pan and pistons are different. You can get really nice ITM hypereutectic pistons for about $35 each with rings and wrist pins. You can spend a lot of money fast and get nowhere pretty easy the way you're talking. I wouldn't be surprised if you found a new crank that cost the same as buying another L28ET. If you want to rebuild - ITM pistons, hone the cylinders, ARP head and rod bolts, clevite crank and rod bearings, gasket set and have the machinist resize the rod ends. That will give you the best bang for your buck on the bottom end. Port the intake manifold.... ah I'm just saying what's been said a hundred different ways ten thousand times before here..... but you get the idea.

-

-

You should consider going with a MegaSquirt setup. You can get rid of a lot of older vaccum activated/controlled stuff and have MS controll idle air, etc. You won't need the cold start valve either since MS has a fuel enrichment that just uses the stock injectors, etc. It's worth checking out and its a much more functional/expandable/configurable, etc, etc system plus you can tune the car, etc, etc..... the list really does go on and on. I'm recomending it before you spend the money to fix stuff that MS can eliminate or fix for you....

-

Mine didn't follow the AFR until I turned the EGO Sensor Type to Wideband - opps I also noticed my AFR reading in TS is about .5 off from the gauge..... and I also forgot about the bright blue lettering below the setting for the EGO that says "Remember to Calibrate and set Project Properties"..... doh! Calibrate sensor helps as well....

-

http://www.mandrel-bends.com/catalog/mandrel-bends-34/409-stainless-steel-14-gauge-74/3-00-stainless-steel-409-4-00-radius-180-degree-mandrel-bend-1012.html 4" bend radius gives you the extra room if you need it... like on the S130 with the firewall, etc...

-

10 degree at idle for the NA and 20 for the turbo