NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Coilover oops - need to raise rear - help?

NewZed replied to traininvain's topic in Brakes, Wheels, Suspension and Chassis

The stock springs are preloaded. That's one of those areas of suspension that isn't often discussed. Ideally, ride height, preload, and spring rate all converge. More preload gives a stiffer ride over the small bumps, I believe. Something to remember if ride has problems. Not a suspension expert. I thought Prime might be involved. Oh well. Looks promising, your pictures came up full-size, pretty quickly. -

It will run on the lower CR, it's been onde. Just thought you should know. You saw my post on other possible effects though, right? If the head's corroded, other parts might be also. Corrosion is usually from running water without antifreeze.

-

Nietzsche's unquoted works....

-

P90 and N47 have different size combustion chambers. N47 gives a higher CR than P90. In case you were looking for a direct swap. P90 on dished pistons is the turbo CR. P90 on flat tops is stock. N47 on flat-tops is "performance".

-

Photobucket links take you off the forum to another web site. If you Attach the files, they get saved on the Hybridz server and become part of the post., I think. Attached a couple to see..

-

Coilover oops - need to raise rear - help?

NewZed replied to traininvain's topic in Brakes, Wheels, Suspension and Chassis

Second the 280Z insulators. A common "fix" to raise the car, or vice versa with 240Z insulators. What is this Amazon Cloud Drive thing that you posted your pictures from from? I clicked it even though it was going to try to sell me something. Looks like a Photobucket type thing? But much faster than Photobucket. Does it cost something? -

It's been described here and there. Some guys use a press, some use an air hammer, I believe. And a big oven, sometimes. Seems like an easy job to do in principle, and an easy job to screw up in practice.

-

Wow, that's pretty cool. You could try borini63, 88dangerdan, or zentech by message. They all sell parts. I think that borini63 might be in your neighborhood. That's a lot of corrosion though. Makes you wonder about the block also, like the core plugs. They're thin.

-

My mistake. I thought there was more space between the block casting and the plate. Could be that you have two leaks. The stuff in the transmission might be gear oil, leaking from the front cover seal.

-

If the rear seal is leaking the crankshaft could be throwing oil all over that area between the plate and the block. From there it can follow many paths. Remove the plate and take a picture of that area. That might be more informative than oil in the transmission bell.

-

It's not combustion that's the issue, but fuel quantity available per cycle. Not often thought of as "fuel" but oxygen is part of the equation. With good engine management, less oxygen used means less gasoline used. Of course, that's what turbos are for, so it may be moot. Depends on boost level, I'd guess.

-

When things jam and break and the broken pieces then jam between other parts, damage can be subtle and hard to see. Looks like you'll need more than just a $250 rebuild kit by the time you're done. Good luck. I'm interested in how much it ends up costing and how well it works when it's done. I'm no expert. It just seems like you could find a working used transmission and get it rebuilt, and be ahead when it's over. Yours look like it needs to be repaired by an experienced professional. I wouldn't take it a shop that will just install the parts from a rebuild kit. Start a thread on rebuilding T5's, with those pictures, and you might get some good input.

-

There's more to good transmission operation than just synchros. The teeth on the gear itself, for example. The teeth on the coupling sleeve. They're on the inside. Proper alignment of the shafts. Proper alignment of the gears. Shift fork wear. Synchro replacement makes slightly worn transmissions work like new if you get there in time. You are way late. The odds are against you.

-

A few more things, that get overlooked but could explain why some get high mileage and some not so high. Altitude. Higher tends to give better mileage, in my experience. I lived at 5,000 feet for a year, and 300 feet for four, with the same car. But if you try to find supporting words on the internet you'll get way lost in numerous bizzare explanations of what happens at high altitude. The most general explanation is that high altitude air is at lower pressure (fewer air molecules per unit of volume) which means less air enters the engine for each cycle. So, basically, the engine is effectively smaller and creates less power. Power comes from fuel. Do a Google if you want to be entertained though. Engine temperature. Hotter tends to give better mileage. Probably for a combination of reasons. Again, the Google will entertain. Thermodynamics and engine theory is hard. Air temperature - summer vs. winter. I've had my car long enough to see ~18 mpg in the winter, and 20-21 in the summer, consistently. 1978 engine, 1976 system, no EGR, essentially stock. This might just be from the fuel maps in the stock NA ECU. But 1987 is still fairly primitive. Could be a combination of air and engine temperature, but my cooling system seems to do its job well. Seems mostly air. One other thing I wondered about, that I've seen overlooked in these swaps, is the wire cleaning step for the MAF. They can get dirty. Don't know much about it though.

-

Is the driver's and passenger seat interchangeable?

NewZed replied to dpuma8's topic in S30 Series - 240z, 260z, 280z

Pretty sure that I mixed backs and seats and sides when I pieced together a good set for my car. I think that you just have to take more parts off if you're having problems. You'll end up with just a cushion with some holes in the sides and bottoms. Rebuild from there. -

About $160 at the wrecking yard. Which probably has a 30 day warranty. Keep swapping until you find a winner. http://www.picknpull.com/part_pricing.aspx?LocationID=77&Language=English&NavItem=12&SearchCriteria=partpricing If you can test drive it that adds value. 3rd gear is usually the bad synchro. They all shift well at low RPM, it's up high where problems are. Shift lever rattle doesn't tell much.

-

Anywhere between the fuel filter (a sizable pressure drop from the pump pressure) and the carbs would be fine. You want the gauge to show the pressure that the carbs see. That's what you're trying to monitor and control. Carburetor fuel bowl pressure.

-

The engine management system is designed for a certain flow rate. http://www.fuelinjector.citymaker.com/Fuel_Injector_Flow_Rates.html http://www.rceng.com/technical.aspx

-

bradyzq makes a good point. The ECI control conditions are described in the usual place, including O2.

-

I'm just going through the basics. Seems like you have them covered. I'd separate the stuff that affects cruising mileage from things that don't. Like "running 12psi intercooled" doesn't have much to do with cruising at 70 / 2600 RPM. Then there are the basic tuneup items, like valve lash and ignition (clean plugs, no misfires, etc.). That's about all I have. Sleeper is the standard, maybe he's got something.

-

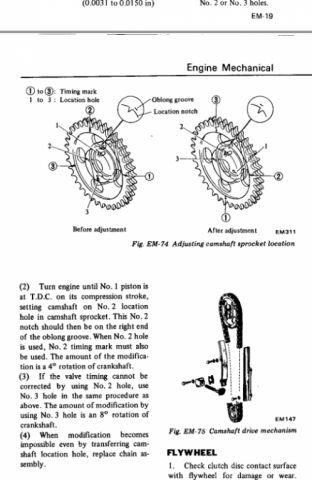

All that matters is the relation of the camshaft to the crankshaft with the straight side (driver's side) of the chain straight and tight. The chain links just end up where ever once things start rotating. The bright links are just a convenience for chain installation. The effect of cam timing on power is well-documented all over the internet. What's probably going on is that the guy you bought the engine from moved the sprocket to #3 to get more low end. You probably have a race cam that will never work well at low RPM. Or there's something else not right and you're just focused on the wrong thing. What's your ignition timing set at and what's the advance curve of the distributor? Is it working right? Carbs or EFI? Cam timing doesn't seem like the source of the problem. http://www.compcams.com/Pages/413/cam-timing-lobe-separation-angle.aspx

-

So this is an aftermarket cam. You should set it up the way the manufacturer recommends. Although most cam shops use the stock factory marks. So the notch and groove are still relevant. Also, your thinking seems to be backward. Advancing cam timing moves the power curve to lower RPM. You said that you should have more power at low RPM, "no power below 5k". So you're going the wrong way to get more low end. Nissan set the holes up so that each higher number advances cam timing to make up for chain stretch. You're already maxed out to get more low end. If the head was off the engine, you could put a wrench on the sprocket bolt and spin the cam pretty easily, with all valves and springs installed. You're probably just being too careful. BUT, you're still missing the point about the holes only being 4 crankshaft degrees apart. That's only 2 camshaft degrees. You already have 10 degrees of movement. Why are you trying to rotate it farther? You should stop what you're trying to do and study up. You're wasting your time.

-

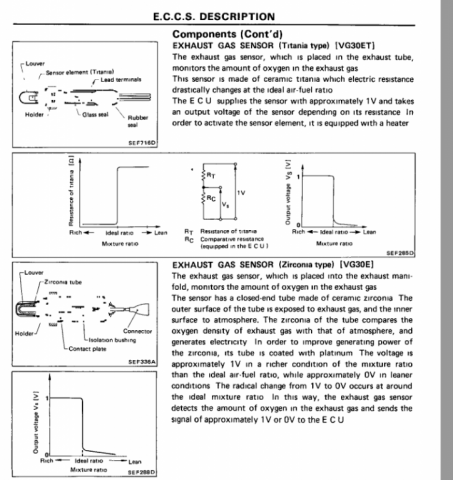

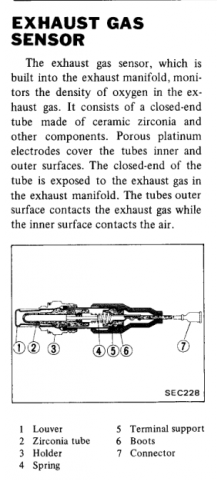

The O2 sensor still seems like the place to focus. Are you using the one for the L28ET, the VG30E, or the VG30ET? The VG30ET ECU expects a different type than the other two. Just asking. I never really know what people mean when they say they "did the test and it passed".

-

Posts that begin with "sigh" are almost always irritating to read. It's so hard being superior... Just realized I'd seen that "sigh" before . Six Shooter is the only guy that knows how to tune a GM Engine Management system correctly. It's easy. Or rather, it would have been if he'd finished. Weird how things repeat.