NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

So what is the relation of the notch to the groove then? If the engine runs why would you pull the head? The logic train has no tracks...

-

Define freely. The shiny mark only matters during the first installation. Once the engine turns it will only line up occasionally. The notch and groove are what you use on a complete engine that has been turned. Seems like you're not really sure how things work, be careful. Read the Engine Mechanical chapter to learn about the notch and groove. Study the valve train parts to see how the parts work together. The springs close the valves and the cam lobes open them, against spring pressure. So of course the springs will resist. But there are also springs trying to close valves that are already open. It's a wash. If you can only move the cam shaft +/- 10 degrees, something's more wrong than cam timing. But you shouldn't need to move it that far anyway to switch holes on the cam sprocket. You're going to bend a valve if the head is installed. Did the engine rotate before you decided the cam sprocket needed moving? Edit - just realized, considering all, that odds are high the problem is bent valves. Might be too late for cam timing adjustment.

-

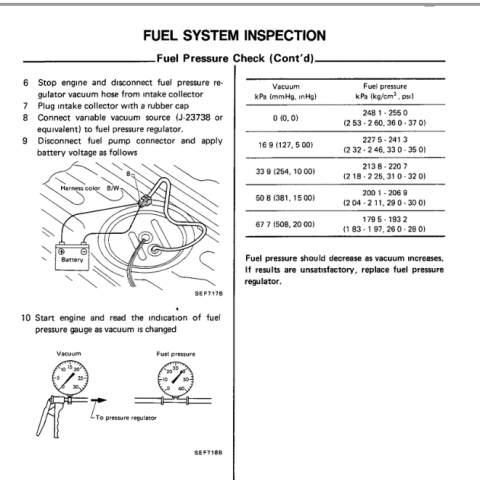

It's a start. A few observations: - 36 psi at 19 inches of vacuum is too high. Maybe you were reporting two separate things. Added a chart from the 1984 FSM. 36 is about right with the vacuum line to the FPR removed. - there are six years of Z31. Which year do you have? - You can check your odometer via mile markers on the freeway at any speed. - Extra resistance can make a difference on the CHTS circuit. "Functioning correctly" is not the same as optimized for efficiency. Always good to check the chart. Just some small things that might add up. There's also a test procedure for verifying that the O2 sensor is working right. I don't know how bad the sensor has to get before you get a code, with the early ECU's. Later ECU's like my 95 Pathfinder will tell you that the O2 sensor is bad. Might not be so in early 80's. But that's where you can lose a lot of efficiency, the ECU uses the O2 sensor to trim the fuel mixture as lean as possible. Sleeper can help you with the fine details of getting it running best since he has one. I only know generalities.

-

He hasn't even established that his is set up right. Each of my questions is relevant to determining if it is. Doesn't matter if you or anyone else got 29 mpg. Could be that yours is actuality set up incorrectly, down on power, but up on gas mileage. Who knows. All that's here so far is one Z31 ECU with 19 mpg, one with 29 mpg on one trip, and one "same here" (converted to "regularly"). There's nothing here to work with. Let's get some facts.

-

He said he's trying to move the cam shaft. Should move pretty easily with a wrench or big pliers on one of the knobs (the rough part of the casting) on the shaft itself. Why he's looking at the dowel position with the crank at zero timing (#1 at TDC) is a question though. Should be looking at the notch and groove.

-

Sounded like you made an adjustment, things worked right, then they didn't work right. Not clear what's happening, or what the final state of the situation is. Anyway, the hydraulics should never hold pressure after you release the pedal, unless you have the rod to the MC extended to far. All pressure is released in to the reservoir when the pedal is up, on a properly adjusted setup. Someone just posted on this. If you can press the slave cylinder piston in by hand (that's what they did, it's a good test) and fluid gets pushed in to he reservoir, there's no way pressure can be maintained by the hydraulics. The problem is between the fork and the pressure plate. If you can't press the cylinder in because the slave cylinder rod is too long and piston is all the way back, that would be a problem, but with the adjustable rod, should be fixable.

-

I was asking the OP.

-

For every person who says they get 29 there's another guy who gets 20. 20 is the most common number I've seen. That's combined city/highway though. You're running an ECU designed for a different engine, one that should have EGR, and O2 sensor feedback. Do you have an O2 sensor connected to the ECU or are you just using one for AFR readings? Is EGR functional? Are you getting any codes from the Z31 ECU? Have you checked CHTS readings to be sure they're correct? Are you using a stock FPR or adjustable or an FMU? What is fuel pressure? Did you put the system together or buy it that way? There are lots of tuning tricks you can do to increase MPG. A simple one is to reduce fuel pressure. But that will have other effects also.

-

Could be that the TOB collar is too tall as you thought, and that expansion when everything heats up is causing the slipping. If you let it cool and it starts working right, then slips when it gets warm, that would be a clue. If so, that can only be fixed with a shorter TOB collar. You have an odd assortment of parts so nobody can really give you a combination of parts that might work. With the stock flywheel, the collar ears (where the fork rides) should be 92 mm +/- a few from the surface of the flywheel (bottom of the pressure plate cover). I'd guess that Fidanza dimensioned theirs for a straight swap, so 92 should work for you too, but who knows for sure.

-

Without knowing how many were sold these facts are meaningless.

-

cog·ni·tive dis·so·nance nounPSYCHOLOGY the state of having inconsistent thoughts, beliefs, or attitudes, especially as relating to behavioral decisions and attitude change.

-

Isn't the fuel added at the start of the runners? The pseudo-carb? Should be the same ratio for all, unless air is slipping by without picking up fuel then passing to individual runners unequally. With mulitport injection, you could see a runner air flow imbalance. but equal fuel injected for all, leading to varying AFR per cylinder.

-

Modern ECU's will hold the idle speed up to charge the battery, among other reasons. 2500 seems high but who knows what your algorithm is. And the idle speed was probably controlled by the Idle Air Control Valve. Lets air past the throttle blade, electrically controlled by the ECU.

-

At last you're not focused on AFR's. From too wet to too dry. Still no plug examination. The old counting horse teeth without looking inside challenge...

-

Then your plugs would be wet with fuel. Don't trust the gauge if you don't have to. You'd most likely smell gasoline also.

-

You've been lulled in to the false sense that the computer or phone screen will tell you all that you need to know about the outside (inside in this case) world. Happens to all of us. I've found myself checking weather pages to see what's happening outside instead of just opening the door. Remove a spark plug and look at it to see if you're flooded. Use a timing light to see when spark happens. Check fuel pressure with a gauge. Real touchy-feely stuff, right at the actual engine.

-

Rear stub axle bearing source?

NewZed replied to seattlejester's topic in Brakes, Wheels, Suspension and Chassis

I use this for the numbers - http://www.showmetheparts.com/timken/ Amazon has them. (2 x 32) + (2 x 17) + (2 x 6) = 110. Autozone too for a little more. Nissan probably has them also. -

Put it together, but only install two rocker arms. That way you'll only waste two valves, and dent one piston. Not positive but I think that valve guides can be damaged also. Clay is cheap. Worse comes to worst, it's hard to clean from the piston top. You know you should do this.

-

Since this is just an opinion poll, I'm going to say no you will not have any problems. Let us know who was right.

-

Better have that head from Datsun Parts/California Datsun/Al Allen checked out thoroughly. He's had some issues. At least two heads with the wrong lash pads, causing the cam lobes to ride off the ends of the rocker arm pads. Apparently Al is a likable guy but the people doing his work aren't experts.

-

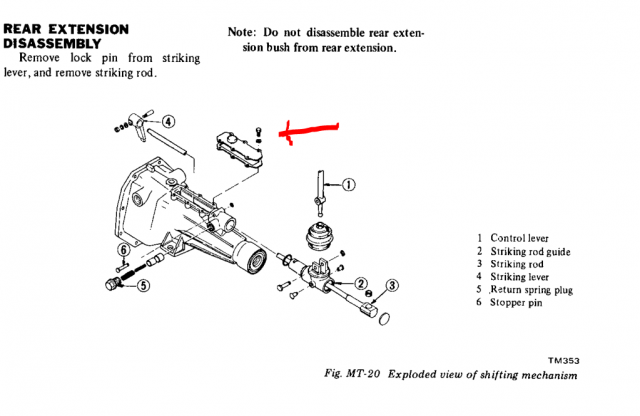

I don't know that it's a 100% guaranteed method, but those are real pictures of real transmissions. I've used both. Drawings of the plate are in the FSM MT chapters. Pretty obvious when you see it. Posted 76. Look in the 78 FSM for 78. It's smooth up there.

-

It's probably the float valve, either missing or stuck open, or the floats aren't floating, or they're bent. If you hold the throttle blades open you'd probably see the fuel flowing. Pretty basic fix and check. Idea - take the Holley apart and reset the critical settings. There are probably more books and instructions and videos out there about Holleys than any other carburetor. Might as well rebuild it while it's apart.

-

One other thing that gets left out on the binding issue is the bushings used for the differential. The stock rubber will allow a lot of side-to-side movement. The diff will get pushed to the side that has more room easily. They typical urethane locks the location down pretty well. Might be one explanation for the discrepancy in experiences.

-

Seems like a lot of rust, considering the number of times you rotated things to make sure they weren't bound. Maybe you got lucky. Or maybe your wrench was set to inch-pounds.