NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Did you try the other two orientations? They only fit one way although they look like they'll fit three ways. Spin it.

-

Bilstein no good or won't work?

-

Autocross and oil pressure... impending doom??

NewZed replied to shuttlefever's topic in S130 Series - 280ZX

I missed that piece. Seems more like the relief valve in the pump then, but if you've tried two pumps that would be unlikely. You said that you have a mechanical gauge but are you sure it's reliable? You might have replaced a very bad gauge, the stock one, with a still bad gauge. The liquid-filled gauges are known to be susceptible to heat effects. Details on the gauge might offer a clue. -

Need or needed? Is the rebuild done? How are the results?

-

Autocross and oil pressure... impending doom??

NewZed replied to shuttlefever's topic in S130 Series - 280ZX

How about an oil cooler? Pulled this link off of a Google search because it has a good illustration - http://www.elephantracing.com/techtopic/oiltemperature.htm -

Need help z31 ECU Swap + 280zx Turbo swap into '77 280z

NewZed replied to Milenko2121's topic in Ignition and Electrical

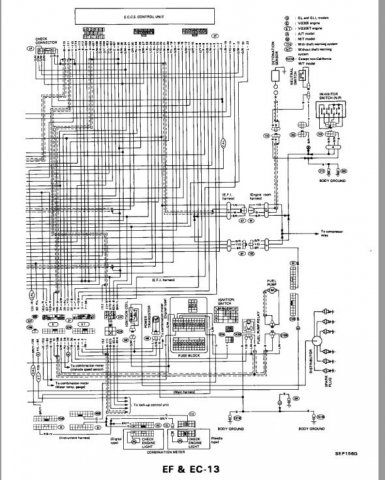

The power transistor (also called an "ignitor") controls current to the coil, and the transistor is controlled by the ECU. The 280ZXT transistor is out in the open on the coil bracket and looks like a quarter-sized metal object. The 300ZX transistor seems to be a little more hidden but still looks the same. There's a drawing of all of the parts on page EFEC-4. It's shown under the coil. The transistor does essentailly the same thing that the ignition module used to do on your 77's original system. Except that "dwell" control is handled by the ECU in the 300ZX ECCS, where it's handled by the module in the 77 system. If you don't have a transistor the ECU can't control the coil. The transistor is supposed to be at the end of one the wires in your wiring instructions. Page EFEC-13 shows the factory wiring to the coil, and how the L (blue) wire connects from the coil negative to the transistor (that's where it controls the coil ground). They do go bad sometimes, apparently, especially if not grounded correctly. -

Need help z31 ECU Swap + 280zx Turbo swap into '77 280z

NewZed replied to Milenko2121's topic in Ignition and Electrical

Page 93 says "CHECK GROUND CIRCUIT". If you're getting ignition pulse and the ECU isn't using it, maybe the ECU is bad. But you've tried three so that's unlikely. I'm guessing that your CAS isn't right. How did you measure "ignition pulse"? Did you use a "logic probe"? Or did you just measure voltage? You have to have the pulse. That's all I know. I would study the FSM. Inputs > ECU > outputs. Somebody will probably have some ideas if you show what and how you measured and the numbers you got. -

Need help z31 ECU Swap + 280zx Turbo swap into '77 280z

NewZed replied to Milenko2121's topic in Ignition and Electrical

Doesn't make a difference. Good luck. -

The FSM's don't even show an open option. http://www.nicoclub.com/FSM/Q45/ It will be expensive. You might consider the other LSD's, like the Subaru R180 option: http://forums.hybridz.org/topic/78123-subaru-wrx-sti-r180-side-axles/ http://forums.hybridz.org/topic/111779-betamotorsports-subaru-stis30-side-axles-wolf-creek-racing/

-

Need help z31 ECU Swap + 280zx Turbo swap into '77 280z

NewZed replied to Milenko2121's topic in Ignition and Electrical

Pretty sure both of those rely on the CAS signal. The ECU (ECM) gets the CAS "triggers" (more than one maybe) and causes the power transistor (ignitor) to cut current to the coil to cause spark, and grounds the injectors to cause squirt. Different times of course. Have you gone through the troubleshooting procedures in the FSM? Once you're wired in, you essentially have an 87 or 88 ZX, just 280 intead of 300. Code 21 is on page 93. Even tells how to check the power transistor. -

Need help z31 ECU Swap + 280zx Turbo swap into '77 280z

NewZed replied to Milenko2121's topic in Ignition and Electrical

Looks like you were almost where you needed to be to answer the last question. Or at least tell you which pins have power and which ground. Probably paged right over it. There are other pin-outs shown, like EFEC 84 for the CAS. That's where I'd be if was in your shoes. http://www.xenonz31.com/reference.html Attached a sample. -

Blocking the lines with bolts won't hurt anything. The hole in the back of the head is only used as a source of hot coolant for the heater core. If you block the lines the coolant will coolant wil just follow other paths through the head. 1977 uses an external voltage regulator. That might be the source of your voltage (charge light) problem, not the alternator.

-

The grease could have been there for heat transfer. The modules generate heat. You can buy a small tube of heat transfer goop at Radio Shack or an electronics store.

-

The "y" should be lower case.

-

water temp sensor to gauge wire

NewZed replied to AZGhost623's topic in Trouble Shooting / General Engine

You probably connected the BCDD wire instead. There's a three wire connector in the same area, if someone's had the wiring apart, the length of wire that goes from that connector, below the stock coil location, up and over to the sender might be missing. The wiring diagram will show youwhere the wire colors change also. Sometime colors change at connection points. -

Another AFM mystery...Can you help?

NewZed replied to atl_adam's topic in S30 Series - 240z, 260z, 280z

This option might be easier - http://forums.hybridz.org/topic/104419-s30-and-s130-wiring-harness-repair-kits-you-need-this-if-you-have-an-l28e-or-l28et/?hl=harness if you haven't torn things up yet. It gets good reviews. If I was in your boat and wanted to make the 78 harness work I would just open the Engine Fuel chapter of both FSMs and compare wires. There are small detailed wring diagrams in each, easy to understand and specific to the EFI harness only. Most wires will be the same, the ones that aren't might not matter. The fuel pump cutoff might be run entirely by external relays attached to the alternator and oil pump switch. www.xenons30.com/reference -

Ignition module. Fuel supply. Overheating relay. Overheating electrical connection. You need to narrow things down. Watch for symptoms like what the tach needle does when it dies, lights or other electrical affected, etc. Do other thngs still work but the engine won't start or is everything totally dead? Car goes, car dies doesn't offer much.

-

Search over at zcar.com for user "skittle". He has a writeup linked in his sig for using the GM HEI module in place of the ignitor. Seems to work.

-

Is the connector pinout at the ECU the same for a Maxima L24E compared to a ZX L28E? Curious if you can just swap the complete engine with AFM in the engine bay and the ECU in the cabin and be up and running with an L28, no funky tuning or tweaking.

-

New Cam and Rockers - odd looking at 500+ miles

NewZed replied to inline6's topic in Nissan L6 Forum

Maybe you just got a bad nitriding job. Too thin, uneven, too brittle... -

Did it backfire? Timing might be off. "I've got a 78 280z". What's the rest of the story? When's the last time it ran?

-

Squirt some starter fluid in the intake manifold (pull a hose) and see what happens. If it starts then dies, your injectors may not be opening. If it doesn't start then you may not really have spark to the plugs or you have fouled spark plugs, which also results in no spark. Edit - it may also be that your Honda avatar is bad karma.

-

Up to somewhere in 1980 the 5 speed has the same gear set in 1 - 4 as the 75 - 79 4 speed. 5th is an engineered add on. So it comes down to your desired freeway RPM or top speed, if you're considering the early 5 speed. If you want the more evenly spaced 1 - 4 ratios, they only come in the 5 speed anyway. That's the other reason people swap the later 5 speed in. First gear is different between the early and late 4 and 5 speeds also, so the rear ratio can be important. The very early 4 speeds, 72-74, have a much lower first gear to match the 3.36 rear ratio. All of the options have a 1:1 4th gear ratio. Talking about the transmissions available on the factory Z's and ZX's, not racing options. Ratios are listed around the internet and in the FSM's. Coincidentally, read Post #73 in this thread - http://www.classiczcars.com/forums/open-zcar-discussion/40249-hls30-01222-project-3.html

-

New Cam and Rockers - odd looking at 500+ miles

NewZed replied to inline6's topic in Nissan L6 Forum

There's a lot of good information in this thread. Were you just being extra cautious with the nitriding? Trying to avoid the new camashaft disaster? The comment above looks like Kinetic doesn't recommend it, but doesn't recommend against it either. But does say that the standard finish works best which implies that they've seen both in action. Googling "estas camshafts" brings up some interesting web sites also. -

Fuel Pressure Regulator (FPR) Need help!

NewZed replied to Jason280zx's topic in S130 Series - 280ZX

You might have the hoses at the rail switched, in the engine bay by the filter. That would pump directly to the return of the FPR. Note - I've only verified that an Aeromotive FPR won't flow backward, not a stock one. But I think that the general concept of regulation is the same. The fuel pushes on a much smaller area in reverse.