NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Fuel Pressure Regulator (FPR) Need help!

NewZed replied to Jason280zx's topic in S130 Series - 280ZX

Maybe you connected hoses backwards at the tank. Pumping in to the return line instead of the supply line. The FPR won't flow backward, so you'll end up with the 90 psi or more that most aftermarket pumps will produce. Ot it could just be a loose hose clamp. Doesn't sound like you've looked to see where the leak is. "a hose beneath the car"? -

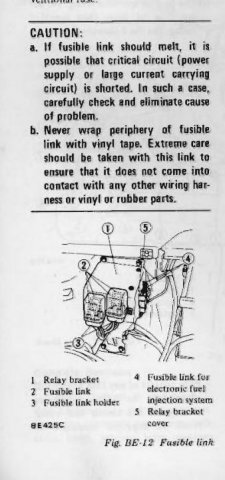

The links are sized to the amount of current that they're designed to pass. They come in different sizes. This site seems about right for you, although the information about the red links is incorrect and/or incorrectly applied - http://atlanticz.ca/zclub/techtips/fusiblelinks/index.html

-

Here's a good start. You're right, there used to be something next to that link holder. Probably worth your while to figure out what the PO did to those wires.

-

Driveshaft removal, NOT the bolts

NewZed replied to noelawinslow's topic in S30 Series - 240z, 260z, 280z

The center of the yoke has a raised, machined portion that fits in to the machined center of the diff's pinion flange. It's a tight fit. Beat on it from two sides with a piece of wood or plastic/dead blow hammer to wiggle it out. If you use a chisel in the gap make sure to file or grind down the divot you create so that the you have a flat surface when you put it back together. -

Super-duper slick-as-snot trans fluid??

NewZed replied to shuttlefever's topic in S130 Series - 280ZX

Does yours need a change just because it's time or because it has shifting problems? Some of the newer "syncromesh" fluids are lower viscosity (~5W-30) than the older fluids. They're designed for today's transmissions. -

Curious - did you check wipe patterns while you were working on it? I get the impression that the guy buys used parts, shines them up, assembles them in to packages (custom?), then resells. You might have a grab bag of parts assembled to make one engine, with little atention paid to the important details.

-

Measure fuel pressure and check your cooant temperature circuit resistance at the ECU connector - sqwawk, cracker...

-

Sounds like you have a NAPS-Z engine. The two plugs are for emissions purposes. This is probably the wrong forum for your problem, have you tried any of the Nissan truck or Pahfinder forums? These guys seem to cover a wide variety of Nissan engines - http://community.ratsun.net/ You could probably convert to carbs with some work, but would you be able to pass CA emissions? http://en.wikipedia.org/wiki/Nissan_Z_engine

-

Were they sparks flying at any time while you were working on it? Maybe you blew a fuse or burned a fusible link. You said the EFI relay works, how do you know? Have you checked for power to the ECU at the connector? Get a multimeter and check the basics. Power to the ECU, power to the injectors, power to the fuel pump while Starting (on the 280Z's you can disconnect the starter solenoid wire to test the fuel pump, I don't know how the ZXT system works). Make a list of stuff that's right and stuff that's not.

-

Compare your first post comments, above, to your last post. You seem to be losing track of what works and what doesn't. You have to be methodical and careful to diagnose engine problems. You're all over the place and not making sense, in just one day.

-

New Cam and Rockers - odd looking at 500+ miles

NewZed replied to inline6's topic in Nissan L6 Forum

It would be good to see all of the details on both setups. Cam grinder, shaft material, nitriding on just one or both, break-in lube, oil used for the first 500 miles, ZDDP, etc. From what I see about nitriding, it's supposed to reduce galling. Metal to metal contact is always bad so maybe it's just oil quantity. I didn't see anything about oil type in the previous posts. Maybe the nitrided surface needs polishing before use to be effective, since it's too hard to wear in. I seem to recall that the process leaves a rough surface behind. Interesting problem. Edit - the nitriding process would good to know also, since there are several. -

Can you up the idle speed enough to keep it running and get a timing number? Or get one while cranking? That's what I'd do.

-

New Cam and Rockers - odd looking at 500+ miles

NewZed replied to inline6's topic in Nissan L6 Forum

I haven't built any engines in real life, only in my head. I just threw that out as something that might match the evidence, a brainstorming thing. I could be way off. Since everything is installed, it would be easy to measure how much room is left in the springs at maximum lift. Valve lash generally gets looser when hot, but it's hard to imagine what the springs and valves might do. You might find you have tons of room and can think about some other potential cause. It might be something as simple as poor heat treating on the rocker arm pads. -

Maybe Gollum wrote too many words. The engine doesn't matter. Injector impedance must match the electronics of the EMS. Specify the EFI system - ECU, harness, car it came from, details like that - and someone might have an answer.

-

New Cam and Rockers - odd looking at 500+ miles

NewZed replied to inline6's topic in Nissan L6 Forum

WAG on inline's problem - coil bind on the springs? Maybe after everything gets hot. Can't really tell from the straight-on picture angle but it looks like the wear is happening evenly before and after maximum lift, when you'd think that it would happen where the ramp starts and on the way up. -

280z Intake EGR Plug size?

NewZed replied to Milenko2121's topic in Trouble Shooting / General Engine

You might take another look at the EGR device. On a 1978 N47 manfiold once you block the top with a plate, the bottom ports don't matter anymore, unless the passages are rusted through. You only have to worry about the exhaust manifold supply line from the exhaust manifold, which you don't have. The turbo system could be different, I've not seen one up close. -

280z Intake EGR Plug size?

NewZed replied to Milenko2121's topic in Trouble Shooting / General Engine

Pretty sure that an M16 bolt with a notch ground in to the side will self-cut its own threads in to the inside of the pipe on the exhaust manifold. If you can't get the threaded portion out (I couldn't) and ended up breaking the pipe off. Might help if that's what you're talking about... -

The J30's are VLSD. They're shown in the pd chapter of the FSM if you want to take a look. Many of them have a sticker on them that says "viscous" or similar, I believe. http://www.nicoclub.com/FSM/J30/ There's another thread on Hybridz from a guy who used one open R200 axle/companion flange, and cut and welded the u-joint half-shaft flange on to the VLSD axle for the other side. Same as before, says it works but not recommended. The only easy, plug-n-play way to get limited slip seems to be the 87-89 Z31 CLSD's. All of the other options require welding, and/or machining (adapters with mix and match CV shafts), or buying a kit from someone who's done the welding and machining. It's a bummer.

-

You can do all of that but your open stub axle won't engage the two side of the VLSD viscous clutch. You'll still have an open differental. One of the VLSD axles is much longer than the similar axle in the open diff. There's a thread on Hybridz somewhere from someone who cut the two axles and welded them together to make a hybrid axle. It seems difficult and most pros don't recommend welding axles but he did it and says it works. No idea how it's holding up.

-

I screwed up (or got screwed up by the post). I saw 3.9 and thought you were talking about the differential. Not sure why you used 3.9 to describe a transmission. Although you should consider that point (3.9 vs 3.36), since the ZX 5 speed will be boggy in 1st with a 3.36 diff. But that wasn't your question. The 1971 240Z used the 71B type transmission. It should be a straight swap. The transmissions are essentially the same, except for the gears. I'm not sure what 74_5 is referring to. You might have to carve some space out of the shifter opening for the shift lever in 5th gear or bend the lever. I have an early 71 driveshaft in my garage and it is the same on the ends as my 280Z driveshaft. Omly the length is different, because the early z"s had the diff set forward. There's a ton out there on the internet about the swap you're planning.

-

Isn't member Burleigh making a brace for this - http://forums.hybridz.org/topic/98295-steel-brace-for-r200-clsd-finned-cover-in-s30-new-list-and-design/ ?

-

L28 Rough idle after head gasket. Need help.

NewZed replied to Jspec603's topic in S30 Series - 240z, 260z, 280z

The thermotime switch only runs the cold start valve. Once the engine starts, it's useless. Often people look at the CSV as a potential leak source for excess fuel but it's uncommon. Worth a check though. You're deep enough in to it that sitting down and reading the Engine Fuel chapter from page 1 would really help you out. It will help focus your feelings. Good luck. -

L28 Rough idle after head gasket. Need help.

NewZed replied to Jspec603's topic in S30 Series - 240z, 260z, 280z

Dan might be on to something. ~36 psi is the right number without the vacuum hose, ~26-28 with (in my experience) with the hose connected and engine idling. If the vacuum hose is connected, check it for gasoline. It should be dry. Your FPR might be damaged. By the way, your first post "videos" are just pictures. On my computer.