NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

You can also pop the circuit board out of that switch by bending the four metal tabs back and clean up the contacts, without removing the switch from the steering column. Worth a shot before replacing. I took the halfway approach on the relays, and spliced one in to the red wire that feeds the fuse box. This takes the load off the headlight power contacts, which is where I found the pinhead size pit and corresponding metal deposit from years of sparking, but leaves full power through the fuse box and dimmer switch. Not as satisfying as protecting all of the old hardware but it takes one weak link out of the system. The power switch was where I was losing voltage anyway and is the part that was getting warm. Plus the wire is easy to get to and close to the battery positive terminal.

-

What did the temperature gauge show while running, after you got all the new parts installed and the radiator refilled?

-

Turbo Swap, No Spark..What's Not Hooked Up Right??

NewZed replied to billseph's topic in Ignition and Electrical

Well then, the OReilly Auto web site will show you a list of wrecking yard cars to check - http://www.oreillyauto.com/site/c/detail/IDI0/140148.oap?year=1982&make=Nissan&model=280ZX&vi=1209361&ck=Search_ignition+module!s!control+unit!s!ignitor_1209361_-1&keyword=ignition+module!s!control+unit!s!ignitor Click the Compatibility tab. If the link doesn't work, search "ignition module, that's what the ignitor is listed under. -

Turbo Swap, No Spark..What's Not Hooked Up Right??

NewZed replied to billseph's topic in Ignition and Electrical

Seems like one of the Megasquirt coil drivers should work. It would need protection from the elements, proper installation and a decent heat sink, but functionally it's designed for the job. Cheap enough to experiment with also. http://www.diyautotune.com/catalog/bosch-bip373-coil-driver-mod-kit-p-230.html -

Alternative AFM boot replacement

NewZed replied to ttodhunter's topic in S30 Series - 240z, 260z, 280z

Groovy, even better. You do know that you'll have unmetered air (bypassing the AFM) in the intake manifold now, through the PCV valve and hose, with that breather on the rocker cover? Through the breather, down through the oil drain holes and through the PCV port in to the manifold. Should create a leaner mixture, idle quality would be the first thing noticed. Maybe you've blocked the PCV port, or it was already blocked, or "tuned" your AFM to offset it? Nothing wrong with modifying, but the EFI system and PCV system were designed for a sealed crankcase. -

Alternative AFM boot replacement

NewZed replied to ttodhunter's topic in S30 Series - 240z, 260z, 280z

You didn't put a winky face after this statement to show you were joking. That's hilarious. Have you started the engine since you modified it? -

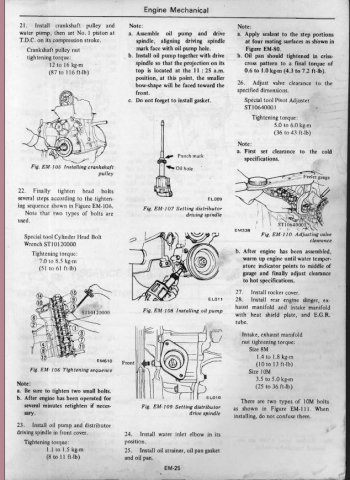

The instructions in the FSM are not good enough? I don't see the problem, maybe I'm missing something. Page from 1978 FSM attached.

-

Don't you want to "give back" and tell people what the problem with the other pump is? Simple courtesy.

-

It's described with pictures in the Engine Mechanical section of the FSM, page EM-25 if you use the 1978 FSM (a good clear copy with sections separated, from the http://www.xenons30.com/reference.html site). In the Engine Lubrication section there are descriptions of taking apart and assembling the pump, checking the regulator valve, and measuring clearances. Could you remove the bolt and pop the oil regulator valve on your old pump, while you have it out? See if it's stuck or clogged? It would be nice to know if that was the cause for your problem since the pump was apparently pumping plenty of oil. Honestly curious, not taking any pokes at your method.

-

If your battery has over 12 volts, and you're seeing those low voltage numbers, you might have your coil (-) grounded. Current is flowing, causing a voltage drop. To be clear, by B, I meant the wire that connects to the B terminal on the HEI module, measured with it disconnected. ZX FSMs is short for Factory Service Manuals (FSM) for the 280ZX (ZX) cars,which have the type of distributor that you're using. I got curious and went out and tested an old ZX distributor I have and with a digital multimeter you can see a voltage change across the red and green wires when spinning the shaft. An analog meter might not catch it. The pickup coil is underneath the circular metal ring with the 6 inward points, along with a circular magnet. Did you test resistance on it? Looks like this - http://www.oreillyauto.com/site/c/search/Ignition+Pickup!s!Stator/C0417/C0334.oap?year=1982&make=Nissan&model=280ZX&vi=1209350&keyword=stator

-

The shift pattern is the typical 5 speed pattern, 5th is up and to the right, reverse is right below it. 5 speeds were standard equipment in 1978 if you got a manual transmission, although a 4 speed might have been a factory option. Keep them dry so they don't rust up and someone will find a use for them.

-

It sounds like you had the right wires on the right sensors in the beginning,if you did all that driving around. Your other symptoms sound more like fuel supply problems. Maybe you got your connectors wrong at the thermostat housing. The extra sensor you're seeing in the thermostat housing is probably the thermotime switch. It controls power to the cold start valve so the engine doesn't flood when starting. It has the same connection type as the temp sensor and it's common to get the two switched since they're right next to each other. You can be sure which is which by testing resistance against the table in the FSM, then test at the pins at the ECU connector if you really want to be sure the ECU sees what it needs to see (corroded connections, shorted wires, etc., on the way to the ECU). The pin numbers are in the FSM Engine Fuel section, along with the resistance table. One turbo per cylinder will be new, looking forward to seeing that...

-

BluDestiny, the first post,last sentence, says they're using the P90 head. The resistance v. temperature curves are the same (they're both shown in the FSMs), they just moved the location of the sensor from the thermostat housing to the cylinder head (apparently after 1979). Your 79 wiring has the sensor plug up by the thermostat housing, the 82 wiring has the sensor plug between cylinders 5 and 6 above the starter. You can either extend the wiring or install a coolant temperature sensor in the thermostat housing. Tweaking the AFM is possible, I'm sure. I was just pointing out that your engine doesn't match what the ECU and control components are designed for. Why did you replace the N47 head with the P90? Just curious, nothing wrong with a Frankenmotor if that's all you have available.

-

I assume it's the original 1978 N47 head / N42 block engine and the original early-style 5 speed? If it has a later ZX 5 speed, I would be interested. I'm looking for a spare. That setup, even original, is still a nice swap for somebody, if the engine is in decent shape. It's a few more horses in a 240Z. Take car with the wiring harness and EFI parts and someone will take it. p.s. If you're giving them away I would take them just to add to my spare parts collection.

-

You need the "head sensor", AKA CHTS. Without it, it will run rich all the time. Good when cold, bad when warm. Flooded probably when it dies. I forgot to connect a water temperature sensor recently and that's exactly what the engine did. Ran good, ran bad, died, fouled plugs. Does it smell gassy? I would pull the plugs, see how fouled they are, clean them up, get the CHTS connected and try again. One problem you might have even after you get it running is poor running and low power due to low compression ratio. The P90 head with the typical dished pistons will give ~7.4 CR. Good for turbos, but your ECU is probably tuned for CR in the mid to high 8s.

-

Here's a place with most of the parts - http://www.datsunstore.com/index.php/cPath/203_206_357_430 I think that the owner's name is Oliver, and he's been around for quite a while. He could probably get the other pieces you'll need. Here's another possibility - http://www.modern-motorsports.com/catalog/product_info.php?products_id=74 There's a guy near my location with the back half of a 75 280Z being parted out. 3.54 R200. I don't think he'll ship though.

-

With a typical worn L6 pump you should have been able to drive around all day at under ~3,000 RPM, since they seem to start at ~15 psi and don't hit high pressure until you get the RPM up quite a bit. Was a new pump was part of the rebuild? You can take the regulator valve apart from the bottom of the pump, without removing it, if I read the picture in the FSM right. Big bolt, washer, spring, valve. Might be worth a look before you install the new pump. Edit - there might be a few more parts in there - http://www.carpartsmanual.com/datsuns30/DatsunZIndex/Engine280Z/OilPump/tabid/1610/Default.aspx

-

Edit - a blocked main gallery, after the oil pump, could also lead to high pressure, and take the oil filter relief valve out of the picture. Might also explain the groaning bearings.. The oil pump regulator valve should still hold pressure to ~80 psi though. Good luck.

-

So that's two for the oil pump check valve. So you two are saying that a good L6 oil pump will generate enough flow to overrun the oil filter relief valve with enough pressure to lift the oil filter off its base, blowing oil out, if the oil pump regulator valve is stuck or blocked? Or maybe so much flow is generated that the main gallery after the filter is a restriction, so the filter relief valve doesn't matter? Just trying to learn something. That seems like a lot of oil and a lot of pressure. Sounds interesting.

-

But what does this mean? At. At where? I would focus on figuring out where "at" is (why am I thinking of Bill Clinton?).

-

You can poke the check ball in with your finger or a soft tool with the oil filter off, I believe. EL-4 in the FSM describes service and replacement. A comment from the logical thinking perspective - if the oil is not coming through the sealing surface, where is it coming from? Blowing out through a seam in the filter? Is the filter damaged? Why are you focusing on the filter if you don't think it's leaking at the filter seal? Check the oil pressure gauge. Maybe you knocked it when you were changing the filter and it's cracked or broken at the base. A small hole at high pressure would spew.

-

There's not a whole lot to the oil filter and it's sealing surface. You just need to stick your head down in there with a bright light and see what's going on. The L6 has the most accessible oil filter mount and sealing surface that I've ever seen.

-

Yes. It screws on easy by hand, with no leaks. Take the filter off and take a good look at the sealing surface and the threads on the filter mount. Remove the rubber gasket from one of your old filters and stick it on there to see where it sits. Someone in the past might have scratched the sealing surface, or buggered up the threads.

-

PH8A is one of the correct FRAM numbers. TG8A doesn't sound familiar. Edit - p.s. - The Autozone guys can tell you the correct part number...

-

Wiring harness repair kit - eliminate your electrical gremlins!

NewZed replied to FricFrac's topic in Ignition and Electrical

Are they the springy clip Volvo/BMW type connectors or the Nissan type with the removable wire? Pictures would be good. Are you selling at cost?