Search the Community

Showing results for tags 'manifold'.

-

I have a L28ET exhaust manifold from a 83 280ZX Turbo, unit was made of three pieces, and put together with two bellows couplers. Here is a picture of the manifold in question, found on mrjeffzx xtreme Nissan 280zx Turbo page: https://www.angelfire.com/extreme/280zxt/images1/Euromanifold.jpg One of the bellows has a crack in it and needs to be replaced or if possible repaired. I don’t think it would be possible to weld it, at least not with my welding skills. I tried finding this part on RockAuto, eBay, FAST, Nissan4u and a couple if other sites without any luck. Not even a part number Therefor I thought I should try asking here for help. Maybe there are alternative ways of fixing this. Any suggestions are welcome. I have attached a picture of the damage (The white stuff is exhaust paste since I first thought it leaked around the clamps) Thanks...

-

I have several things for sale I have removed from my Z over the years. Everything is located in New Jersey and mostly negotiable (I'm not up to date on most of these prices so here's what would make me happy). Weber 32/36 DGV carburetors with E88 manifolds, balance tube and linkage that should be complete. These could probably stand to be rebuilt but did run when I took them off ~2 months ago to install triples. $250 Unused Cannon triple Weber DCOE manifold with linkage and carburetor mounting/insulation kits: $250 sale pending Old Canon exhaust manifold. My research tells me it is a Canon manifold which haven't been produced in some time. Comes with a collector to a 2.5" exhaust: $150 Four Eagle Alloy wheels. My last measurement put them at 7.5" wide with 4x114.3 and 4x100 patterns. All of the tires pictured with these are 225/50R15. Two of the tires are badly scalloped although the other two are Toyo Proxes4 and in decent shape. The tires can be dismounted and discarded if desired, I don't expect anything for them. $200 240Z master brake cylinder. Came off my '72. No leaks or bleeding between seals when it was removed around May. I went with a 15/16th's cylinder for bigger brakes: $50 240Z distributor with a Pertronix electric ignition conversion box and 3 year old NGK plug wires. Upgraded to a 123 Ignition unit: $75 Finally, the pièce de résistance, one fabulous aftermarket 'Z' steering wheel. I don't know a thing about this other than it will bolt right in place of a factory steering wheel and use the original horn contacts. It was the first thing I took off my car so a $20 bill would thrill me: $20 SOLD

- 4 replies

-

- carburetor

- manifold

-

(and 1 more)

Tagged with:

-

From the album: ITB's

-

From the album: ITB's

-

Hey everyone, This is my first post to the forum, and I have a project and a few questions to share. I'm currently working on building a 6 carburetor setup for my l28 and have decided to use 6 30mm Mikuni motorcycle carburetors. I've selected these based on the airflow requirements of the engine while accounting for volumetric efficiency, engine speed, and of course engine size, and by comparison to some other carburetor setups (triple webers, various SU setups, etc). Needless to say, the Mikunis won't be compatible with the existing N33 intake manifold I'm currently running, so I plan to fabricate one from steel sheet and tube. My question relates to the ID sizing of the new intake manifold. I've read a rule of thumb that says the throttle body at the base of the carburetor should have an area that makes up 80% of the intake manifold cross sectional area. Based on this, I'm approximating an intake manifold ID of 33.54mm (see calculations below) Area of throttle body at carburetor base= (15mm)^2*3.14=706.5sqmm Area of intake manifold =.706.5/.8=883.125sqmm Radius of Intake manifold=(883.125sqmm/3.14)^(.5)=16.77mm Diameter of intake manifold=33.54mm Can anyone confirm whether this 80% rule of thumb is safe to go by? I know there are other considerations to make when it comes to resonance tuning and airflow, but I've had little luck finding anything conclusive. I'm also considering sizing the new intake manifold to match the ID of my existing N33 manifold and N42 head. Given the simple construction of the new manifold (going with steel tube and steel sheet), fewer changes in diameter might be better. Abrupt changes in diameter of the tube will cause turbulent airflow, which, while potentially useful for achieving an even fuel mixture, could also reduce throttle response (thus my reasoning for matching the new manifold to the head). Does anyone know the size of the holes where the head meets the intake manifold? I've done some searching around the forums but am unable to find this bit of information. Thanks for your help! Any and all advice is welcome. pkz

- 48 replies

-

Blew my turbo on the way back from SoCal. Rather than buy a replacement turbo, I figured it's time for an upgrade. So I did some research and bought the ISR(formerly know as ISIS) Performance RS3871. I'm planning on doing a top mount set up and haven't seen any info on what will and what won't work fitment wise. Is it their any issues that I need to worry about? I've seen photos of top mount set ups on the interwebs so I am just hoping is super easy and all I have to do is buy the top mount manifold and the supporting mods. BTW: these are the turbo specs Compressor side 3" inlet Exhaust side 0.64 A/R turbine housing, Results: This turbo is rated up to ~380hp.

-

I am beginning to source parts for my S30 - L28et swap and already have the long block (P90a - F54), but need everything else. My car is a late year-260z (December 1974). I am also looking for advice on transmission options as I have found endless information (somewhat difficult to sort through) on options. My car is an automatic if that makes a difference. I am looking to buy: Transmission (T5- or other??) Manifolds (Intake and Exhaust) Turbo ECU Wiring Harness Dizzy Fuel Rail everything else I appreciate any help or advice! Thanks! -Josh

-

Hey guys and gals, wanted to update you on some new Raw Brokerage goodies: Our new billet merge collector manifolds are everything our traditional manifolds are plus more. Made out of one piece 304 stainless steel billet leaves no room for error with runner transition into the turbo. These manifolds allow you to continue to retain both power steering and A/C and clear up to 4" downpipes on both LHD and RHD chassis. Good for those with 240sx RB swaps and upgraded Skyline chassis'. For more details: http://www.rawbrokerage.com/raw-brokerage-billet-twin-scroll-top-mount-turbo-manifold-rb20-rb25-rb26/ We'll have a S30Z specific model made if there is enough interest. Let me know. Thanks for your continued Raw Brokerage support. Together we can continue to create and provide bigger and badder RB20 RB25 RB26 and RB30 parts for the community of enthusiasts!

-

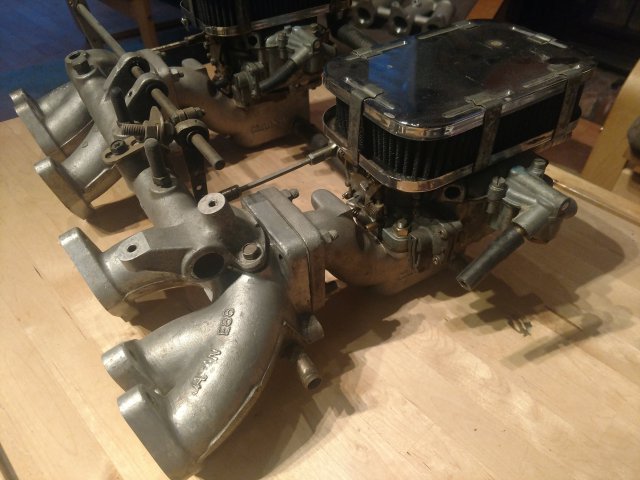

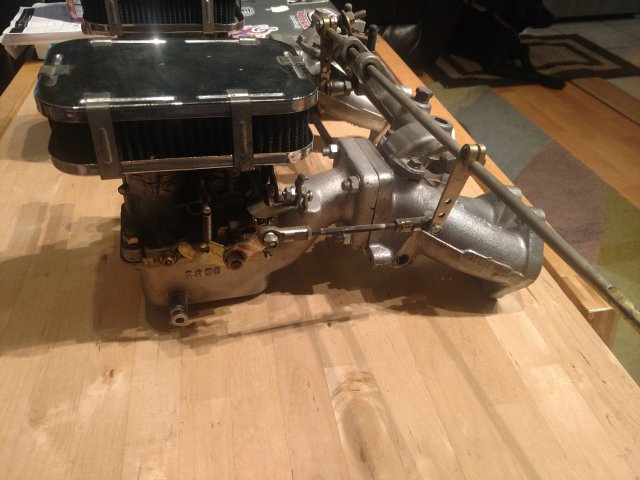

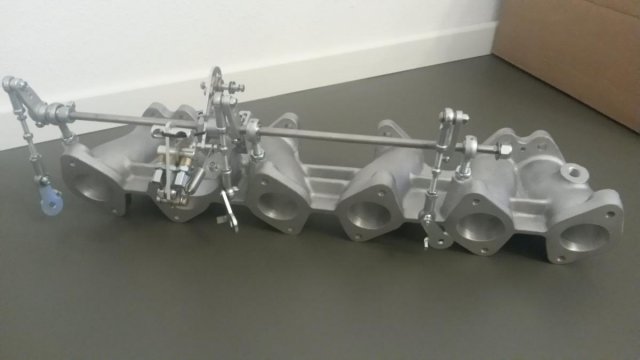

I have searched the internet far & wide to no avail trying to find photos/reviews of the Mangoletsi manifold before buying. Therefore, I hope this post will give the next person looking to switch to triple webers more complete information. The manifold is made by Mangoletsi in the UK. It is built to fit DCOE 40 but they also produce an option for DCOE 45. It is extremely well built, every part looks and feels to be high quality. It comes with both the standard rod linkage as well as a cable linkage (can be seen in one of the photos). Included in the kit is a port matching template to make the block openings fit the manifold perfectly. I have not had the chance to install the manifold as the car is undergoing a complete restoration, but so far completely recommend it. Enough talking, time for some photos! Although it did take a while to have the manifold built, it was worth it.

- 10 replies

-

- Mangoletsi

- Manifold

-

(and 1 more)

Tagged with:

-

I am in need of a clean 280zx exhaust manifold for the P79 head. A stud broke and I have clamped down that side just to be able to drive it short distances but it may have a small leak causing excessive noise that makes it hard to listen for any unwanted sounds during my engine break-in period. Needs to be leak free and broken stud free. I am open to headers if you can cut a good deal on them as long as they relatively new, come with adapter, and are from MSA's newer batches of headers, since I know a few Z guys in my area who bought them when they first came out and found them to be less than satisfactory (apparently MSA did some work and updated their product). I will pay shipping as well on any purchases.

-

It's for a Turbo conversion

-

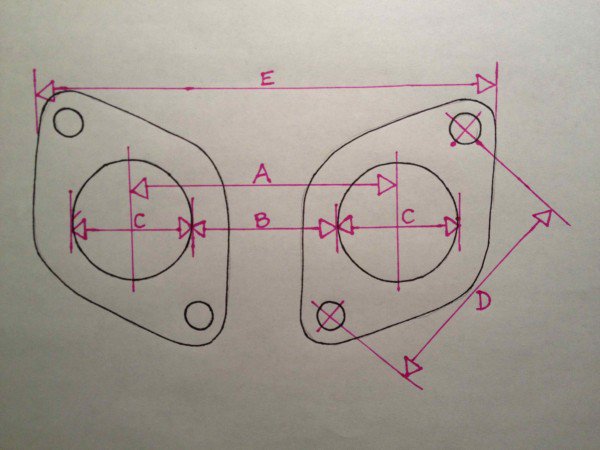

I recently bought a weber manifold for a 240z L24 but I'm not sure whether it was made for 40 or 45 dcoe. I measured the "C" value (in the attached photo) at 4.6 cm. Does that indicate it was made for a 45 dcoe? I dont have any carburetors to compare the diameters for the two and couldnt find anything online. On the producers website they have a kit listed for 40 and separately one for 45 so I am guessing they are somehow different Any help in finding out which carb fits the manifold is greatly appreciated!

-

Hello Hybridz, First, a little about myself and our little startup company. I’m a mechanical engineer with a heavy background in manufacturing and technology. My first car was a ’77 280z. It was a great little project car and a lot of fun to tinker with. I ended up doing a turbo/holset/megasquirt/edis conversion and driving the rings off of it—what a blast. I ended up selling that car and buying a ’74 260z SCCA race: Holley 4 barrel, big cam, headers, light flywheel, straight pipes. It generally terrified passengers and sounded like Barry White gargling wasps. Those two cars gave me a love for Z and an appreciation for the fantastic and knowledgeable community of HybridZ. Our company is a little one at the moment, with three engineers and assorted consultants. We started just last year and have been slowly piecing together the machinery to offer a wide range of rapid prototype services. Our primary objective is to help migrate high technology from the aerospace/medical industries to oil/gas and automotive. Our core technology is Electron Beam 3D melting of exotic materials. We are the only small private company in the world to own an Arcam EBM printer. With over $2mil invested in the machine, training, and R&D, this represents our commitment to staying on the bleeding edge of additive manufacturing. This machine uses a 60,000v electron beam to fuse powder, slice by slice, inside a vacuum chamber. The result is a 99.9% dense, tempered, high tolerance, ASTM-rated material straight out of the machine. The unique geometries that can be produced with this process allow incredible design freedom. The primary material we use is Titanium Ti6Al4v, with Inconel 718 also being possible. Other services include high temperature Ultem 3D plastic printing, precision miniature Stainless/Inconel investment casting, tensile testing, coating, finishing, CNC, and more. Thus far we've worked in conjunction with academia and various O&G/Aero companies to development solutions for their unique needs. Since we’re small and will have to work hard to achieve name recognition for the processes and our company in particular, we’ve agreed to hold various promotions through the different hobbies that our engineers have had. Cars, guns, rocketry, sports, and more. We are really trying to reach out to all those engineers out there that wrench at night and drive a desk designing for industry by day. My car buddies have been tossing around the idea of custom Inconel turbo manifolds. We’re up for trying anything that is a good demonstration of the technology. CAD-to-Metal Contest details: · The most innovative and well-engineered design will be awarded with our rapid prototype services 100% free. Services include Ti6Al4v 3D fusing or Rapid-vest Stainless/Inconel Casting. · Members have until July 1, 2014, to submit designs. Only 3D CAD formats are accepted but a short PowerPoint design presentation is suggested. · Winner will be announced July 4, 2014. · Submissions may be posted here or emailed directly for privacy. · Design components must be sub-system such as intake, exhaust, induction, fuel delivery, power transmission, etc. No complete 7-liter titanium engine blocks, guys! · Geometrical and tolerance limitations do apply. 210mm/210mm/170mm for Ti6Al4v and 1000mm/1000mm/500mm for Stainless/Inconel. Typical tolerances plus minus .007” prior to finish machining. We’ll be running a much larger and more public promotion through GrabCad next month, but this project is just for HybridZ. I’ve seen really fantastic work in the areas of custom intake and exhaust manifolds made on this forum. I encourage all those individuals to participate in the contest, and let us help you realize those ideas. This is truly a no-strings-attached contest. I simply thought it was important to give back to the community with our capabilities. I look forward to seeing your ideas and giving feedback during the design process. Good luck! Sincerely, Andrew McCalip Masson Development amccalip@massondev.com @Massondev

-

I'm looking for an apater to bolt a t3/t4 up to the stock zx manifold. I've looked on ebay and found several but it looks like there are a couple different flanges that coupled the t3 to different makes, so I was wanting one that fit our cars, obviously. lol The flange on my compressor housing is bolt hole, center to center 3" x 1 1/8". Thanks fellas

- 3 replies

-

- turbo

- compressor

-

(and 3 more)

Tagged with: