All Activity

- Today

-

280z 1jz track build from a pile of parts

flatout replied to flatout's topic in S30 Series - 240z, 260z, 280z

I have been way to damn busy last two weeks so haven't gotten much done. I did get to borrow a set of seats I thought I wanted, but they just really don't fit. being a full containment seat they basically stick out the window. I was also pretty disappointed with the quality. My buddy had these for one season in a drift car that lives mostly in a trailer or garage and they were already real faded from the sun and had plenty of little rips and tears after just one season. I ended up buying a set of kirkey intermediate road race seats. I have one of these in my other car and have put 100k street miles on it so figured id be happy with another set. I may add some head support pieces but for now I'm happy with them. Also think I got my wheel picked out. little teaser for now until I can get some tires and sit this thing on the ground - Yesterday

-

I just posted this to ZCAR: “Receiving periodic/automatic emails that say: ‘Come back, we’ve missed you!’ Sometimes life gets busy enough that I forget to login. I appreciate getting occasional emails reminding me of this great resource. I also think it helps keep the involvement up in the forum. Excellent idea. Thank you.”

- Last week

-

The wheels I want for my 260Z happen to be 16" x 8" with 225/50-16 tires. I'm told they would fit with the CORRECT offset. Anyone know what that might be? Nick

-

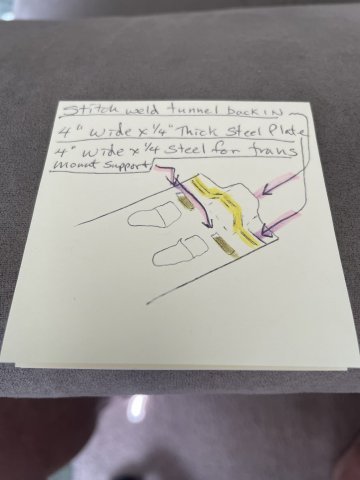

02-26-2026 ATLAS Z UPDATE: Today I got my rollbar and rear strut brace back from the powdercoater as well as the tunnel I dropped off to sandblast. The rubber is still on there, but this yucky sticky layer of honey look goos (glue) is gone. I also picked up my trans mount, he welded it up and added gussets on both sides out of 1/4" plate. I painted the back side quickly before I ran out of paint. Ready for the next day in the garage! P.S. self tapping screws and sheet metal (18 ga) here and ready to built it back, then the welder will stitch weld it and weld the plates over the top and over on both sides to the door jambs. 1/4" thick, 4 inch wide plate. Car will be overbuilt int his area like I did with the radiator support. 350-400 horsepower you really have to, even with the reinforced floor I have.

-

Mitchel0407 started following Exposed's 1jz Build

-

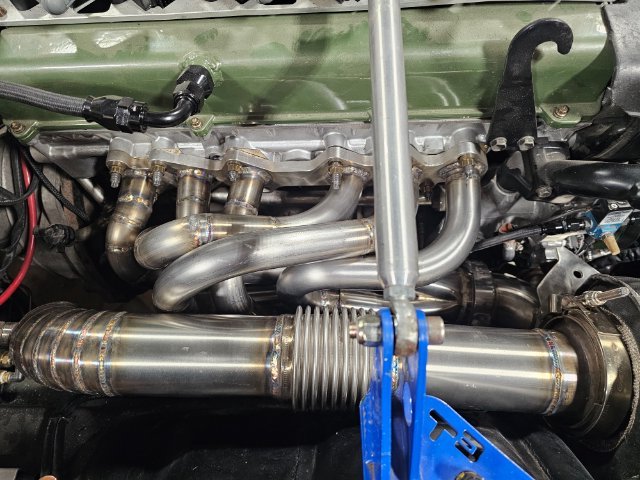

incrdibly nice work. Keep it up! can't see the flange on the turbo header....you hid it!

-

this is very cool, I will be following along. Love the custom work. I am doing a 1jz swap myself at the moment so nice to see another with another person fab ideas

-

- Earlier

-

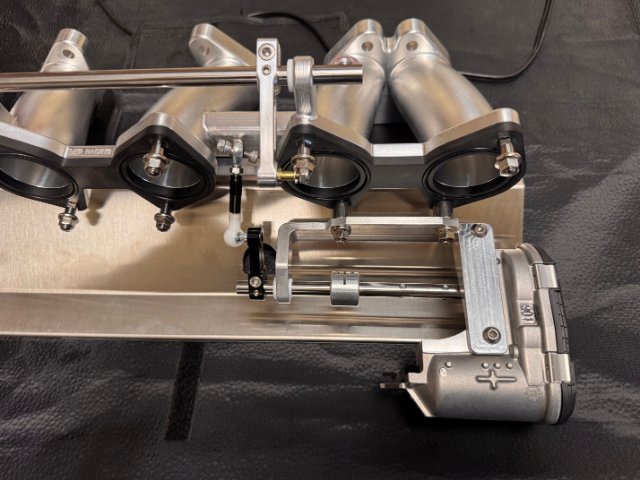

was able to make the template for the back of the throttle.....will bolt right to a raised area right there with 3 threaded holes. good luck!

-

02-21-2026 ATLAS Z UPDATE: I made the template for the electronic, "drive by wire" throttle, and then started bolting together the parts of my Skillard rear deck flooring. I sits about 2 inches up from the hatch floor. There are some pieces that are missing, so I went as far as I could with that this time, and then I jumped on getting a transmission mount built. I used a 6" steel square piece as a spacer, since I have such a large space to fill up. I have it 90% done, I will have it welded up and a couple gussets cut and welded in, and then either powdercoat it or paint. Lastly, I started cutting on the old trans tunnel, and figuring out what I need to get as far as some 18 ga steel to cut and form in there. I will end up screwing it together and then the mobile welder can stitch weld it together, and fully weld then the plate that goes across, but that work didn't happen today....it was COLD and I got tired of my feet being numb. PICS:

-

😅 hopefully the only thing looking this good is the front. Ill leave the rest looking abit rougher. Really wanting to pull it out this year and at least drive around the block

-

Looking GREAT!! 👍👍 I really like the metalwork....makes you look like a skilled Italian craftsman (whereas mine makes me look like a one-armed monkey with a rock and a baseball bat.)

-

-

02-19-2026. ATLAS Z UPDATE. I trial fit the rollbar and rear tower brace, and then dropped them off to be sandblasted and re-powdercoated in "polished aluminum" which is what I had my bellhousing done in. Then I worked more on the dash, I still need to wire it, but I got all the gauges in, the dash plaque in....for the dash plaque I had to build up the back, as the hole makes it DEEP.......cardboard stacked up to the right height and glue, then silicone caulk to hold the badge on, looks pretty good I think. a 280 dash but the plaque says 260Z.....so pretty rare sight in the USA. So, you can now see how the dash will look in the car God willing. I also ordered the skillard lower piece that goes from the center down to the console and also serves as a stereo block off plate. I will be painting it matching gloss black hammertone finish, and the console floor will be that color as well. The gauges didn't go in totally as easy as the install makes it sound....I had to get inventive. Not too bad. PICS:

-

inline6 started following Need a 280zx transmission bell housing for a 240SX transmission swap

-

02-18-2026 ATLAS Z UPDATE: picked up my 1/4" thick steel plate for making the transmission mount, set out my seat belts for cleaning, and my rear strut tower brace from Apex and a Autopower Street rollbar from Motorsport Auto have arrived. So, I will decide what color I want to powdercoat stuff (gloss black of "polished aluminum") , and keep pressing forward. Will be COLD for a few days, so any work done will be indoor stuff. PICS:

-

8th build? Wow! I'm still nursing my first (and only). Car has been on the road, and off. Registered, and not. The current iteration is "not". I need help - local help - with the care and feeding of the engine. The real problem isn't with the Datsun parts, but the Chevy parts... namely getting that darned engine to work properly. Seems like a simple problem, no? But nothing is simple these days! Also, the exhaust is too loud, and the transmission is geared wrongly. I need a custom re-welding for the former, and to write a check for the latter. I also need an engine hoist and a place to work on the car. Success with hobby-cars, begins with success in real estate!

-

Jerry Mitchell joined the community

-

I agree with Mitchel. You need to decide what end setup will make you happy and build towards that. With that being said you don't need to go all out and put yourself in debt to do it. If the purist in you says you need it to be nissan powered than that seems like it should be a priority. Do some research on the VQ. There are a couple good versions and a couple that you should avoid. I'm personally not a huge VQ fan but power, weight, balance, etc, should be great in a older Z. Modern electronics make a lot of these swaps easier. companies like wiring specialties or similar, should make generic "swap" harnesses for these engines and will require little integration into the chassis wiring if your not that comfortable with wiring. ApexEngineered makes engine mounts. Transmission options aren't ideal. CD009 are strong but gearing and shifter location isn't ideal in my opinion. I got one for my 1jz swap and didn't like it so went a different route.

-

Sasquatch88 started following NA-T Charcoal Canister question.

-

The money is a big consideration but the main point is more what it’s worth to you. Do you want a particular setup and is the money more secondary, is money a primary driver, do you want to slowly upgrade or go all at once. I see a lot of people mention only the costs of the build but if somebody is really passionate about something then it doesn’t matter as much. For example the fuel injection on my ’77 280z isn’t in the greatest shape, she drives good enough but the AFR readings aren’t the best (extremely rich at idle and slightly lean at open throttle). The economical thing to do is to just swap over some triple Webber carbs, but since I would like to keep the fuel injection I decided to, eventually, slowly upgrade the fuel injection with a new ECU and a set of ITB’s. I might spend 3 to 4 times the money but I’ll have a car that I want, as I like it.

-

Dz240 joined the community

-

ATLAS Z: Sometimes, it's easier to remove the obstruction to get stuff in, then re-isntall and mod as necessary. As mentioned, I am reinforcing the tunnel and floor with a 4 inch wide steel plate from one side to the other, welded in at the door jamb on both sides, welded across the floor, up and over the tunnel, one solid weld. steel is 1.4" thick. Add a massive amount of reinforcement for the power level. When I re-welded my radiator support I did the same thing....took the time to reinforce it and make it stronger than before.......same concept your body uses when you break bone, it repairs larger and thicker. I showed the jack pick for shock value....hehe it was a last resort, and again, I didn't get UNDER it.........I had the trans on a jack all ready to go, so I just pushed it under there to it was in the well then lowered it back on to the jack stands.

-

Mitchel0407 gave you some decent advice. If it's all about the dollars, either rebuild what you have and perhaps go to a manual transmission. Next better choice would be a new GM crate engine. Small block GM engines are reasonably easy to work on and more or less stock crate engines can be had from many sources that don't cost an arm or a leg. I have had many z cars over the years with stock engines, V8 GM powered, stroked out big cam four br carbed car and a high hp, zillion dollar track car to mention a few. I sure had a blast with all of them!!! Like someone once said " if I had all the money I ever spent on Z cars, I'd spend it all on Z cars".

-

I would love to have an L28 as well, but most L28 engines I have seen are well over 200k plus miles and I’m not sure where to get parts for it to rebuild a the engine. I have seen the California Datsun L28 rebuild kit, but heard it’s not worth it. If I were to get a used L28 and rebuild, which isn’t a bad option. Where can I buy the parts for it?

-

I really like the L28’s as they have a lot of character and an amazing sound but a used VQ would also be a great option. I don’t know exactly what you would need but It may be a good idea to get a wrecked donor 350z and use its drivetrain components together with the Pro Touring or Track Attack suspension kits from Apex Engineered. That may be the easiest route if you want to go VQ or even RB (there subframe accepts loads of different engines). But if costs are a driving factor then finding and even building another 350 might be the best option. A swap done right can run you $10k to $15k easily as it’s not just the engine you need to swap but also the driveline, suspension components and electronics.

-

Swap in an L28. They're a Nissan engine, cheaper than RB and pretty easy to swap into an S30.

-

The V8 has a blown head gasket. I have always wanted to go back into a Nissan engine, but the RB's are too pricy. Would it be easier to find a used car that has everything or or find a little bit of everything from somewhere else.

-

Who's Online 1 Member, 0 Anonymous, 1578 Guests (See full list)