All Activity

- Today

-

Twin cam head for the L6 from Derek at Datsunworks

Brad-ManQ45 replied to Derek's topic in Nissan L6 Forum

I for one appreciate what Derek has accomplished, and if I had the bucks would buy it, but I really can't see it ever becoming a commodity at commodity pricing. But then, I have an automatic that doesn't like high rpm and am limited by that to 4-500 HP with a turbo - and my stock head works for that. -

No idea on the owner but wow! I would have grabbed that hatch for the history in it alone. Rare to see these in a junkyard these days as well, very cool.

-

That worked...the images posted that time no problem.

-

Skyloc joined the community

-

How did the project end up turning out? I’ve got an 86 that I’d like to do this with… just a dream at the moment.

- 8 replies

-

- electrical power steering

- electrical brake booster

-

(and 2 more)

Tagged with:

-

Fast Floridian's 240Z Track Build

74_5.0L_Z replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

Do you plan to do any chassis reinforcement? Cage? - Yesterday

-

aiden280zx joined the community

-

i edited the original post because i forgot there was s30 specific forum but i guess its fine here. I figured someone knows the previous owner here

-

@Mr.Roboto, FYI -- tried several times, and am unable to open the image(s); and it doesn't seem to be a working link either. If others are having the same issue, you'll probably need to reload. If you want to message me the image(s), I can try loading from my end. Your call...

-

MinneZota joined the community

-

My Z car log....small jobs done and fun things

A to Z replied to A to Z's topic in S30 Series - 240z, 260z, 280z

05-10-2025. I did a lot of odds and ends today.....little things put off.....I just went around and fixed as I saw them. I used the clear PPF film over the carbon fiber on the inner fender as it was getting real ratty looking on the edges. I also cut some pieces, and put it on the 2 spots the seats are showing wear from being a big guy getting in and out of the car. Will they work on Vinyl? Not sure, but I need something there. Seams showing some cracks due to my poor bodywork skills, this seals them so I can just forget about it and enjoy the car.t Tuch up painting all over the place, then vacuuming....I guess you could call it spring cleaning. I went back to a novel way of richening up the carb a little....washers under the choke know to add fuel everywhere and buy add a washer at a time I have been able to make a lot of progress on getting it right. The other way would be to buy a richer needle, but this is easy, cheap, I already have the parts, and it works. In short it was just a nice sunny day and I got stuff done. I did take A LOT of pics, so the pics I will put on here.....it's pics heavy. so you are forewarned. Cheers and God bless.~Joe - Last week

-

Fast Floridian's 240Z Track Build

FastFloridian replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

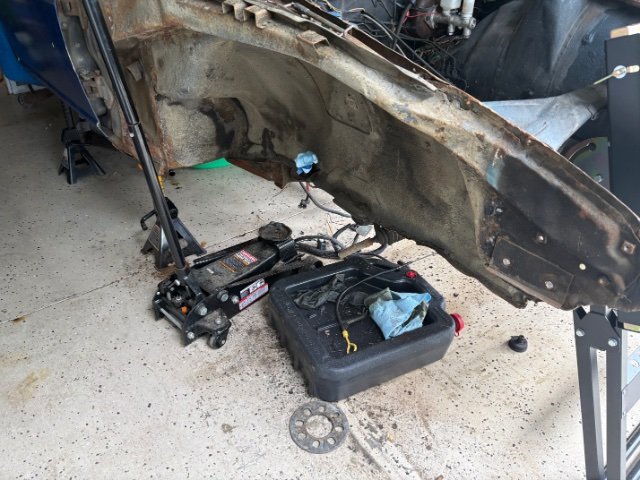

Got the front suspension and sway bar off today. Fought me a little bit, but impact helped a lot and had to take a sawzall to the toe arms, but it’s all out. -

Fast Floridian's 240Z Track Build

FastFloridian replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

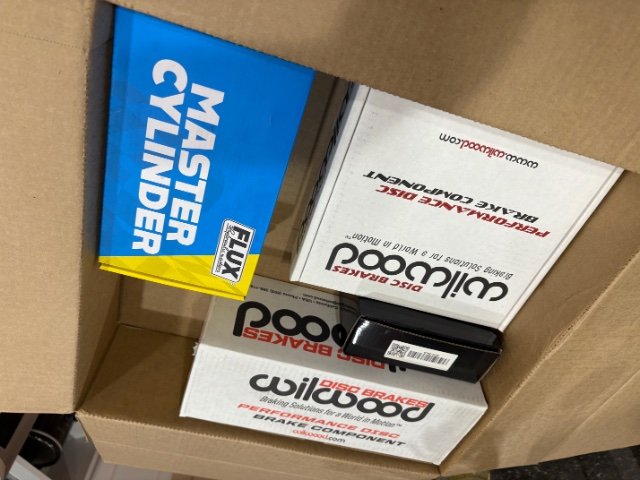

I’m hoping to get some work done on the car this weekend. So close to being done with tearing stuff down and ready to add stuff. Just got this dual master cylinder kit that I hope I can make work. It’ll let me adjust front/rear brake bias in the car. -

harrish78 joined the community

-

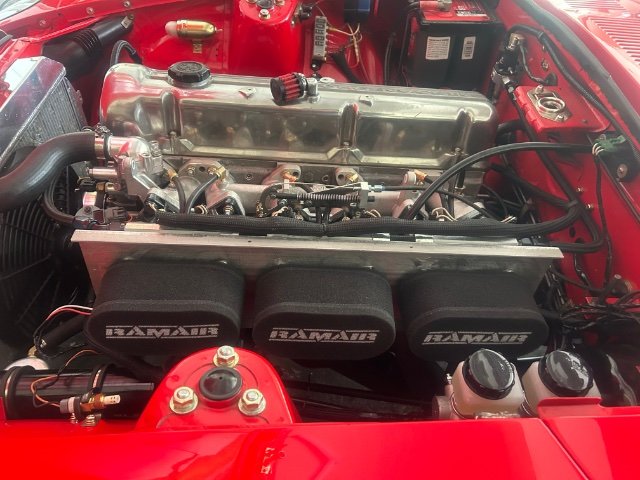

Ordered some cheaply sponge filters while I wait for my CAI box to get finished . Made a smaller vacuum log -3/4” PVC pipe . Despite having one of my widebands flaking on me I was able to drive around well enough that I wasn’t scared of dying on the road anywhere . Not much help out there for guys running MS and ITBS. Seems most Haltech or others . I’ve also got different perspectives on how to load certain tables . I have Yanni saying that all the tables can be run off of TPS and Richard that says running timing off of MAP is best . Presently I am going to try and run it all TPS . I can only hope the FAJS version of a TPS is accurate and reliable . I might eventually go with a contactless style from EFI hardware . For now I haven’t gotten past 38% TPS on my tuning so I’m not stressing my TPS to hard that’s for sure . Honestly - I didn’t think it would run even this good this early in the tune . I am trying to be patient with throttle input since I do hit big lean spots . I am also learning how to use Megalog Viewer at the same time that has a VE analyzer which is pretty damn cool .

-

pwray85 joined the community

-

Used ITBS seem to be very rare. HKS, I would stay away from the full chinese DCOE ones. KMS takes the chinese bodies and retrofits them with better butterflies and such. https://en.kms.vankronenburg.nl/products/throttle-bodies/bodies/throttlebody-twin Then there are Jenvy EFI Hardware (probably the best designed out) Throttle blades open the opposite way, tapered bore, better throttle blade angles Borla OER(I would stay away from these) ETC.... A common issue with ITB is when the engine is hot on a hot day, they tend to stick slightly open and having them return to idle doesn't work. I believe the bodies expand and cause pinching, but who knows.

-

Only part I could find was the capacitor. When I removed them from the 2 clocks I had, the one from the non working clock tested good, and the one from the slow clock tested bad. I replaced them both. Now the slow clock works and holds time, but the non working one must have another issue because it still doesn't move.

-

miloharrd joined the community

-

My Z car log....small jobs done and fun things

A to Z replied to A to Z's topic in S30 Series - 240z, 260z, 280z

05-07-2025. My custom ordered fender stickers came in. I covered them (and the rear stickers) with some PPF clear to make them permanent. -

Heavy Duty frame rails and connectors

toolman replied to toolman's topic in Gen III & IV Chevy V8Z Tech Board

Differential Installation- I had additional work on my house after painting it. Sorry again for posting delay. First, I Trial Fit the Rear Differential Support and the Cage before trying to install the Differential. The Trial Fit is make sure all the Fuel, Brake Lines and Hand Brake Cable does interfere with the Differential. Some Early Model 240Z , Nissan widened the Front Differential Mounting Bolt Holes. So make sure your Differential Mounts fit or you must slot existing holes or drill additional ones. Right Side Front Differential Mount Old Mechanical Transmission Jack for Installing the Differential and Support Frame Together. Installing the Differential- The Best Way to install the Differential is to preassemble the Differential and Differential Support with the Two 14mm bolts. This way you just have to align the Two Main Vertical Bolts with the Two Round Mount on the Support Mount. I used a old mechanical Transmission{ screw version) Jack. One person can install the Differential by himself. If you try to install the Differential after mounting the Differential Support by itself, you need other person to screw in the Two 14mm while you lift that 100Lb Differential- a difficult task. Also, early 240s with a Spare Tire Well, the well is close to the Differential Support on the Left Side Bolt and this 14mm can not even be inserted in. Some owner install Fuel Cells which are much smaller and allow the Left Bolt to be installed. The only problem with the Preassembly Way is the Two 10mm Outer Bolts in the Center of the Differential Support can not be installed with the Cage. So I drilled their internal nuts to 3/8" hole all the way thu the box crossmember. Then, install Two 3/8"x 4" long bolts from the top. Two 2"x 3" x 3/16" steel plates to spread the load over the crossmember top. Two 3/8"NC nuts under the Support Frame to complete this modification. Some people probably don't install this bolt but it is a structural part of this car. Pic of the Two 3/8" X 4" Long Vertical Bolts through the Cross Member. Closeup View Pic of the Nut inserted between the Cage and Differential Mount. Left Side View of Left Side Nut for Vertical Bolt. More Rear End Modifications coming up. -

Like Title states, looking for ITBS for 6 cylinder. 48mm preferred but show me what you got.

-

Thanks!! It's been a bit, refinding the stoke has been a challenge, but I'm getting excited again. Life changes (wife going back to school) means the race budget is way reduced this year, but I got my eye on a couple days.

-

Wow...she's looking great, Ben! Nice rebuild after that off at GTA a while back.

- Earlier

-

Thanks. Glad to see someone running something that wide. Car looks fun, good luck at your next event.

-

315/30r18 rear and 295/30r18 front. I think the rear wing is 72" wide with a 13" chord length. I wanted the wing to match the rear track width which is quite a bit wider than factory. Got the airdam painted and mounted this weekend, and finalized the splitter wire mounting positions. I have to fiberglass up the blending piece, but that should be pretty speedy once I get material. A couple photos of the mounting/airdam fixed on: I have a radiator to hood duct/extractor that i'll throw glass up while I'm at it in the next few days.

-

Looks good. What width tires are you running and what’s the width of your wing? I’m a long ways from my build being complete, but those are two things I haven’t decided on yet.

-

Who's Online 2 Members, 0 Anonymous, 391 Guests (See full list)