-

Posts

2366 -

Joined

-

Last visited

-

Days Won

27

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by madkaw

-

I left the decision with Dave Rebello. I know he can offset bore to get the most out of the block. I also went with a N42 block after reading it had the highest nickel content and a better chance of being bored higher. Maybe because of the structure of the block . He must have felt pretty confident because I told him that there is a possibility of running as a turbo with a different head . I do not know what wall thickness I ended up with .

-

Believe me - I drool about it a lot . A better inductions system would still help in the meantime

-

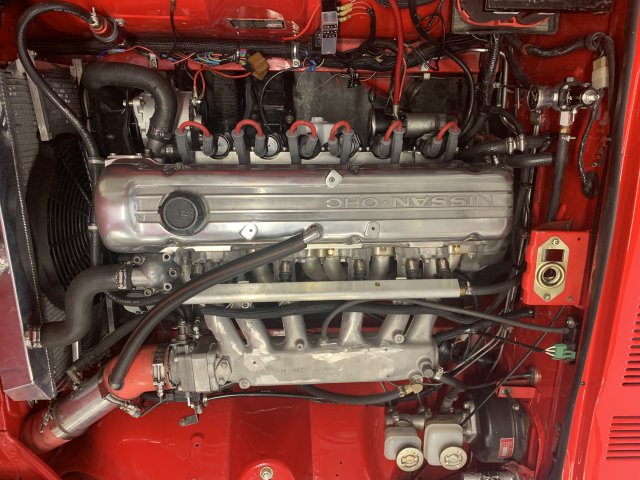

Just thought I would start another thread . This was supposed to be a L28/54 MN47 , but it ended up with a Rebello prepared N42 /MN47. The N42 was sent to Rebello and he prepped it for JE 89mm pistons . LD crankshaft offset ground with Eagle rods to get me 3.2 The MN47 head was ported by me - no flow bench , just seat of the pants cutting. Ports were only opened up to 35mm . Manely 44/35 swirl valves with bronze guides . The head is at 39cc . The cam is a 535 lift Bonk cam . It’s advertise 535 , but I could only get that with 0 lash , so it’s more like 520 lift . Engine management is a Megasquirt 3X with 270cc 14mm injectors running on a stock N42 intake with a 240sx 65mm TB . Exhaust is a MSA 6-2 header with dual exhaust to the back . BHJ damper , Kameari oil pump and chain tensioner . GM alternator 90 amps D-585 ignition coils with MSD wires . 4 row radiator with single electric fan cam sensor from 4.0 Jeep modified by me . flywheel 12lb steel that doubles for my CAS . Currently rev limiter is set at 7500 . Power drops off before then with current cam and induction .His build wouldn’t have happened except for the knowledge base on this site . Thanks for all that contributed their knowledge . Dyno session is schedule a month out . Currently using butt dyno and GPS speedo to do 0-60 times . It will also do quarter mile . Best time is 4.77 to 60 with some tire spin . Timing is 37 degrees max with a 13.0 set for WOT AFR. 7DE94C66-077D-4635-A801-2A09769EC638.MOV 8B4867CC-29D6-428F-A1D7-5F72482973E3.MP4

-

I love my 3.9 . I also like cruising at 3k because it’s where things really smooth out and I think the motor is really comfortable and no drone at 3k . Also puts me right close to power band . 0-60 times getting close to 4.5 seconds . I don’t care much about “top speed” . I am eye balling the CD to replace my G-force T-5 someday , but tired of working on the car -lol. I don’t mind altering my tunnel, my car is already altered . It would cheaper for me to get the CD vs replacing the T-5 if it crapped out. The love hate about the G-force is the straight cut gears . Love the gear noise sometimes and then sometimes I want more refinement .

-

You might have dinged Dave Rebello, he might have given out some hints on doing the diesel block properly since has done several . I think he is getting close to 3.5 liters out of his engines . I sold him my block I had years ago .

-

Getting a new trigger wheel made for my MS . Also note that I changed my dwell time on my coils to 3.7ms and it seems like it cured my #6 burn issue . Stay tuned for more updates .

-

This is what I used . I tried a laser , but it was really hard to come up with a rig that fir and sat square against the surfaces . I run the Subbie diff with a redrilled pattern on its larger yoke flange . Lots of surface to sit this on . I used a square off of the tail shaft along with this . Pretty consistent readings . i was looking for sources of driveline vibration so I wanted to make sure the lines were not intersecting .

-

Never read or seen bushing that utilized the original shells. You can’t go wrong whatever bushing you choose . I’ve been running urethane for years . Not sure if there’s much handling benefit of running urethane on the outer bushings of rear control arms . I do believe that there is sometimes some interference with the urethane flange between the strut housing and the control arms . The faces of the strut housing sometimes can be a little rough and might need to be cleaned up so the bushing flange sits square against / between the two. I just finished removing those shells the other day . It’s a battle . Take your time . Cut a slice out of the shell and then they should come out . Sometimes you think you’ve cut all the way thru and you haven’t .

-

Misfire /breakup and high rpm with stand alone AEM infinity

madkaw replied to tioga's topic in Nissan L6 Forum

Cool- I’ll try that. I was wondering if I could somehow see it on a trigger log , but they are limited on size . -

Misfire /breakup and high rpm with stand alone AEM infinity

madkaw replied to tioga's topic in Nissan L6 Forum

I keep rereading this thread because I am sure I am experiencing the same thing. At around 6700 rpm my engine starts to get louder and not smooth and looses power. This shouldn't be happening with this motor. I will get fouling of 5&6 . It will clear off during normal driving . Can't see anything during datalogging . Looks like you went different coils? looks like Audi COPs? I guess I need to go this route to be sure . There doesn't seem to be any other reason this could be happening. -

Sorry - I forgot you said you used the meter match. I might go that route too

-

Any numbers please ? Of course it probably won’t match mine , but hey- maybe it will. I’m fairly close but it still drops hard close to the quarter tank . love the GPS speedo and playing with the stop watch

-

Using a new Mac Pro -so I am challenged , but I think this is my latest tune #6 trim tune.msq

-

I only trimmed in the lower KPA areas , so we will see how it goes

-

I’m changing my laptop that I use in my car , so it might be a minute . So is it bogging or what is the engine doing during acceleration . My setting are more seat of the pants then anything . I’ve been more worried about VE tables .

-

I only trimmed in the lower KPA areas , so we will see how it goes

-

Worked good when I pulled it . Upgraded to WC so I don’t need this one anymore . Comes with shifter . No other driveline parts . Asking 500$. It’s at 47401. I can ship , but hope I don’t need to. email : sfinnerty1018@gmail.com

-

In the grand scheme of things - 70$ additional to 1000$ worth of gauges seems okay to me . Let us know Chris !!

-

Wilwood proportioning Valve

madkaw replied to grannyknot's topic in Brakes, Wheels, Suspension and Chassis

This kit I bought 15 years ago was considered a street kit. http://www.arizonazcar.com/brake.html -

One reason I bought new injectors when going EFI . Another reason I went high impedance and MS3X because it was basically plug and play . I didn’t want to chase issues over rebuilt parts . Bought OEM Bosch new that fit my HP needs . I was new to EFI - let alone programmable EFI - so I wanted as few hiccups as possible . Did you reach out to Chickenman to look at your tune ?

-

Wilwood proportioning Valve

madkaw replied to grannyknot's topic in Brakes, Wheels, Suspension and Chassis

I hate to even say because my memory is so bad . I followed the instructions and recommendations that came with the kit . I do a a proportioning valves between front a rear brakes - set up where my old parking brake was. I remember that I had to put most of the bias to the front . I run wildwoods all around . It’s not the big kit , just two puck 11” I think -

Wilwood proportioning Valve

madkaw replied to grannyknot's topic in Brakes, Wheels, Suspension and Chassis

I wish I could remember what my setting are , but I got them to lock up correctly and haven’t touched it in years . I run Wildwoods all around . I do remember that it was wayyyy biased up front . -

I haven’t got this far to try and dial it in but the single button menu is enough to drive me nuts . This sucks about the fuel gauge . Hell- the stock gauge is bad enough , but to know my new gauge might be worse really sucks .

-

Well a lot has transpired since I last posted . I had issues with the 2.8 and moved on to my 3.2 build . Thankfully with just a fuel requirement adjustment based on just a percentage increase of CC of the motor the engine fired off in the first couple of revolutions . I am 200 miles into the fresh motor and couldn’t be much happier . I finally implemented full sequential using my Jeep sensor . Only issue is a slightly richer burn on #6 cylinder. After checking everything I have to think it’s a air flow issue with my N42 intake . I am going to make a trim adjustment to the injector , though I have no clue what I’m doing . MS is not very clear on how to . It’s not enough to sweat over and going from batch fire to sequential seemed to help the issue . I have been communicating with DIY and they aren’t convinced that it’s an airflow issue . Need to get to the dyno to see where I’m at on WHP - but it’s over 200 for sure .