-

Posts

2366 -

Joined

-

Last visited

-

Days Won

27

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by madkaw

-

Running rich from a dilution of mix from the seal leak possible?

-

FPR is after the the tail . I could split the batch. I have the hot running to the fuse box , just got lazy because MS said it was okay to run all 6 with one hot. Need to get sequential going , but this should work unless the demand can’t be met with a bigger engine . I do have some kind of oil issue from a seal or something . Maybe get away with swapping intake valve guide seal on #6 will help

-

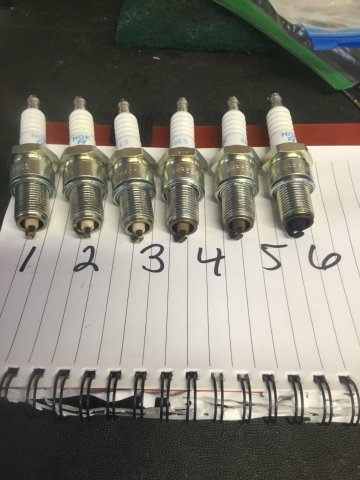

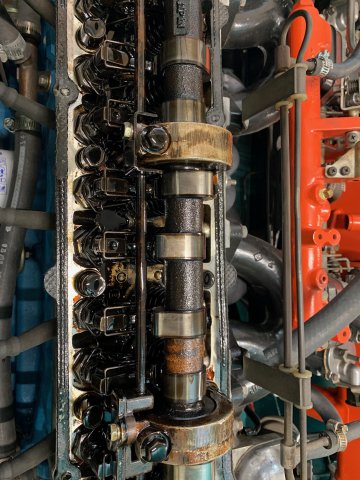

So I pulled the intake and found and oily residue lining the intake runner of 4-6 . Looks like # 6 could have a bad oil seal . Maybe bad enough to foul the mixture . The plug always looked more like carbon fouling and brushed off pretty well with a wire brush so I didn’t suspect oil . Not sure if a bad oil seal would cause my bouncy vacuum readings unless I’m seeing this as a misfire . Hopefully the guide itself is not bad . I tried a different type oil seal instead of the Ford seal and I guess I didn’t get one right . I’m assuming the color in the plugs on 4&5 is from a small amount is containment from #6 oil getting sucked over from the plenum . The pic is brand new plugs ran in a warm up cycle- I know , not the best, but car is on lift . 1-3 looks clean and is running 13-14 AFR. 4-6 get progressively worse. Valve pic is #6 .

-

Pretty sure I can the cam timing right , but maybe time to check. Not sure how I could get 225psi on retarded timing

-

Sprayed it down and couldn’t find anything

-

I see as high as 10 at 1000rpm

-

Running a stock n42

-

Well it’s batch fire and I swapped the leads between 5&6 with no change .

-

So the intake was biased forward or backwards ? So are you saying this didn’t cause a vacuum leak but caused inconsistency in the runners ?

-

Running batch fire so all cylinders should be the same . plug shows carbon fouled - dry stuff that brushes off pretty easy .

-

L28 54/MN47 Short block is fresh for the most part. New bearings , rings rebuilt head 530 lift cam megasquirt 3 - NA It’s a long story but this is what I’ve done Compression test 220 + or - 5 all cylinders . Coolant pressure test - passed leakdown - less than 5% swapped coils , plugs, wires , injectors, injectors connectors . Checked valve lash - several times checked for vacuum leaks vacuum is about 9 at idle vacuum needle bounces badly - especially at idle . It’s hard to make out a reading. The MAP gauge on MS is not that erratic , but it isn’t smooth either . Is it possible to have a bad HG and still get 225 on a compression tester? Is it possible to have a broken ring and pass a leakdown ? Is it possible for either of these tests be mute under running conditions ? I am at a loss and ready to rip it’s head off but will take any last ditch efforts and thoughts .

-

Misfire /breakup and high rpm with stand alone AEM infinity

madkaw replied to tioga's topic in Nissan L6 Forum

Okay - I am in the same boat here and I’m glad you posted . A while back I had a misfire issue that was very hard to diagnose . It was the spark plug wires were leaking and cross firing . These were genuine GM wires that weren’t very old . It took forever to figure out . Put a new set Magnacore on there and fixed it Now I have put a bigger motor in and have a high compression build I am having issues again. #6 is fouling for no apparent reason . I swapped everything possible , coils, wires, plugs, injectors - nothing helps . 225 cylinder pressure , good leak down test, good coolant pressure test . Getting ready to install a zx dizzy and wires to check to see how things go . I think these smart coils trigger to easy . #6 coil sits right above my starter . Maybe proximity is going to be the issue . If not I have a hardware problem - like piston ring ? -

Is this group buy still active ? I’m ready to pull the trigger .

-

I have a clean p79 from a fresh part out . Deck surface is flat , and valve train looks good. All the spark plugs had nice burn to them . Should be able to bolt in and go -250$ E-88 is late model with OEM valves . Looks completely stock with a good cam and rockers . Deck surface is .002 out of flat - probably be fine. 99% compete , but missing some mouse traps . Just a great core with most pieces including spray bar - 150$ shipping extra

-

L2.4 is gone and the L 2.8 is in. Time to challenge my tuning abilities .

-

Well I let this thread slip along with the build. Anyhow, it’s running with a Don Potter cam 11.25:1 CR A little vid of me driving around breaking it in.

-

Still have ECU, injectors , AFM,

-

Getting ready to install next week

-

Hard to imagine that’s Pertronix out performed LS2 coils

-

The gas smell drove me to EFI also. It worked well for me to shut the fuel off a couple of blocks from the house and empty the float bowls that way, but EFI is a better solution. Love those Jenveys

-

240z with L26 - ITBs, EFI, megasquirt

madkaw replied to nmehdikh's topic in S30 Series - 240z, 260z, 280z

Looking great -

It looks like you have all the ingredients to whip up some good power . I’d see what a 3” down pipe could do for you . It might change more parameters than you think. Do you run a knock sensor or did they have one at the dyno?

-

No experience with turbo builds , but from lots of reading here it seems that the very first things the guys do is the down pipe increase. You have invested a lot of money in forged pistons and other goodies , but you are choking all your investments with a tiny exhaust. Timing might also be a victim of your small exhaust. Don’t want to build heat by bottle necking flow. What was your timing at?What was your AFR’s?

-

Did P90 heads come with steel/chromemoly valve seats?

madkaw replied to scartail's topic in Nissan L6 Forum

P90 had steel seats already. Only heads that had brass were very early heads