LLave

Members-

Posts

762 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by LLave

-

I actually have some I just took off my 260Z, calipers, rotors, brake line. They have been sitting for a few years and have a little rust. Yours for a six pack.

-

GLWS. If I wasn't so far along I would buy this... and probably many dollars ahead.

-

Buy one on craigslist and practice. Gas is required don't mess around with flux core. Or.... make a friend with a welder. Additional thought... I would give some serious consideration to how beneficial stitch welding you chassis will be. I did mine where I was already doing repairs, a "while I am in there" sort of thing. But it's a real pain in the ass. Stripping undercoating, paint, seam sealer, cleaning out the joint. Welding, screwing it up, grinding it back out and then rewelding. If you don't already have the skills and equipment, I would focus on other a parts of the build while you acquire skills/equipment. I don't mean this to be discouraging, just saying, don't over focus on a "need" to stitch weld your chassis.

- 10 replies

-

- entire car

- mig welder

-

(and 3 more)

Tagged with:

-

Impressive. It really goods great. I like the color combo

- 17 replies

-

- Cook racing

- Jim cook

-

(and 1 more)

Tagged with:

-

Heavy Duty frame rails and connectors

LLave replied to toolman's topic in Gen III & IV Chevy V8Z Tech Board

Nice work! I love that advanced spay can technique. Painting the inside of the cowl is very difficult. -

TrackZpeeds CXRacing LS1 T56 240z

LLave replied to trackzpeed's topic in Gen III & IV Chevy V8Z Tech Board

Jim, I live in Santa Rosa, where we just went through major fires. I also have family in Redding. This is very close to home. I am sorry that you are going through this. If I can help let me know. You are about 4 hours away, but I will show up with truck and trailer should shit hit the fan. Stay safe. -

Great work. Thant looks really good. Bookmarking for future reference.

-

HybridZ THER IS NO BEST I really like Hokes kit. I ended up building my own for some reason... It seemed like a good idea at the time. I enjoyed the challenge and freedom, but really if I did it again I would just buy his kit. Hah.

-

Love it. That LSA must be a tight fit under the hood!

-

New Front End Alignment - Not what I was hoping for

LLave replied to jgkurz's topic in Brakes, Wheels, Suspension and Chassis

No direct tech to add, however I did save this snippet from the great John Coffey "" I get this question daily. Assuming you've spent money and time building adjustability into your suspension AND are willing actually adjust then these recommendations make sense. Otherwise, take the car to Pep Boys, tell the tech to "Make it all green", and hope your tires last a long time. Track/AutocrossFor 225 to 245 width radial DOT tires try these alignment settings:FrontCamber: 3 to 3.25 negCaster: 6 to 7 positive (even on both sides)Toe: 1/8" to 3/16" outRide height: 5 1/2" to 6" measured at the front of the rocker outboard of the pinch weld seam.RearCamber: 2.5 to 3 negToe: 1/16" to 1/8" inRide height: 5 3/4" to 6 1/4" measured at the front of the rocker outboard of the pinch weld seam.For tire widths over 245 try these alignment settings:FrontCamber: 2.75 to 3 negCaster: 6 to 7 positive (even on both sides)Toe: 1/16" to 1/8"" outRide height: 6" to 6 1/2" measured at the front of the rocker outboard of the pinch weld seam.RearCamber: 2.25 to 2.5 negToe: 1/16" to 1/8" inRide height: 6 1/4" to 6 3/4" measured at the front of the rocker outboard of the pinch weld seam.StreetFor 225 to 245 width radial DOT tires try these alignment settings:FrontCamber: 1.25 to 1.5 negCaster: 4 to 5 positive (even on both sides)Toe: 1/16" out or 0Ride height: 6" to 6 1/2" measured at the front of the rocker outboard of the pinch weld seam.RearCamber: 1.25 to 1.5 negToe: 1/16" to 1/8" inRide height: 6 1/2" to 7" measured at the front of the rocker outboard of the pinch weld seam.For tire widths over 245 try these alignment settings:FrontCamber: 1.25 to 1.5 negCaster: 4 to 5 positive (even on both sides)Toe: 1/16" out or 0Ride height: 6 1/2" to 7" measured at the front of the rocker outboard of the pinch weld seam.RearCamber: 1.25 to 1.5 negToe: 1/16" to 1/8" inRide height: 7" to 7 1/2" measured at the front of the rocker outboard of the pinch weld seam.Caveat Emptor: These are starting points for you and your car. Be ready and willing to change them based on your preferences and local conditions. These alignment settings might be a bit tricky in the rain and even trickier in snow or ice. Your tires will wear a bit faster then the stock alignment settings. If that's a concern of yours, stay with the stock numbers and don't ask me dumb quesiton like, "Well... how much faster will they wear?" or "How many miles will the tires last with the Track alignment setting?" If you're asking those questions you shouldn't be reading this thread. Go buy a Honda... "" -

TrackZpeeds CXRacing LS1 T56 240z

LLave replied to trackzpeed's topic in Gen III & IV Chevy V8Z Tech Board

Car is looking great! -

Thanks man. Upgraded OEM is sort of what I am going for.

-

Closing the loop on this one. I finally got this all sorted. I ended up with 2004 WRX seats, modified to fit in the Z while retaining the adjustable height mechanism on the driver side. I picked up a set of Wesco roadster retractable seat belts. Designed and built a little mounting pad on the rear strut tower. Seems to all work pretty well. Mildly interesting pictures:

-

TrackZpeeds CXRacing LS1 T56 240z

LLave replied to trackzpeed's topic in Gen III & IV Chevy V8Z Tech Board

Nice! I can't wait to get mine painted. I just need to find someone in Norther CA to paint it for a reasonable cost. -

That jig is the way to go! Can I get on the jig loaner list? I haven't welded mine yet.

-

ANOTHER Datsun Z/LS3/T56 Swap Thread

LLave replied to Ironhead's topic in S30 Series - 240z, 260z, 280z

Nice! I was somewhat close on my wild guess. Many many pounds of force. That is not my car, another members here. I can't seem to find the original thread but check it out here: https://www.diyauto.com/manufacturers/nissan/generations/240z/diys/differential-cv-lsd-hp-torque-r160-r180-r200-r230-diff-mount-faq-by-jmortensen -

ANOTHER Datsun Z/LS3/T56 Swap Thread

LLave replied to Ironhead's topic in S30 Series - 240z, 260z, 280z

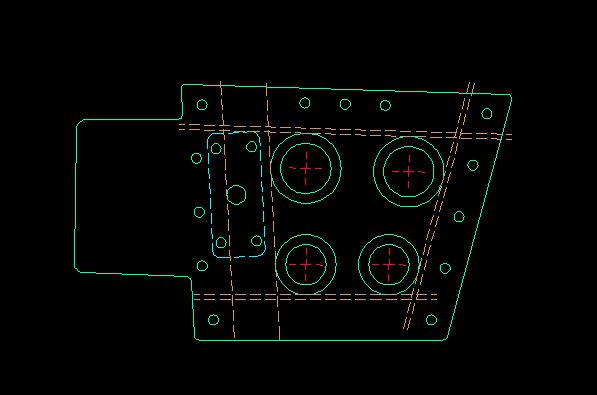

Making that double sheer would certainly be stronger, but like you said it is likely overkill. I would however get a larger diameter thick washer on the top, large enough to support the whole bushing. Like this: Then, where is going to go? It's not going to bend that mount, you could pick up the whole car from that mount. The diff would have to sheer the bolts, which for 10.9 M12 is like 15,000lbs or something (Someone will correct me I am sure) -

Just saw some on Ebay right now, rebuilt and painted up. Not my listing. search "83 Datsun Nissan 280ZX Turbo Half Shafts-Axles-Prepped-Painted"

-

I think I have a set in storage. They need a rebuild though.

-

That's exactly how I have been feeling! Hah. If you are going to be loud, you had better be able to back it up. No reason for a 300hp car to sound like a top fuel. I mean to each their own, i suppose.

-

Maxima rear brakes and 280zx MC

LLave replied to 383 260z's topic in Brakes, Wheels, Suspension and Chassis

Did you bench bleed the master cylinder? Air bubbles can be really difficult to get out if you don't bench bleed. Have you checked for vacuum leaks at the booster? Sounds like you may also have a leak, or a bad booster. Also, check the booster / reaction disc. It may be that the disc fell out. -

ANOTHER Datsun Z/LS3/T56 Swap Thread

LLave replied to Ironhead's topic in S30 Series - 240z, 260z, 280z

I think you will be just fine with bolt in. How do you plan on routing the fuel lines? Through the cabin? -

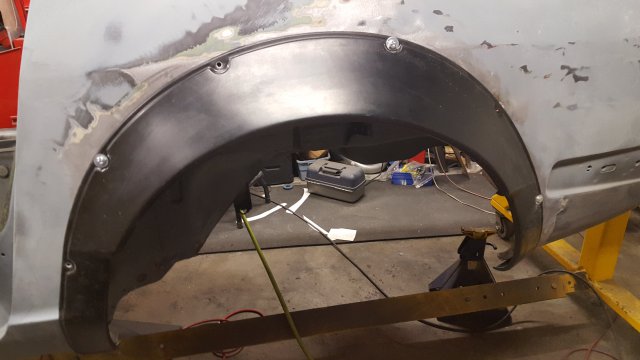

Better late than never, I suppose? A few points The mock-up wheels are way too big (18s) but they are what I had on hand at the time. The garage is terribly messy. I am an amateur and have no idea what I am doing.

-

I think your flares look great. Subtle enough to not change the lines of the car drastically.

-

I asked them about the 260 back in late January. They said that a few prototypes had been made but nothing official yet. Cost around ~$800