-

Posts

1155 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by John Scott

-

Will a JTR trans crossmember work for T56?

John Scott replied to auxilary's topic in Gen III & IV Chevy V8Z Tech Board

So, different than this, Dat-106? You're not referring to the R200 crossmember? If not look past the rear end crossmember, and the driveshaft loop. -

Will a JTR trans crossmember work for T56?

John Scott replied to auxilary's topic in Gen III & IV Chevy V8Z Tech Board

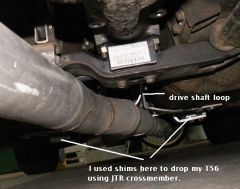

I used it on my 240 + T56 (gen I) . I shimmed my crossmember with aluminum plate to sit about 1/4" lower for driveline angles, added another layer of sheetmetal under and biggest washers I could fit inside, slightly bent ends to fit floor. Took a fair amount of beating for clearance. Other piece is driveshaft loop. -

I have two local friends that didn't have the right wife/car mix and now spend endless hours without complaint in their garages and track. Of course they sleep alone.... As long as you devide your attention right, you'll get used to the comments. 27+ years, they get harsher, then mellow out over the years. Congrats on the first drive! Most don't realize what a huge accomplishment it really is.

-

Wish me luck...at the dyno..

John Scott replied to 280Zone's topic in Gen I & II Chevy V8 Tech Board

DA is a bugger considering thin air. Here, day starts at 7000, fast times for all...then will reach over 9000 by late afternoon. Often sees over 10K. Gotta figure it into the equation or you can get real bummed with hp figures. -

Sorry, I think the atf probably has some merit, just being sarcastic. I've used it in the intake to free up some stuck rings, years back. Also heard it helps seat some rings in unique situations, synthetic oil etc. In the meantime I'm taping on a few more magnets, and regarding mothballs, they're getting harder to catch.

-

Don't forget mothballs in the gas tank trick, magnets on the fuel lines, swirly spinners on your intake. Up to 750 hp with 85 mpg increase!

-

Its painted, heated, lots of windows looking over yard and beautiful gardens. Vacuum, light dusting, few times a year wipe down. I don't keep it too clean as I like to have a place where the kids and I can do no wrong with projects. Lately it has the characteristic smell of a classic 75 year old garage with the strong overtones of 90W and gasoline mostly due to a recent differential swap and track day. This evening I went out and worked on resetting the carb for our much lower altitude events. Started it up, purred like a tiger. Ahhhhh, dust, oil, burnt gasoline. I inhaled deeply..... and loved it.

-

Help...240z swap sbc header problem

John Scott replied to datsun71's topic in Gen I & II Chevy V8 Tech Board

Also choosing a good high temp silicone 90 degree boot adds to clearance. This is what I use with my straight plug (AFR) heads MSD -

Why am I constantly being asked to abide by posting rules?

John Scott replied to Brad-ManQ45's topic in Site Support

nevermind.. -

Old post, but I'm at the last of my tread. The Nittos have held up really well, great cornering. Best bargin I've ever hit. Last week I had a 1.70 60' @ 16 psi tire pressure, relatively light launch. Pretty good for an old 7 year old 225 tire. I'm sure next time out I'll get high 1.60s, but I need to think about the next set of tires. I see 245 50 16s are the only size I could now consider for the 16 rim. I still have stock spring perches, but running Arizona Z car springs, stock height. I am also used to the characteristics of the Nittos and am not selling my soul to the drag racing gods, perfectly happy with cornering well, good milage tire, a stiff suspension and hitting 1.6s. Anyone confirm the fitment of 555s 245 50 16s on a stock height suspended 240? Wheels are Centerlines, 16 x 8s, 4" offset. Thanks!

-

Wish me luck...at the dyno..

John Scott replied to 280Zone's topic in Gen I & II Chevy V8 Tech Board

Just an idea, but go to any 1/4 mile track, take your (trap speed X .00426) X (trap speed X .00426) x (trap speed X .00426) X weight. It will be approximate of a typical dynojet..weather conditions, altitude make big differences...The good thing is you also have an actual measurement with the car rolling down the road, not a controlled dynocell. I'm guessing low 300s, 325 for a number. Dyno'd on the stand is worlds apart from living in a Z engine compartment, exhaust compromises, heat, airflow. Good luck and hope you get more than you hoped for. -

After I installed I can say mine is somewhat quieter than my open end... due to ?? Maybe my gears found a happier place with the OBX, backlash was slightly less than original where I had a touch of gear noise on float conditions. By silent, I mean the LSD is making no additional noise to indicate it is present. Of one 180, two r200s, the current set up with the OBX is the quietest. I am running all poly mounts, R/T and stock mount, as I was with the open end. I guess it is all relative to what you are used to.

-

Just an update. Really cool day on Wednesday, so dialing in my carb was really fun doing long third gear roll on burnouts. Spent a good part of yesterday at a private track day. Endless runs. OBX stood up to countless clutch drops, 2nd gear burnouts warming the tires. Took it for a nice weekend drive this morning. Still absolutely silent, working like new. My 60' times are down 2 tenths from the open end, best of 1.701 getting real close to 1.6s. imo not an easy feat with a torque-y 383, and relatively skinny 225 50 16 tires. So far so good. Anyone local wanting a ride to experience an OBX personally, let me know.

-

With photos of Holley 4150HP, Vic Jr, Phenolic 1/2" spacer, K&N 3.5 X 14" filter, Ricks first generation http://www.firstgen.com # EP-102 base. I used modeling clay to verify clearance to hood. Side View: Carb Base: Carb and 1/2" spacer: Using clay to verify clearance: Front: Middle: Rear: Inside closed hood: Front: Middle: Rear: Should have kept my 4" filter!

-

T56 hard reverse

John Scott replied to lgoodson@pacbell.net's topic in Gen I & II Chevy V8 Tech Board

Appreciate the additional info. Guess I'm comparing to some solenoids like line locks etc, that are only to be used short term. Nice to know these are more robust. I suppose mine will last forever I know its a remote chance, but wiring to brake switch, anytime you use the brakes. lets say flying along at 150 mph in 6th, reverse gate is open. The extra fidgeting insures a conscious action. -

T56 hard reverse

John Scott replied to lgoodson@pacbell.net's topic in Gen I & II Chevy V8 Tech Board

The solenoid should only be used when you put into reverse. Having it on all the time would surely burn it out, and why activate it every time the brake is on? Sometimes I sit for a long time at stoplights or drivethroughs around here. I wired a micro switch near the knob, you can even get knob with button on it to activate. Gate is spring loaded so you can "crash through" if power fails. This also satisfies some NHRA ruling for having a revese lockout switch. Sure you can de-activate the whole works, but I kind of like the fact I can't accidently shift into reverse. -

I have probably the least amount of differential experience, but willing to state my opinion on using 8, 0.062 Mcmaster washers and feel break away torque has little to do with torque biased diffs. This isn't a clutch type diff. IMO I think they're too thick, especially using 8. The action depends on the twist rate of the helical in the side gear. The washers offer a touch of axle preload and keep things quiet. I've put a few hundred miles on mine over the last few days. Pushing hard in corners, and lots of drag style clutch drops. I want to confirm its going to be reliable when I take it to the track. Still completely silent, working perfectly, only noticable when you need it. Anything goes wrong, I'll be the first to post. I hope others are putting theirs to the test and will chime in. Re: jmortensen below: Anyone able to point to information on needing more preload and adjusting break away torque in a Quaife or OBX, please post the link. If spinning the inside tire on corners with high hp cars were a regular problem, wouldn't there be more posts on the internet and Quaife, beign a reputable company would have addressed it already? Maybe new ones come with stiffer washers?? I searched for days before assembling mine and never found anything except John's old post without any followup results. Surely John Coffey and some Viper(?) weren't the only ones experiencing the problem. There's got to be 1000s of other high hp cars racing Quaifes with no apparent issues. Possible incorrect assembly, too few or wrong type Belevilles, from Quaife? I'm not doubting the potential problem, but if it is common with Quaifes running in high powered Zs, Vipers, other, wouldn't it and the solution be posted all over the internet? .........VVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVVV........

-

Hey Grumpy, thanks again for fielding all the questions. Question: I have 383, isky solid roller, 244 385 lobe lift, 108 degree, afr 195s, vic jr, srp flat tops, figuring about 10.6:1. In past I've run a 4150HP 750, but had to jet it down nearly 8 steps in rear, three in front to get it running right. 1 3/4 header shorties, dual 2.5 into single 3". Track is nearly 6000', DA usually 8000+ in summer. Confirmed by plugs and afr gauge running WOT. Today I threw on an old Speed Demon 650, which hated my cam duration, so I reconfigured with all bleeds, orifices to a Drag Race Demon specs, smaller IFRs, larger low speed bleeds, etc, dropped jets down 3 primary, 2 seconday, add notched float, jet extensions, put a big old honkin' squirter on the primary side. The mixture is finally adjustable and the engine is now running better than any carb'd car I've had, idles great, razor sharp at all rpms. You'd swear it was FI. I'm running the same secondary jet I was in the 750, with a dead flat 12.4 at WOT. I know I have a better signal and velocity with the smaller carb, but seeing how far down I jetted the 750, would a 650 be losing any hp specifically mph in 1/4? A simpler question would be how much hp can a 650 carb support? Thanks!

-

Dude, this is a Vette 327.... crunchy, of course. Doc is it fuel injected?

-

Probably different output shaft and rear housing. I did this on my first 700r4 out of a 4x4. Best to search google.

-

Just called him and offered $113 and a mostly full bag of Cheetos. Told him I'd pick up today...He'll be calling you. great find! FI?

-

I don't think we need to go that far, though in the end it might be a more refined solution. The belevilles, when applied correctly, offer a reliable and inexpensive solution. I don't believe OBX has any engineers or ongoing testing, thus the random assembly of the washers. Since the OBX design seems to be sound, except for the low quality of the original belevilles, and random assembly errors, someone with more brains than myself needs to figure out which belevilles and how many offer the right force and deflection with regard to the movement needed. I think Quaife uses the belevilles effectively using a fair amount of deflection to preload the side gears, allowing movement, without exceeding the spring capabilities of the washers. Again, these are probably here to quiet the operations, not provide a bunch of force on the side gears. I can't see where axles coming together, stressing the washers to the max will have any long lasting positive results.

-

Yeeeehaw! First drive. Right off I can say the rear is quieter than my original set up where I had a some subtle gear noise, especially at float. My car's exhaust is really loud, so in perspective now I notice no noise what so ever. Happy to call it beginners luck. I am using the RT and stock mount in combination. Did quite a few lock to lock circles, no clicking, popping, grabbing. I'm not a track racer so little experience, but all I can say is leaning on the throttle allows a very linear oversteer. I've had some clutch LSDs and they tend to kick out as they lock up. Not so here. Absolute blast to power out of corner with force I've never been able to put down before. Also my 383 develops a fair amount of torque, so roll on burnouts are easy. Two nice even and loooooong black lines. Most of the OBX gripes have been due to washer failure, it will be interesting to see which washer configuration is going to last. So far so good. Too early to say anything else.

-

Finally received my side bearings, 30209-C from Autoparts Giant...lots of online complaints, use with caution. Used the oven (200 degrees)/ freezer method for ring gear and bearing install. Overall, OBX was slightly wider, end to end, but from bearing mounting surfaces, came out nearly identical to the original carrier. Using original 3 shims, backlash is slightly tighter than the original .007+, now sitting right at .007. Stubs popped in, fluid filled. Getting a nasty cold. So stopping for now. I'll update when I can throw some power to it.