-

Posts

3916 -

Joined

-

Last visited

-

Days Won

6

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by cygnusx1

-

On another note: By replacing your intercooler with a length of pipe you drastically reduced the volume of your intake tract. Air is less likely to setup low frequency vibration (flutter) in a smaller volume. In effect you changed the resonance frequency of the system. So attributing the flutter ONLY to intercooler restriction is wrong. You also have a much quicker dynamic response to pressure changes in the system which will certainly change the way the BOV "dances" with the compressor and the throttle plate.

-

It would be better, efficiency-wise, to get a boost controller that will dump exhaust through the wastegate when intake flow has peaked. Dumping compressed air is wasted energy (somewhat). Basically, a less aggressive boost curve via wastegate control at part throttle...if that's possible. I just drive around the issue on my car, but I'll try loosening my BOV spring and just letting it vent. It's cheaper and easier than either replacing the turbo or installing an expensive boost controller.

-

I ran into the same thing tonight. I tore a 14mm Ford o-ring while re-installing my fuel rail. The O-ring measures 14mm OD and 3.5mm width. Not a common size at all. I am going to visit Ford tomorrow to see if they have any. The injectors are Ford Lightning.

-

Looks like that stock fuel rail and lines are good for more than people give credit for!

-

Jon, it's not the wheel, it's the inner CV joint moving in/out relative to the diff case.

-

Old thread and yes the diff has held up with all the clunking, however it is getting worse and I noticed some play in the right side output hub. With the car on the ground and in gear, if I roll the car forwards and backwards, the right hub shifts in and out along the axis of the axle about 1/32" thus making a clunk. It looks like this is where most of my clunk is coming from. I've got all the external sources of clunk tied down pretty good. Any idea why the output hub would want to thrust in and out of the diff under forward and reverse torques? I run 280ZX Turbo CV axles. I am going to have the drivetrain out of the car in a month or two for the Z32 trans swap and want to get ready if I need diff work also.

-

My turbo never fluttered until I switched to MSII, and got rid of the AFM and about 4 feet of corrugated plastic pipe with a cheap air filter. Once I went with a large cone air filter directly on the compressor inlet, I got surge at part throttle over 3000rpms. My thought is that the turbo moves that much more air now with the free flowing intake that I cross the surge line. I run a TO4B "Super-V" trim and a T3 turbine through a decent sized intercooler.

-

All I know is that I have been playing for a week and I am down about $120,000 but: 1) I bought A LOT of really low prices, even though they didn't bottom out yet they will come back. 2) It's not real money 3) If you want to know which stock will drop, ask me what I just bought. (there is some value to being able to consistently pick losers...I think.) if you want to add me to your friends list I am "fastZcars" at updown.com

-

Mine was mostly repaired before the dawn of the digital camera age...but here is some recent fools gold I found. I cut out the bad metal, coated it with POR15 and riveted on the plate with a sealant behind it. This aluminum plate should keep it back for a while.

-

Azc Brake Kit Tech Tip

cygnusx1 replied to arizonazcar's topic in Brakes, Wheels, Suspension and Chassis

GET YOUR ROTORS STRAIGHT FROM DAY ONE I had much success with ordering 0.001" and 0.002" stainless steel washer-shims from McMaster.com. You need a dial indicator with a magnetic mount or any mount that allows you to clamp to the strut tube, a magic marker, and bags of shims. It takes patience. Here is what I did... HAT *Clean all rust dirt grime off of the hub. *Run a dental pick in all of the fillets to get out the grit. *Mount the aluminum hat to the hub and torque everything to spec. *Mount the hub onto the spindle and torque to spec. *Place the dial indicator on the inside surface of the hat, where the rotor mounts to. *Establish ZERO, clocking to one of the four hub bolts that reads off (outwards) by the most. *As you turn the hub, get a magic marker and write down the dial indicator reading at each of the four bolt location. (the base one will be zero) *Remove the hub from the car and the hat from the hub. (mark the hat so it goes back on clocked the same way it came off). *Add shims to any bolts that were reading off by more than 0.002" or so. Add the amount of shim equal to the number you wrote from the dial indicator, err on the thinner side. *Reassemble, torque, install, take more readings with the dial indicator. *Repeat until you see +-0.002 difference at all four hub bolt locations. *Ignore any dips/peaks on the aluminum hat that happen in between the four hub bolts, as long as they are under about 0.005". (if more, you need to surface the hat and hub assembly on a lathe.) NOW you have a true, straight place to mount a new rotor. You should never have to do this again, although it doesn't hurt to check it when replacing the rotor. ROTOR *Install the new rotor. *Check for runout at the center of the swept area with the dial indicator. *If it's less than 0.003" you should be good. If it's more than 0.006" you may feel it in the steering wheel and should have the rotor lightly cut after a few heat cycles. TIP: if you really want to, you can try re-clocking the rotor on the hat to get better results, but this is a longshot. NOTE: If you have to shim anything above 0.010" or more, you should be looking for a machine shop, or new hubs. Here are the shims I used for the four hub bolts: McMaster Part Numbers: 98126A126 18-8 Stainless Shim 1/2" ID 0.001" thick (10 per pack) 98126A168 18-8 Stainless Shim 1/2" ID 0.002" thick (10 per pack) http://www.mcmaster.com/ Based on my experience: You can't feel 0.003" but you can feel 0.010" heavily in the steering wheel. An additional beneft of having little or no runout is that the pads remain nice and snug to the rotors. When you hit the brake pedal, the brakes are "right there". As a matter of fact, after I did this, I needed to back off my brake light switch. The pedal travel was reduced enough that my brake lights would only come on under medium braking or harder. -

Glad I could help.

-

Nice job. You will definitely be tweaking that setup to get it right after your first test drive. It looks like you have left plenty of room for modification and further adjustments later on. Trust me, you will be yearning for more PSI within minutes of the first few boosted drives.

-

No. The vapor should all be contained in the tank and hoses. Those grommets are "weather seals". They will allow EXHAUST GAS into the car and FUEL VAPOR into the car only IF the fuel vapor is escaping from the tank somehow.

-

You need to look at the timing that MS is screaming at you with that HUGE number in the trigger wizard and confirm that number on the timing pulley with a timing light (with the engine warmed up). The trigger angle number should be adjusted until the BIG number and your pulley marks agree under a timing light. Mine was -60 when I used the 83 dizzy but yours could be different...I suppose. Dont worry about the number. Just make sure the MS# matches the pulley.

-

Very tasty dyno sheets...you make me want to add another 5psi to my motor. It's just a few turns on a little screw. Would you consider your timing of 18deg@15psi to be conservative? I set mine around 22deg at 15psi, but then again, I don't spend a ton of time at 15psi either. Maybe I should back off.

-

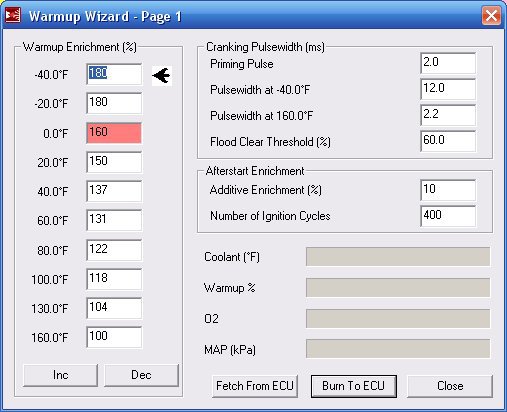

Are you talking about warmup enrichment? This screenshot is from my MSII with B&G v2.687 firmware. I have tested it down to about 20deg F.

-

New 280z owner. pics inside. please comment..

cygnusx1 replied to 77LS-Z's topic in S30 Series - 240z, 260z, 280z

Looks good from here. The motor color even matches the car! Should be quick when it's all done. Welcome to HBZ. -

DIY 180 Degree/Single plane/Flat plane V-8 crankshaft…

cygnusx1 replied to BRAAP's topic in Powertrain

What would it take to scour up a Ferrari crank out of a wreck? I am not sure about the costs but it might be worth starting with what already works. I think I might already know the answers to my question. I also have dreams of hoggin out my own car from a chunk of billet someday. I bet if you can contract up a company to make a few hundred flat plane cranks for the SBC, you might have some customers. It would be the perfect motor for some of the HQ kits and replicas out there. http://jalopnik.com/5041611/ferrari-360-modena-v8-engine-on-ebay-has-us-daydreaming Here is a Ferrari "chop shop" http://stores.ebay.com/T-RUTLANDS_W0QQssPageNameZstrkQ3amefsQ3amesstQQtZkm -

Great house! Lots of people up here just North of NYC were over-sold mortages five or six years ago. We have 5 year old, 6,000sq-ft McMansions all over the place that look abandoned and overgrown. We almost ourselves got rooked by the banks when we were trying to decide between a move to a larger home, or an extension. The banks hooked me at first by waving McMansions in my face, but I fought back with simple math and decided to pick up my hammer and saw to double the size of our little home myself. Glad I did. I got away cheap and still have a modest home we can afford on one salary. Good luck with the home and I wish I was close enough for the house warming party! Now go get some firewood and save the oil/gas bills for the Z.

-

Wow that's almost exactly what happened to me about two months ago. I now have EDIS-6. I was told that the dizzy's pickup electronics tend to fail as they get hot and then work again after they cool off. That's a sign that it is failing. You can get a new dizzy for about $250. My tach would start swinging around like nuts while driving and shortly afterwards the car would just shut down for 20 minutes or so. While trying to restart, the tach would go bonkers until it cooled off. It happend to me twice in three years. I decided to get away from the dizzy and so far so good.

-

I can't fathom what the R200 and half shafts are thinking. Amazing!

-

Phil, just got a curiosity thing...called....um.....I can't remember....oh yeah a question! I also have the Sportmax wheels on my 280 but they dont seem to stick out anywhere nearly as much in my stock flares as yours do in the ZG flares. Are you running wheel spacers to set the wheels out more or just really fat tires? Rear bumper finishes it off nicely and the un-cut airdam is nice.

-

Yup, thanks Val, but I think that the pulse from large, batch fired, injectors is so far away from the fuel pump that the factory damper has little to no effect on the pressure wave resonances. Paul (BRAAP) also has a dead head fuel rail as I recall. Paul, are your injectors batch or sequentially fired and do you see pressure "vibrations" at the rail?

-

My hunch is that because so much of the wiring and assembly is open to the user's skills, there is lots of opportunity for error in installation and wiring.

-

I know Alfa Romeo used the Hemi head design as early as c1915.