-

Posts

445 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by 1969honda

-

Ordered the gold pickup box today from 440source.com, rep said it measures 1.75" tall by 3.5" wide on the side the port is on and 4" on the non port side. With the port it should be about 4" x 4". Once it gets here I've got a plan to cut the stock pickup and either tap or press fit a fitting in (and tack in place). Then I'll bend up a new 3/4" tube to attach the box and finish my sump baffles and a baffle plate across the top above the pickup.

-

Check post #1251, he might have some answers for you on the v12 http://forums.hybridz.org/topic/50042-250-gto-owners-thread/page-63?do=findComment&comment=1192383

-

Getting back to it. Working on the Z again.

1969honda replied to AkumaNoZeta's topic in Fabrication / Welding

But then what will they do for a left hand thread! -

That pump still appears to have a removable pickup so a rear sump shouldn't be too hard Look into remote oil pump pickups and other milodon/Canton/etc oil pump pickup tubes.

-

something like this? https://www.rodshop.com.au/bellhousings/holden-rb30/bh084a-gm-manual-bell-housing.html there's also this option, https://www.rodshop.com.au/bellhousings/holden-rb30/bh84sp-special-bell-housing.html

-

The other question to ask is how much chassis with do you want to do? The v8 will definitely create more torque and require additional chassis stiffening and reinforcement over the 2JZ. I love V8s, but a straight 6 turbo or NA with high rpms would definitely be fun. Just more food for thought.

-

I've played with it a little, really need to study out the air flow requirements for my power goals and go from there. I could easily big single it and hit 600+, but I want it to spool pretty quick and be a little street friendly. Can't have your cake and eat it I know, a small amount of lag will definitely help with driving it on the street, but let's be honest, racecar...

-

Yeah week have to look when I get back home at the end of next month

-

Yeah I want to try a screen on the crank and in that video I emailed you can see a crank scraper as well. *edited to correct phone auto correct errors

-

I'm thinking if cutting if and tapping/welding a -12 AN fitting where the sump starts, then centering the pickup box in the sump with a couple hinged baffles. I made a cardboard template to put a baffle plate across the top of the sump as well to help with oil trying to flow forward as well. As for windage screen there isn't one, I figured some milodon screen material or something from Ipaco should work. I have pictures from a buddy where he just had someone change the pan to a front sump and created a windage screen. I'll find them and attach them.

-

So I'm kind of bouncing around on focus right now, but I'm also away from the car so my mind is wandering. I've got the bellhousing ordered for the transmission, feelers out on a couple different flywheel clutch combos, most the parts and design figured out for a rotisserie and today I think I finalized plans for the oil pan sump and pickup. I got most of a baffle plate to keep oil in the sump figured out before leaving home today (sorry forgot to take picks of the C.A.D. template), and I sent 440source an email about a couple pickup screen boxes they make. The attached picture shows two options they offer at very reasonable prices. If the steel one will fit in the space I measured I should be able to modify the pickup and use a combination of AN fittings and 3/4" tubing to hook it all together. This should allow me to ditch the stock lower steel oil pan, gain about 3-4" ground clearance, and put some baffles around the pickup. The attached oil pan photos are not mine but show pretty well what I'm dealing with. The last picture shows the stock cast-in pick up tube from the under side of the pan, it actually runs all the way to the back of the block and is closed off on both ends with freezer plugs.

-

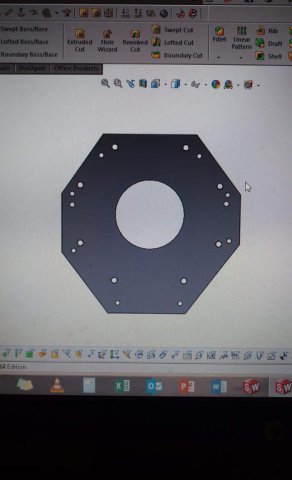

And this is on the way, should get here while I'm gone to school and be waiting when I return. If the transmission holes are evenly spaced it will make centering and lining up the input shaft on the adapter plate so much easier.

-

Owner first drive zcar/250gt conversion VK56 motor

1969honda replied to 510sr20det's topic in Other V8Z Tech Board

I appreciate that, thank you! -

Owner first drive zcar/250gt conversion VK56 motor

1969honda replied to 510sr20det's topic in Other V8Z Tech Board

Do you have any pictures of how you modified the oil pickup? I've seen a few different takes on modifying the sump and deleting the cast in feed tube from the pickup to the pump; but the few pans I've seen with the lower pan deleted don't have any pictures showing the actual pickup screen and mounting changes. -

Yeah that's the thought process right now. I called clutch Masters because they've done a few vk56 setups for the cd009 with their 8.5" twin disc and a button on the flex plate but they want $2700. I know I can do better than that if I put some thought into it and get a bellhousing. I leave for a month this weekend though so it'll be on the back burner again until and the 4th of July. Hopefully I can get a bell ordered though and have it here when I come home. Hopefully I can get a rotisserie done at that time as well, really been pushing to get excess crap out of the garage so I can get the car in the air

-

I've used Dynamat extreme for a few work projects that held up really well and was easy to work with. For my car though I'm going to use the lizard skin products; it's supposed to work very well and is really light weight. jpndave on here has some lizard skin in a jeep he built that seems to work very well for noise and heat control.

-

Easiest I think will be too adapt the trans to a Titan/Armada bellhousing

-

Awesome updates! Glad to hear it's running and getting close to finished.

-

Great! I've looked around and have a couple lists of how to upgrade the transmission input and main shaft when the time comes.

-

Build notes and rough math for my future reference: 1. Found out the Titan/Armada bellhousing is ~7.250" (184.15mm) from transmission mating surface to engine mating surface. 2. VK56DE crankshaft protrudes into the bellhousing 19.25mm 3. 2000 f-body T56 input shaft measures 135.35mm from bellhousing surface to where the pilot bearing meets up with the splines 4. So taking the bellhousing depth minus the effective transmission input shaft length I get: 184.15mm - 135.35 = 48.8mm Now minus the crankshaft protrusion: 48.8mm - 19.25mm = 29.55mm or 1.163" That means I have 29.55mm of space to incorporate a button clutch of some sort of the vk56 flexplate inorder to retain my factory CAS sensor mounting and trigger wheel. Need to find out more info on the retro t56 input shaft that is supposed to be longer for the older Muncie/T10 transmission swaps.

-

And t-56 scored locally, also picked up a folding engine hoist and another engine stand for under $100!

-

That's a beautiful car, love the twin setup and how you mounted everything.

-

A musician's therapist (The $300 Z)

1969honda replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

Contact Dave about the welder stuff, he has a good friend that's in the know and in sales.