-

Posts

13742 -

Joined

-

Last visited

-

Days Won

68

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by JMortensen

-

Custom rear control arm

JMortensen replied to rvannly's topic in Brakes, Wheels, Suspension and Chassis

I used something like tube80z's idea on a set of arms I built but never used. I just added angle iron so that the end links were in double shear. I would suggest you add your connections to the bottom of the control arm so that you can use longer end links, although this gives you a left arm and a right arm. If you put the mount in plane with the control arm you will still have universal arms but will need shorter end links. -

Carbed 5.3L Dyno 337/334

JMortensen replied to JMortensen's topic in Gen III & IV Chevy V8Z Tech Board

Mine's an L33. Has caused confusion in the past... -

Carbed 5.3L Dyno 337/334

JMortensen replied to JMortensen's topic in Gen III & IV Chevy V8Z Tech Board

No offense taken. When I was 16 I had a bunch of friends who got me into Datsuns and they were all purists, so I came up believing that pushrods sucked and OHC was fantastic, that V8s couldn't rev, that the L series was a fantastic engine, etc. Mid 90s we had Carl Beck's email group and I started seeing people with V8s and who just generally weren't so closed minded. The guy who, up to that point, had taught me everything I knew about Datsuns (and was a Nissan master tech and legit Z car whiz) was one of these "don't go too big on the cam" guys. So I had tiny cams in my truck and my Z. Some people on the internet disagreed, and I remember him saying something to the effect of "how do you know that they know what they're talking about?" I decided to get a much bigger cam than he suggested, and it was a huge improvement, at which point I realized that I could actually have a pretty good idea if someone knew what they were talking about. BTW after driving my L28 with .490/280 cam, he immediately went for a .580/310 or something like that for his L18. At least he realized he was dead wrong. Then I started to notice a lot of people like Pete Paraska were talking up V8s and that put a little seed into my brain. Later I was looking for GOOD suspension tech and John Coffey suggested Hybrid Z, and I took a look and found tons of good information. Same friend had a standard autox alignment: -1.25 degrees front, -1.5 degrees rear, 1/8 toe in front and rear, 3 degrees caster. As it turns out, this is a shitty, understeering autox alignment. Hybrid Z recommended a lot more camber and caster, and more neg camber in front than rear, and zero or toe out in front. Again, huge improvement. And all these smart people on this forum were ditching the L series and running V8s. I came to realize that all of my preconceived notions about adding huge amounts of weight to the front end were just wrong, and I realized that I wanted more power than I was getting from the L28/44 Mikuni combo I had, and it was probably going to cost $10K to get another 50 hp if I kept on with it. Also realized that having intake and exhaust on the same side of the motor is pretty shitty, and since these engines are all smog era designs the combustion chambers aren't great, in short, the L series isn't the best engine design. Had the same revelation about my Toyota truck with 22RE. For the longest time I thought that was a GREAT motor. Now I wish I had pulled my head out of my ass years earlier... Anyway I was looking for more power and by this time I had changed my mind and realized that hp is hp and it doesn't really matter what you use to get it, if the goal is to go fast. In fact, the cheaper the hp the better, since race engines tend to wear fast or break, so I decided on the LS since it's cheap and easy. I still love the sound of the L series and don't hate them, but I feel like I have a better handle on what makes a motor good or bad than I did when I was a kid. -

1970 240Z Race Car Front Suspension Issue

JMortensen replied to Gmagno's topic in Brakes, Wheels, Suspension and Chassis

Just pull the springs and jack the control arms until they're level, and that should be close to ride height. Can check bumpsteer while you're in there. -

1970 240Z Race Car Front Suspension Issue

JMortensen replied to Gmagno's topic in Brakes, Wheels, Suspension and Chassis

I bent mine, front and rear, in all kinds of directions. No problems. -

1970 240Z Race Car Front Suspension Issue

JMortensen replied to Gmagno's topic in Brakes, Wheels, Suspension and Chassis

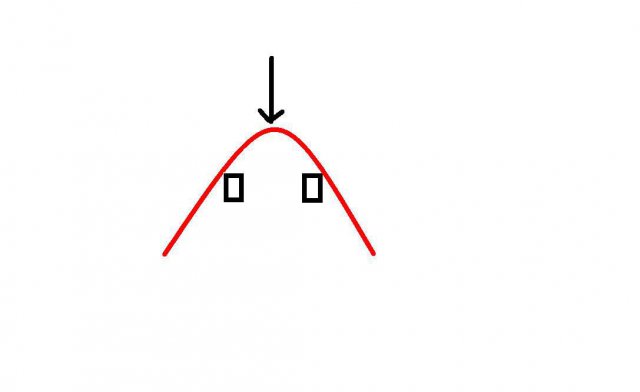

Here's a crappy drawing on bending the bar. Just lay it over the base and push on the bend. Keep measuring eyelet to eyelet. Bend one side until they move 1" apart, then flip and do the same on the other side. 10 minutes max. -

1970 240Z Race Car Front Suspension Issue

JMortensen replied to Gmagno's topic in Brakes, Wheels, Suspension and Chassis

Bend the bar. If you have a press you can bend them pretty easily. Surprisingly easily. -

Here is a partial list of what Larry has done for me and my friends who all grew up 510 and Z people: Rebuilt engines Rebuilt transmissions Diagnosed various electrical problems Installed limited slip carrier in a Z and my Toy truck Built a pie cut exhaust for truck Installed coilovers (cut spring plates and welded new perch on) Cut holes for GC camber plates Helped me make strut tower bars Changed out a timing chain on my Toy truck cam swaps rebuilt and tuned SUs rebuilt and tuned Mikunis and Webers valve adjust (can do an L6 in about 10 minutes flat, does them hot and gets it done before they cool enough to screw up the lash setting) converted a dual point distributor to single point by changing out the breaker plate brake upgrades rear wheel bearings installed Tilton pedal box I'm sure there is a lot more, but that's what I'm coming up with off the top of my head. Needless to say, he can do just about anything. When I moved out of CA about 17 years ago his welding wasn't very good and his fabrication skills weren't super high level either. I imagine he's improved a lot in that time though.

-

JMortensen and Zredbaron at Evergreen Speedway

JMortensen replied to JMortensen's topic in Motorsports / Events

The scoop will eventually be sealed to an airbox on the underside of the hood. It isn't now, but that's the plan. -

Just a little race recap/brag. Super happy with the way yesterday went down. I've had my 5.3 swapped Z out I think 5x, and every time I've had mechanical issues. Not yesterday. Well, I did have some driveshaft bolts loosen up, but I fixed it at the track. Went to Evergreen Speedway's autocross in Monroe, WA. This is a 5/8 mile asphalt oval with a smaller oval in the infield. They run it as kind of a roval with slaloms for autox. There are workers there, no cone shagging, and they limit events to about 90 to maximize runs. I ended up with 12 race runs and another 3 fun runs. Finish line is down the front straight, I was hitting about 90 mph. Mark and I worked on his car all day Saturday fixing a throttle cable issue and bracing his fender so that the tire didn't hit it, then raced all day Sunday. It was a full weekend. We wore Beta Motosports T-shirts in honor of JohnC and of course our cars have hoods and hatches from Beta, mine FG and Mark's CF. Still miss that guy a lot. About midday someone asked what my times were like. I had no idea, so they looked it up (phone app) and I was 5th overall. Then Mark got a rerun and I was able to ride with him and he went into the first turn 10 or 15 mph faster than I was. After using this data point to adjust my driving I ended up placing 2nd overall, and 2nd in class behind a supercharged, stripped S2000. Very happy. Mark was about 1.5 seconds behind, still in top 10. 9th actually. A very successful outing! Anyway, Mark is much better at sharing videos and pics and tagging appropriately than I am, so hopefully he will see this and post some more up, but here is my FB page where we have both posted a bunch: https://www.facebook.com/Jon.E.Mortensen And here is a link to one of my earlier runs. I did better later on, but I kept leaving my phone in my pocket and it was damn near impossible to get out, put the phone in the holder, get it all set up, and get back in the seat while in grid, so I didn't have any vids for the last half of the day. https://youtu.be/XmwkU3N8FB4

-

Clutch still slipping after Install.

JMortensen replied to Phib's topic in S30 Series - 240z, 260z, 280z

FWIW, I would prefer to have a stiffer pp and a normal style clutch than a puck clutch with a lighter pp. Seen flywheels gouged from puck clutches, a friend had the thrust bearing on the crank destroyed by a puck clutch in a CA18DET, etc. I ran an ACT stiff pp with a stock disk and that held down my L28/Mikuni combo just fine. -

Clutch still slipping after Install.

JMortensen replied to Phib's topic in S30 Series - 240z, 260z, 280z

Sure. Relatively slow speed, say 30 or 35 mph. 4th gear with clutch in and floor it. When the engine gets up to ~5000 rpm, dump the clutch. The rpms should immediately fall to 1500 or whatever it would be at that speed. If it comes down slowly, your clutch is slipping. -

Clutch still slipping after Install.

JMortensen replied to Phib's topic in S30 Series - 240z, 260z, 280z

I think he'd know if the timing chain jumped. -

Clutch still slipping after Install.

JMortensen replied to Phib's topic in S30 Series - 240z, 260z, 280z

Not really getting how the clutch slipping is making the accelerator stick, unless it's slipping and you're just flooring it. That wouldn't be the best way to handle a slipping clutch though... Sounds like maybe the clutch can't hold the power down. The test for a clutch is to go about 35 mph or so, rev the engine to 5K rpm, put the trans in 4th and drop the clutch. If the engine doesn't immediately slow down, then the clutch is slipping and can't hold the power you have. When a clutch is marginal you'll also feel it on redline shifts in the higher gears. The rpm will slowly drop to the actual speed of the engine in the next gear. As to the sticking throttle, I had an aftermarket carpet kit that caught the corner of the gas pedal a couple times. After a couple incidents I finally just removed the carpet on the driver's floor to fix. Usually carpets or floor mats. Do you have auxiliary return springs on the triples? Not a good idea to rely on the springs on the carbs. Most (all?) racing orgs will require two additional springs on the linkage. Pretty easy to fab it up too. -

It's been 20 years so my info may be out of date, but my machinist who did my E31 picked Schneider springs because they had much lower seat pressures than the competition, which I think was Erson and ISKY.

-

Master Cylinder Question

JMortensen replied to PatD's topic in Brakes, Wheels, Suspension and Chassis

It's still worth doing the pedal depressor. If you just let the fluid drain out you'll have to get air out of a lot more places. Masters will run dry, etc. Much easier to bleed if you limit the amount of fluid loss. -

Master Cylinder Question

JMortensen replied to PatD's topic in Brakes, Wheels, Suspension and Chassis

You are correct about the soft lines being attached to the strut housings, I wouldn't grind them off, just disconnect and replace if they're old. Pedal depressor works. Done it many times. Can just cut a stick to fit between the seat and pedal with the pedal depressed a bit. Will squirt a tiny bit when you crack the lines initially. -

No (Low) Rear Brake Pressure

JMortensen replied to Twisted46's topic in Brakes, Wheels, Suspension and Chassis

Sounds like you needed a booster anyway. -

Carbed 5.3L Dyno 337/334

JMortensen replied to JMortensen's topic in Gen III & IV Chevy V8Z Tech Board

Interesting to see this one pop back up. I figured out what was going on with the rough running. Wasn't wires or plugs; it was faulty battery disconnect switch and alternator charging. Basically the alternator was charging intermittently and on the dyno day it wasn't working, and the voltage got low enough to cause the ignition to start to fail. Went to an autox after this, ran great. Then went to another and it ran horrible and I saw a tiny wisp of smoke out of the battery disconnect. Swapped out the switch and wired it differently and then it still wasn't charging correctly. Cut the old switch open, the contacts were bent and it was BARELY making a connection. Was looking around for loose connections and turned out the dash idiot light in the charging system was intermittent as well. Moved the bulb around in the housing and suddenly had 14V on the gauge. Point is that the rough running was something entirely unrelated to carb or spark plugs/wires. 2nd lithium battery was killed in the process of figuring all this out. New LED light installed, new switch, new battery coming. Should be back in action very soon. From what I understand it should be making somewhere in the neighborhood of 370ish whp when running right. -

No (Low) Rear Brake Pressure

JMortensen replied to Twisted46's topic in Brakes, Wheels, Suspension and Chassis

Sounds like reaction disk issue. I saw you said you had checked it, but that's what I'm seeing looking at your post. -

Race Car Brake Assistance, no vacuum available

JMortensen replied to 260DET's topic in Brakes, Wheels, Suspension and Chassis

Oh, nevermind. I thought the issue was with the ITBs getting in the way of the booster. Was thinking L6, not V6. My bad. -

Race Car Brake Assistance, no vacuum available

JMortensen replied to 260DET's topic in Brakes, Wheels, Suspension and Chassis

Still need space for the booster though. I think GM's Hydroboost solution would work, not sure, but I keep coming back to wondering why you don't just tweak the manual brakes? Smaller masters will give a lighter pedal, larger will give a stiffer pedal that needs more pressure. It's not that hard to get it right. Here's a youtube video on replacing a broken Hydroboost setup: -

I would suggest you don't go mild on the cam. People tend to undercam L series. I had a .490/280 cam which I ran on a stock compression L28 with SU's and it was great. When I moved up to triple 44s I felt like I needed more cam. Then I went to a higher compression shortblock and I REALLY needed a bigger cam (wouldn't run on pump gas). Never got around to it and went V8 instead, but I was looking for something in the 300 to 310 duration range.

-

Race Car Brake Assistance, no vacuum available

JMortensen replied to 260DET's topic in Brakes, Wheels, Suspension and Chassis

If you just delete the booster and go to the appropriately sized (smaller) manual master you should be able to get decent brake feel. If you drove my car and I didn't tell you the brakes were manual I doubt you'd say anything about the pedal feel at all.