-

Posts

13742 -

Joined

-

Last visited

-

Days Won

68

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by JMortensen

-

Is there different size distributer rotors between the l28e?

JMortensen replied to grillhands's topic in Nissan L6 Forum

The rotor and cap on the 280Z is larger than the rotor on the 280ZX IIRC. -

Different mirrors, but shows how to complete this kind of installation and the issues Pillar mentioned: http://alteredz.com/TercelMirrorMounting.htm

-

New Front Control Arm

JMortensen replied to Mike Mileski's topic in Brakes, Wheels, Suspension and Chassis

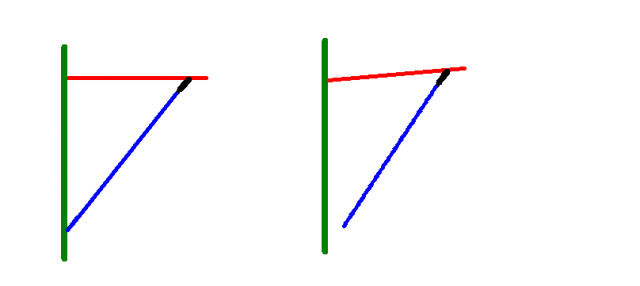

When you add or subtract caster the problem is the LCA angle changes relative to the TC rod. It's not that the TC rod can't move at the heims joint, it's that the fixed stud that you've welded to the LCA won't allow for the LCA angle to change. Made a crappy little picture to show the problem. Took the same image and rotated the LCA 5 degrees forward. You can see that the back of the TC rod is no longer in line with the frame rail. If you had a pivot in the front that could be locked down, then you could swing the TC rod back to the TC box. With a solid connection at the front there will only be one angle that works, no adjustability. -

New Front Control Arm

JMortensen replied to Mike Mileski's topic in Brakes, Wheels, Suspension and Chassis

The more camber a tire likes, the more caster it will like, because caster gives you neg camber on the outside tire when you turn the wheel. This varies from tire to tire. Some tires like a lot less camber, like bias ply slicks, so they will like a lot less caster too. -

New Front Control Arm

JMortensen replied to Mike Mileski's topic in Brakes, Wheels, Suspension and Chassis

Caster adjustments are useful and there are reasons to want more or less at a given time, or with particular tires, etc. Camber adjustments are too, but IMO they're better handled with plates on top, so that every camber change doesn't require a toe change. -

New Front Control Arm

JMortensen replied to Mike Mileski's topic in Brakes, Wheels, Suspension and Chassis

Bad solution. Now you have only one caster setting that isn't putting some kind of side loading on the TC rod and LCA. With the clevis the pieces can articulate and then be locked into their new position after adjustment. -

NA 3.1L=>head & camshaft questions. No shortcuts, max

JMortensen replied to zredbaron's topic in Nissan L6 Forum

There has to be a place closer to you, but if you can't find one Chase Race is right around the corner from me. You could leave your car here if necessary for some reason. Does exhaust, cages, all that stuff. Doug bent the main hoop for my cage based off of Dan McGraths jpg image posted here. Fit perfectly. http://www.chaserace.com/rollbars.php -

NA 3.1L=>head & camshaft questions. No shortcuts, max

JMortensen replied to zredbaron's topic in Nissan L6 Forum

For my part, I'll say that it did seem that Arnie was perturbed by the fact that you wanted to run the 40s and then the 45s. Also surprised me how much time it took to change things between pulls. Between swapping the carbs and putting the freeze plugs back in, there wasn't a whole lot of time for carb tuning. I think there were 2 or 3 jet changes and the one venturi change on the 45s and that was basically it. I think you would have done a lot better if that freeze plug issue hadn't hampered progress. You didn't really explain that, so I will. They were running the engine with no alternator, but needed the coolant to circulate so there was a belt going from crank pulley to water pump pulley. No tensioner. The belt that they were using was just a bit loose, so you could see it flopping around when the pulls were going. I can't remember how many times (3 or 4) a freeze plug would exit the block and make this surprisingly loud "Booooosh!" sound, then Arnie would cut the power to the engine and steam would be everywhere, etc. Every single time it happened I thought there was a hole in the block or some other catastrophic failure. It was a really loud noise that it made. There is a plug under the timing cover too, so we were all worried that if that one popped it would take hours to fix. Mark finally suggested a tighter belt, based on the theory that the belt was catching and slipping and this pulsing of pressure was hammering the plugs out of the block. Belt change solved that problem. That was my first experience dynoing anything. I would like to try to get mine on a chassis dyno. If and when I do, I'll have all of my changes laid out with all of the parts set aside for each change, much like they did for the wind tunnel testing, so that things can be swapped as fast as possible. -

It's one thing to wire up a doorbell (literally saw that once) or a race car push button. What Dave did is a whole lot more than that. He does good work!

-

Del-A-Lum LCA bushings

JMortensen replied to Chickenman's topic in Brakes, Wheels, Suspension and Chassis

The leaning back of the strut is what gives caster. It also changes the motion ratio, but not a lot unless the angles get really extreme. I don't think a lot of people drift Zs, that would be one reason. The other I can come up with off the top of my head is that the TC pocket in back is at an angle. Most of the LCAs with this design that I've seen have the rear pivot pointing straight ahead and then they use an eccentric to push the rear pivot back and forth and adjust caster. That wouldn't work so well with the pocket at an angle. When you move it out to adjust caster positively, you would simultaneously be moving the pivot back, which counteracts the caster gain. -

Del-A-Lum LCA bushings

JMortensen replied to Chickenman's topic in Brakes, Wheels, Suspension and Chassis

Not seeing the problem. Here's a 944 LCA: -

Since the 280ZX has a coilover shock setup in the rear, I think all you need to do is find a shock with an adjustable spring perch that is the right length. I don't recall the motion ratio, want to say it's like 2.5:1, so the valving will have to be about 2.5x stiffer than the front struts. Look on 510 forums. Lots of them convert the rears to coilovers like the ZX has out of the box, and a lot more of those get raced than 280ZXs.

-

Del-A-Lum LCA bushings

JMortensen replied to Chickenman's topic in Brakes, Wheels, Suspension and Chassis

I'd bet that it wouldn't be too hard to do a single piece LCA. Just has to have a rod end at the front and maybe a inner tie rod or something like that at the bucket. So long as the arm is shaped so that the rear pivot can move without binding the joint, should be OK. Would be harder to do with a rod end in back. I'd bet some drifter has already figured it out. They need the wheel clearance for more steer angle so single piece LCA makes a lot of sense for them. -

Del-A-Lum LCA bushings

JMortensen replied to Chickenman's topic in Brakes, Wheels, Suspension and Chassis

Not the best choice for the front. I used them in the rear, but the issue up front is that as the suspension moves up and down it does so on an arc, following the TC rod. The delrin in these bushings is very stiff, so it doesn't allow this to happen very easily. I'd much rather have a rod end in front. The thin, hard delrin bush isn't saving you any NVH. Also adjusting camber with these changes bumpsteer, so if you care about that these make it a lot harder to adjust the bumpsteer out. -

I know John's Penskes were more like $8K, but I do recall a couple years back they were making those kits more available. MCS might be great, but I'm not familiar. If you're just going to lay down cash you might check out Penske as another alternative.

-

Tom, there is a lot of tech on this, just not here. I was looking into it too, and found the nissanroadracing.com forum to be full of S14/S15 solutions to this problem, but we can adapt to our situation too. IIRC John Coffey set up the universal 46mm struts for the rally car that went to Asia. Those are non adjustable, but can be modified to be adjustable. If you want to keep with an insert type of thing, you can modify the 3000GT 36mm Bilsteins to a 280 strut housing and then add the adjustability to it as well. The problem with the bolt on solutions is that all of them are cheap Chinese shocks (most aren't struts, which are designed for side loads). There is the possibility of getting the cheap ones, gutting them, and then putting quality pistons and adjusters on them, but seems like most of the people at NRR.com start with Bilstein and mod those. The other option is to do like Coffey did and order up a custom set of Penske struts and use the adapters that guys are using for the Chinese shocks. Here are a couple examples, there are more over there: http://nissanroadracing.com/showthread.php?t=3344&highlight=bilstein+adjustable+struts http://nissanroadracing.com/showthread.php?t=5266&highlight=3Kgt+strut

-

Driven Daily Hillclimb 2016 Build

JMortensen replied to Jesse OBrien's topic in S30 Series - 240z, 260z, 280z

Man, that's weird. He could have welded the tube directly over the shock mount and made stronger. In fact, some people weld a short piece of tube onto a stock strut or shock mount like that to stiffen it up so that it doesn't flex under load. He was so close, then attached to the corner of the tower instead where the cage bars have less control over movement of the shock mount. I'm sure it's great as is, but was 99.9% of the way there and stopped short of what I would have done. Hard to do that on a Z because it's a strut and lots of us run camber plates, but for a shock it's easy and stronger. -

Twin cam head for the L6 from Derek at Datsunworks

JMortensen replied to Derek's topic in Nissan L6 Forum

I'm not sure if I love that tensioner or hate it. I once had a plastic tensioner on my Toyota truck break down towards the bottom and the piece went into the chain, around the gear and snapped it, stranding me. This happened as I got in the truck to drive home from my wedding reception. Luckily a friend is a friggin ace mechanic and had wife and I on our way home in a couple hours. Bad timing though, in more ways than one. Anyway, I'm just a bit concerned that the chain might snap a little piece of plastic off of the top or bottom. Never seen a chain restrained on both sides like that, although I haven't been into that many timing chains, so maybe it's OK and I just haven't seen it before... -

An anecdote... I went to ONE MSA show in the early 90s. When I was there, I walked down a row of fairly crappy looking Zs, all had triples on them. Most were 40s, a few 44s or 45s. On every windshield was a paper that had the specs on the car, none of them was claiming less than 300hp. That was the last car show I went to. I think DP's cams are good. Are they "super cams?" Probably not. But to say that they're very very good cams is not out of the realm of probability. The guy was a very well respected engine builder. You're not going to get there without the rest of the build, particularly the head work. If the cam price was reasonable, I'd do it.

-

I guess it doesn't show the DP cam in that one. Here's the craiglist ad, says 276whp. I'm not buying it... https://orlando.craigslist.org/pts/5990302876.html

-

https://www.google.com/search?q=don+potter+site%3Aforums.hybridz.org&oq=don+potter+site%3Aforums.hybridz.org&aqs=chrome..69i57.7154j0j4&sourceid=chrome&ie=UTF-8

-

First thing is getting the exhaust to the side of the car. If you make your headers and aren't afraid to cut the fenderwell, that's not a problem. Seem some with a shorty and then a hole through the frame or under the frame on s30, not a fan. I made my own mufflers, very loud. 102 db on the sound meter at WOT. Repacked, added Supertrapp tips, hoping that gets it quieter. If that doesn't do it, will try some auger style mufflers. If that doesn't do it I'm going to try something completely different: will run reversed headers like people do for turbos, then Y it and add a muffler parallel to the engine, then bend it out to the side of the car where there will be a second muffler. If that doesn't do it there will be a Z car with a couple thousand hours in it for sale...

-

I have a 17' tilt, no problems other than the car is almost too wide to fit on it, but that's my own fault. For anyone else looking at these, particularly if you have a really low car, have a look at the "Texas rollback" trailer instead. I don't think they are much more expensive, if at all. On my car with 2" ground clearance to the splitter, I have to put spacers underneath the springs to lift the splitter to about 6" high and then use some 4' long 2x10s as ramps to get the car on.

-

R200 limited slip options for 3.36 gears

JMortensen replied to The Dark Side of Will's topic in Drivetrain

As I recall, there were only 2 cars that came with the 3.36 gears in the US. The 260 2+2 and the 79 280ZX 2+2. A 280Z 2+2 should have 3.54s. There is no carrier break on the R200. The bolts thread into the ring gear, so you can use a LSD with 12mm bolt holes on a ring gear with 10mm bolts. Two methods are to use a bushing, mcmaster.com sells a bronze bushing that is 12mm OD 10mm ID and 13mm wide and it works just fine, or you can just clock the carrier so that the bolts rest on the drive side of the hole. I used bushings in mine, but lots of people didn't bother. The viscous LSD has a totally different output shaft for the diff, so you'd need adapters or something to make it work. I never got into the shortnose swap thing because there was always a whole lot of hassle around getting CV shafts that work. I gather some people have made that setup work, but if you try and search for it the whole subject gets very convoluted and people are trying things and then the shafts fail, etc. Whole lot of BS to wade through to find a workable answer. I would suggest you pull the cover on the diff and check the tooth count on the ring gear, will say 39:11 for 3.54 or 37:11 for 3.36 first. If you have a 3.36 and want to proceed, then I'd look at LSDs that work with the parts you already have. The 87-89 turbo clutch lsd is a good option. You can take the output stubs from your dad's R200 if it has one and plug straight into the 87-89 turbo diff. Or you could get an aftermarket LSD like OBX, KAAZ, Quaife, etc and they will all work as well. If he's going to drag race it you might look at swapping out the stub axles for stronger chromoly units and the halfshafts for CVs. www.modern-motorsports.com sells a few different options for that.