ctc

Members-

Posts

275 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by ctc

-

Factory Service Manual has diagnostics. http://www.xenons130.com/reference.html I have a hard time believing that all those parts are bad. Sounds like the guy is shot gunning things, but hey, I don't know how well you trust him. Search on here, there has been multiple discussion of the problem you have, found three in one minute of searching. I can't remeber off the top of my head, but make sure you don't have a leak in the rubber intake hose after the AFM.

-

Am I correct in understanding you now have a complete 1981 ECU, Wiring Harness, dropping resistors and AFM? Compare your set up to this thread and report back if you have all these components. Complete 81 L28ET swap Guide in FAQ The link is a complete guide in how to install the 81 system.

-

Both the automatic and manual ecu's can be used with either the manual or automatic wire harness. Agree on the distributor and distributor drive. Will need the turbo afm as well.

-

Define easier, megasquirt still requires the distributor be changed. Any ecu will require custom wiring and then there is the tunining. For some of us tuning is not "easy". What is the breakdown on your turbo setup? What distributor, ECU, ect? Factory option is plug and play once you understand what parts you need.

-

The turbo distributor and the NA motors use different drive shafts. You have to match the drive shaft to the distributor. OK, so picture #1 shows an NA distributor, an NA distributor drive (quill) and the oil pump. Reference the FSM for how this positions in the motor. Picture #2 is the NA distributor drive shaft, the end closest to the camera goes into the distributor. Picture # 3 shows the NA drive shaft on the right and a turbo on the left. See the splines on the turbo shaft? That is why when you swap to the turbo distributor you need to change both the distributor drive shaft as well. To swap to the turbo distributor, you need both the distributor and the matching turbo drive shaft. The turbo drive shaft and distributor will fit in any L series engine. You should also download the FSM for both the year of the motor and the year of the car.

-

Your current distributor looks like the one from the 78. You can swp to the 83 distributor, but you need to change the distributor drive shaft as well. Search on the l28ET swaps and they will describe how to do it. You will need to pull the oil pump.

-

Got a photo? I was getting what sounds similar on my Jeep. The front edge of each tread block had noticable more tread than the rear and also the outside edge of each block had more than the inside. If you were looking down at a perfectly square tread block in front of you, the Left upper corner would have the most tread and the right lower corner would have the least. For me it was lateral loading of the tire, I wasn't running a steering stabiliser, the wheel and tire were moving left to right (shimmy) as you drove forward. The same could happen from loose steering or aging suspension bushings. I'd start with simple things like wheel balance, alignment and wheel run out. Then move to suspension and steering. Have you recently refreshed the suspension and steering? Is any of those components loose? Hard to diagnose, without seeing the pattern.

-

It might have warpped when you released the torque on the bolts and two end studs. If the gasket blew, you need to make sure the manifold is flat before you reinstall it. It's just good practice.

-

L28ET exhaust manifolds are know to warp. Make sure it is perfectly flat or you will have exhaust leaks.

-

Piston to valve clearance will depend on camshaft selected. There is an engine calculator out there for the Datsun L engines that let you change gasket thickness and other parameters to calculate compression. Engine cal Search around here for what others have done regarding cams, it will depend on what you want the engine to do and what comprimises you make. For your target RPM band, are you using cast or forged pistons? Also, APR rod bolts I assume?

-

WOW, you are pretty young to be working on z's. But you got the right parts catalog. lol. All kidding aside, you don't have a CAS distributor or coil, so that means you what to cannibalize an 81 and use the crank fired CAS system. Or swap the distributor and distributor drive, but that means dropping the oil pump. My advice, find a complete donor car and get the ecu, harness and ignition coil. Also needed to check the fuel pump to see if it is the turbo pump or not. Search on the many L28ET swaps here and once you find the direction you want to go. Post back and we will help as best we can.

-

Others have done it. It will depend on your experience reading wiring diagrams from the three different cars involved. Can you take a picture of your distributor and coil? That will settle the question about CAS (crank angle sensor). You will most likely be better off getting an 82 or 83 turbo harness and following the guides on this site. Check the FAQ's section for how to do the swap. Also a word of caution, you might want to do basic troubleshooting on why it runs bad before assuming the harness is the problem. Also in you posts please be specific, which stock ecu, which afm, ect. Some people have done some pretty crazy things to cars over the years. Knowing what you are starting with will help others help you.

-

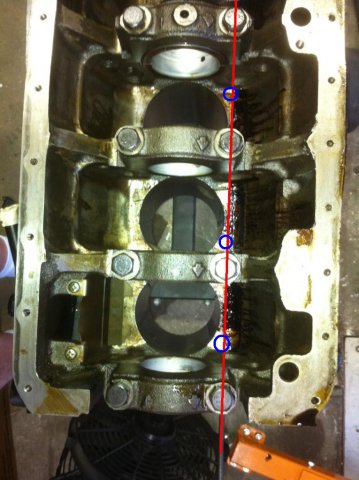

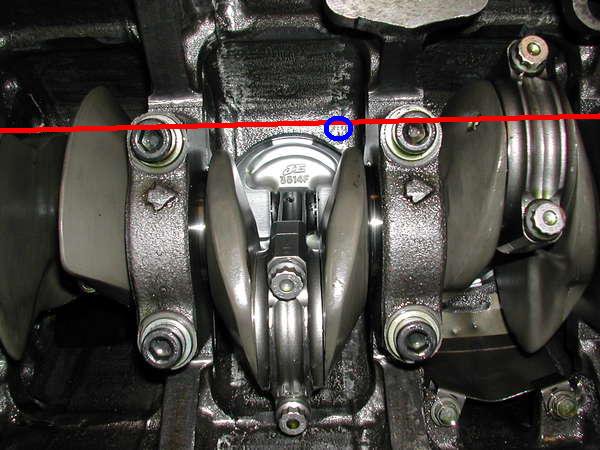

Ok, So I was out the garage taking pictures of the block. Photo one shows the location of the main oil galley that runs the length of the block (red line). The blue circles show the most likely canidate for squirter locations. Photo two shows the front main bearing. Again, red shows the oil galleys and blue shows possible squiter locations. Based on the location of the main bearing feeds, I don't think it would be possible to locate a squirter one the main bearing feed. Also, looking at the bearing, I don't think the squiter in the main bearing cap would work very well. It would take a lot of mods, and the crank would shield the piston for some part of each revolution. Photo three is the one JohnC posted earlier. I wanted to show that with a knife edged crank, the blue circled location would be a very good location for a squirter with very little potential for piston or crank interferance. I think all you would need to do is spot face the block and drill and tap for the squirter. One note of caution that I have found in most of my research on others who have done this, is that piston and crank interferance will be engine specific and must be checked on assembly. I think with the stoker crank, things would get very tight.

-

Tim, how deep do you need to tap the threads for the banjo bolt? Can you please take some photos of the squiter with a ruler to get some approximate dimensions?

-

You might try wolfcreek racing. I thought they had some on their website awhile back.

-

You will want to get the regulator and a good fuel pressure gauge. My Webers like to live best at 3psi. without the regulator I had drivability issues.

-

This is what I was getting at, if you degree the cam you know exactly how much you need to move the timing and would most likely need the Tomei or Kameari adjustable cam gear. As for slipping a tooth, I would assume since there are 40 teeth and 360 degrees that each tooth is 9 deg off on the cam or 4.518 deg crank (see below). Sounds like you should run the shims or an adjustable gear.

-

Pardon my ignorance, but wouldn't you install the cam with zero timing advance? The big advantage of the Kameari part is to take up the extra slack created when shaving the head. With the cam dialed into zero advance and the crank at TDC, the relative location of links on the timing chain are irrelevant because the chain will maintaing the relative position of the cam and the crank. Am I wrong?

-

Measurements of installed pressure plate height are in the FSM (240sx) in your case. For your set-up with a mish-mash of parts, you will need the stock distance as specified in the FSM and your installed height of pressure plate on your fly wheel. The difference will be how longer or shorter the throughout collar will need to be.

-

Depending on the failure, I would be concerned that the cam towers were misaligned. Did the cam rotate freely by hand with it installed in the towers? Where the towers damaged?

-

Sorry to hear that. Do you have pictures?

-

So digging around on the internet, I came up with a link to this BMW install. It's from Sweden, so local for some. http://forum.e46fanatics.com/showthread.php?t=720393 Still haven't tapped into my block yet. I'm thinking I'll either have to bore diagonally back to the main oil galley on the side of the block, or tap the oil flow in each main bearing web and turn it to hit the piston with a custom nozzle. More research is required. More links http://www.e30m3project.com/e30m3performance/installs/installs-3/squirters/index.htm

-

Of course other things can benefit. And again can we talk about technical feasibility here, not cost or how easy it is. To end the coating debate, I point to this link http://www.techlinecoatings.com/articles/Coating_Pistons_Article.htm I will agree that coatings help with detonation and keeping heat in the combustion chamber, and based on the last paragraph, oil cooling of the underside of the piston is possible as well. So, to get this thread back on track, if the goal is to use oil to cool the underside of the piston, where do we tap the block for oil supply? Assume we have a race oil system with enough volume and pressure.

-

John, I agree there can be too much oil. I think this is what the How to Mod Your Datsun book was getting at. And also why they recommended closing off the factory oil squirter. To your point of too much oil, I wonder what the additional weight of oil "stuck" to the bottom of the piston does to balance and engine dynamics? Also, with your comment on race oil systems, do you think, there is enough pressure/volume that tapping a squirter off the main bearing feed would starve the main bearing?

-

I would like to steer the discussion toward combustion temperature, which allows more timing, and not just piston temperature (durability). I agreed that a coated piston is more thermally efficent, but what is the cost of that efficency? I think the increased ignition timing that a lower combustion temperature (detonation margin) will provide will definately be quantifiable. Lower combustion tempertures on a stock engine L-series (EGR recuirculation), allow more timing and power. I am postulating that oil spray will effect combustion temps and timing in the same way.