NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

It's a clue that the problem is not in the ECU. The next thing you might do is to disconnect the power to the injectors. Just unplug all six. Then do the same test with the fuel pump. That will pressurize the rail and injectors but there will be no power to open them If there's still a leak then you'll know it's not electrical. If you try that you might as well disconnect the vacuum hose to the FPR. The FPR diaphragms are known to fail and fuel leaks directly in to the manifold through the vacuum hose. The fuel might not be coming from the injectors. Unplug the injectors, disconnect the FPR vacuum hose, activate the fuel pump, and see if fuel leaks from the FPR. You'll probably know something as soon as you remove the hose. It should be dry. If it is dry and the FPR is good and pressure still leaks down then you might just have stuck injectors. p.s. if you've had gasoline flowing in to the cylinders then your oil is probably diluted with gasoline. You should change it as soon as you solve the problem.

-

When you turn the key on the injectors get power. The power is grounded through the ECU. You either have a short circuit on one/some of the wires on the way to the ECU from the injectors or you have a bad ECU. That is how they fail sometimes by shorting the injector circuit. A simple test would be to unplug the ECU connector and turn the key on. If pressure holds then there's no short. Or disconnect all of the injectors so you don't flood the engine and use noid lights to see if the injector circuits are grounded. The lights will light if there's a short in the wires or the ECU. You can also use a simple test light or make your own test light from tail light bulb.

-

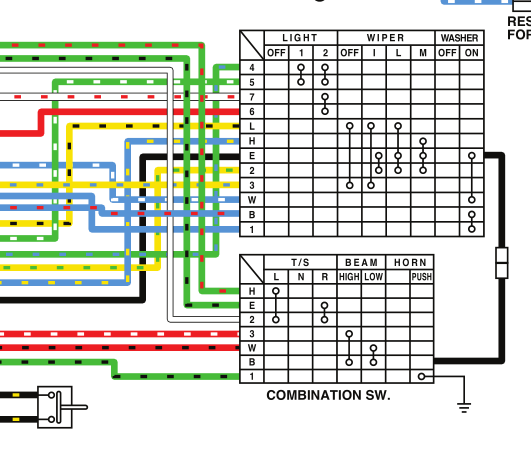

Do you have power to the fuse block now? Follow the diagram. If you have power all the way to the headlights then check the grounds on the other side. The headlights ground through the dimmer switch. The dimmer switch often gets gunked up over time and does not pass current. You can sometimes fix it by spraying contact cleaner in to the base of the turn signal stalk and working the lever.

-

Here's a nice writeup showing the parts and describing the problems. https://www.zcar.com/threads/headlight-combination-switch-repair.311982/

-

The power flows from the fusible links through the combo switch then down to the fuse blocks. It's probably the combo switch. Broken solder joint or pitted contacts. Pretty common. check the solder joint on top of the switch or pop the top off and check the contacts. Be careful there is a spring and a small plastic piece that are part of the mechanism. The running lights go through there too.

-

-

240z ignition switch not aligning

NewZed replied to turbo240's topic in S30 Series - 240z, 260z, 280z

I did not understand what you were describing before. Any chance that you can just twist the shaft housing using brute force? Might be that somebody already did and that's why it is not aligned correctly. Check the mounting bracket for broken welds. I don't know if it is brazed or tacked in to the mounting bracket but an examination should tell you something. -

240z ignition switch not aligning

NewZed replied to turbo240's topic in S30 Series - 240z, 260z, 280z

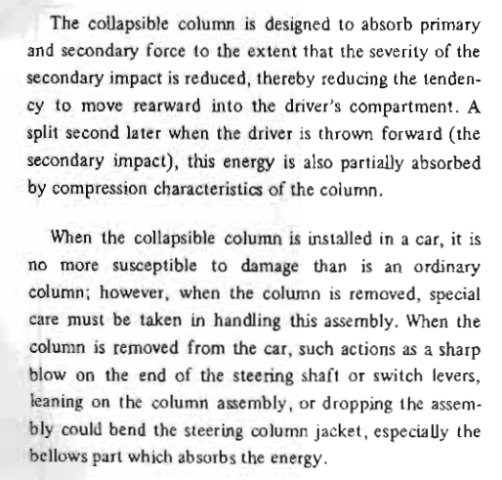

Might be that the column has been partially collapsed. Read up on how it works. This is from the 1973 FSM. I don't know if it stays collapsed or rebounds. -

Tokico Alternatives (Tokico has dissolved)

NewZed replied to Jack B.'s topic in Brakes, Wheels, Suspension and Chassis

Koni is back. Not sure how they handle lowering, MSA probably knows. They might have springs to match. https://www.thezstore.com/page/TZS/PROD/23-1034 https://www.thezstore.com/page/TZS/PROD/23-1033 -

-

Whitehead big brake kit

NewZed replied to jessejames's topic in Brakes, Wheels, Suspension and Chassis

Seems like you're solving the puzzle. Not sure what the big silver torpedo shape is at the hose fitting but it looks like your bleed screw is on the bottom. Better swap the calipers before trying to bleed. Bleed screw on top. Where the air bubble will be. Good luck. Whitehead just seems to be living off of their old reputation. I wonder if the original owners are even involved today. Maybe they'll survive, who knows. -

Whitehead big brake kit

NewZed replied to jessejames's topic in Brakes, Wheels, Suspension and Chassis

What do you mean by this? Here are AZC's own pictures. Looks like some good clues there. Your pictures just show some parts and a tape measure. Not clear what's not fitting. https://arizonazcar.com/brakes -

Are you using the factory EFI system? There's a bunch in this sub-forum - https://forums.hybridz.org/forum/90-l-series/

-

Leaky booster sounds right. The symptoms fit. The IACV setup on your engine was just an attempt to use the computer to control idle. Won't hurt anything to leave it off. You need to start reading about aftermarket engine control. DIYAutotune has some good articles. Also, the Megasquirt pages. https://www.diyautotune.com/support/tech/ https://megasquirt.info/educational/

-

Yes, that looks like quite the assemblage of parts. I think that I see an idle air control valve (IACV), not sure, I pasted it below. That would be where the idle speed is controlled by computer. If it is completely closed and the idle is still high then the throttle blade bypass (idle air bypass) might be too far open. Or you have vacuum leaks. Look at your AEM software for an IACV setting. You could even just disconnect that hose and block the port to see if idle speed drops. If it doesn't check the throttle body for an idle speed screw. I wonder what that rubber hose is going to do under boost?

-

Download an FSM and open the Engine Fuel chapter. You'll need all of the parts shown there if you want to go back to stock EFI. You need a lot more parts than what's in that ad. AFM, injectors, sensors, ECU, etc. Or aftermarket engine management. Make a list of what you have now. It's a complex project. Be careful with those aftermarket parts. Many of them have never been tested on a running engine before they're put on the market. They look neat but might not perform.

-

1976 Alternator Upgrade issue--Please help!

NewZed replied to jersey280's topic in S30 Series - 240z, 260z, 280z

Here's a link. I'd add a resistor. It's the heat that kills them so you probably haven't done any damage. https://www.onallcylinders.com/2018/04/27/ask-away-jeff-smith-keep-killing-alternators/ " On most late model alternators, if the warning light circuit is not employed, running without that resistance in the circuit will cause the alternator to fail. On the plug-in connector, there are four connections labeled P-L-I/F-S. The connector labeled “L” is the only terminal (of these four) you will need to connect to the vehicle. If you choose to not connect a warning light in line (in series) with the wire terminated at switched (12v) power, then you must include a resistor. Our friends at Powermaster recommend an 82 ohm, 5-watt resistor. You can find these at an electronics store or online through a company called Mouser Electronics for less than $1." -

1976 Alternator Upgrade issue--Please help!

NewZed replied to jersey280's topic in S30 Series - 240z, 260z, 280z

I am not 100% sure that you shouldn't have some resistance on that circuit. You might want to search around bit to be sure. Normally the Lamp offers resistance in to the alternator, and blocks the current coming back. It would be a bummer to overheat the circuit in the alternator and possibly damage it. You could put a resistor in line or even a light to be safe. Or, even better, a fuse. Or both. 10 amp would probably be about right. -

1976 Alternator Upgrade issue--Please help!

NewZed replied to jersey280's topic in S30 Series - 240z, 260z, 280z

It doesn't need to turn off after the engine is running. But you might need to install a diode in the circuit. When the alternator is charging the current flows the other way. That's why the Charge light goes out. It can keep the engine running after you turn the key off because it's feeding the system through the wire. Look up the 240Z alternator swaps to see what I mean. Check the wires in the external regulator plug to see if one of them is switched power. I seem to remember that one of them was, besides the L wire. I had a 76 too. Here are a couple of links showing the diode. If you find a switched power wire at the old plug area you could probably just wire it up there. Or try it without a diode and see what happens. You can always drop the clutch while in gear to kill the engine if it stays running. https://woodworkerb.com/home/datsun-240z-rebuild/datsun-240z-alternator-upgrade/ https://www.classiczcars.com/forums/topic/46888-240z-alternator-upgrade-instructions-w-pictures/ -

1976 Alternator Upgrade issue--Please help!

NewZed replied to jersey280's topic in S30 Series - 240z, 260z, 280z

Yes. You'll need to supply switched power to that terminal on the alternator. -

There's also the Jeep CAS. One link below, of several. Why are you using the head with the smaller valves? There are several versions of the E88, I think, with different combustion chamber sizes. Make sure you're getting what you want. The E88's popularity comes mostly from when it was an upgrade for L24's. The L28 N42/N47/P79/P90's have the biggest valves of all of them. Valve size = flow. Good luck with the project. http://www.zhome.com/ZCMnL/tech/head.htm

-

Not really clear what you're suggesting. "Pigtail" really just means "twisty wires that aren't connected to anything". The ZX distributor module has a power wire and a coil negative wire. You can get rid of the ballast resistor. The two wires that might need to be connected (spliced) would be the Start power and the Run power from the ballast resistor. On the ZX module the pins are marked B and C. B is battery power and C is coil negative. So, you can connect Run and Start at the coil positive and run a jumper to B on the module, and then just connect C to coil negative. That will supply the coil and the module with power and the ground for the coil through the C pin. Make sure that the distributor body has a good connection to ground. That is how the module gets its ground. Through the distributor body. Most distributors have a separate black wire that grounds the distributor body, even though the mounting bolts should be enough. And, did you get the pedestal with the distributor? If not, ignition timing will be off. Here's a link with a lot of extra information. It's a good reference but goes way deeper than you need to go. Although you will want to disconnect the old module by the fuse box. Good luck. http://www.atlanticz.ca/zclub/techtips/distributor/index.html

-

I think I see the reason that Whitehead might take extra long on yours. If they can't keep up with normal diff builds then your special requests are going to add even more time. Good luck.

-

I'm not getting a clear message out from what you're writing. You said you can't find the pinion bearings but Rockauto has a big selection. You could buy one set of each and still save over Whitehead. Now you say you want Japanese parts. Maybe you're being too picky. Sakura Garage could probably get it done or help you find parts. Or ArizonaZcar. You'd need to know what you want though. Whitehead is just a bad choice. You should cancel your order and start over. https://www.sakuragarage.com/home https://arizonazcar.com/

-

If you gave a little more info on your location somebody might know of a shop that could do the whole thing for you, in the states.