NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

They tend to get gummed up. Careful application of carb cleaner will fix them. Resistance across the pins to the internal heater is about 60 ohms it you want to check for electrical breakage.

-

You should be able to throttle any engine down until it dies using the "throttle". Throttle, strangle, suffocate, keep the air out and the engine can't run. If you can't you have an intake leak somewhere, as noted above, or the throttle body needs adjusting. Even the idle bypass on an L6 throttle body will let the engine rev high if it's cranked open.

-

No spark from coil to distributor

NewZed replied to Qcsfinest280z's topic in S30 Series - 240z, 260z, 280z

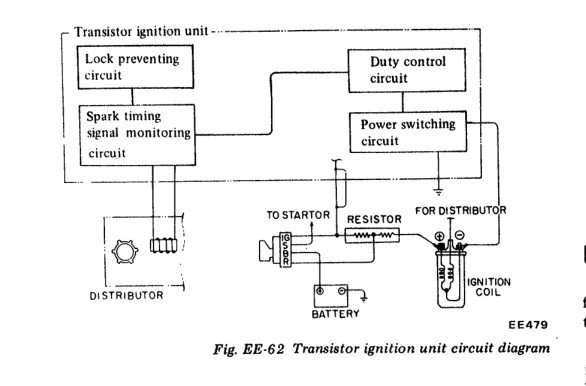

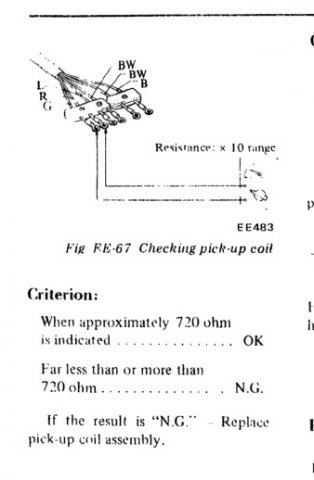

You should be measuring resistance at red and green. Page EE-31. The weird thing about transistors is that they can show voltage, but won't have significant current flow. I don't know if 12 volts at red is normal or not. But the resistance through the pickup coil circuit is important. The flow path would be red wire from pickup in distributor to terminal on fender well through ignition module in cabin then back to terminal on fender well and back to distributor's green wire (some reman's use two blue wires from the distributor, green and red on the inside though). That's the trigger for the module. Then The blue wire connected to the coil negative and the module makes and breaks the circuit based on the signal in those two wires. Easy to get lost in there. That's why the diagram is handy. There are other simple tests you can run while you're in there. -

S13 Rear Subframe upgrade for 260z

NewZed replied to grayson260z's topic in Brakes, Wheels, Suspension and Chassis

Would you start this project from scratch knowing what you know now? -

No spark from coil to distributor

NewZed replied to Qcsfinest280z's topic in S30 Series - 240z, 260z, 280z

Progress. Don't forget to check the blue wire. It needs to be connected to the coil negative at one end and the ignition module at the other. The wiring diagram in the Engine Electrical chapter would help. Other wires that need to be connected to the module are the red and green wires from the distributor. That's where they go after the terminal on the fender well. -

Of course, you've checked for power at the pump and know that it only has power when the engine is running or the key is at Start. Then jumped power to the pump just to be sure you're not wasting your time. If so, time for a new pump. Several options out there, many opinions.

-

There probably is but it's just not injecting from the injectors. Loosen a hose clamp on the fuel system after cranking for a little while and see if anything squirts out. Have a rag handy and no open flames or lit cigarettes.

-

WTB outer bushing shaft for rear lower control arms

NewZed replied to terolla's topic in Parts Wanted

The only outer shaft in that area that has a bushing is called the spindle pin. Here's an option, or you can buy a new one. http://forums.hybridz.org/topic/116959-58th-bolt-option-for-spindle-pin-replacement/ -

No spark from coil to distributor

NewZed replied to Qcsfinest280z's topic in S30 Series - 240z, 260z, 280z

That thread problem was an injection issue. No fuel. You can check your coil operation by attaching a wire to the negative post of the coil, one end only, then turning on the power and tapping the other end of the wire to ground. Set the main wire from the center of the coil close to a ground area, like the valve cover or intake manifold, that's where the spark will happen. Each tap will make and break the circuit to the coil and should create a spark. But, it looks like your mechanic is going to do the testing and he doesn't seem to have a very good method. He's swapping parts without knowing why. Does the tachometer move when you spin the engine? It may be that your guy just left the blue wire off of the ballast resistor. The blue wire controls the ECU, the tach and the ignition module. It's circuit runs to the negative post of the coil. Edit - actually the tachometer may not move if the ignition module is bad. No spark, no pulse. But, a minute with a multimeter under the dash at the ignition module or at Pin 1 at the ECU connector will tell if it's connected correctly. No blue wire, no run. Easy to overlook after an engine swap, especially if the ballast resistor was messed with. -

No spark from coil to distributor

NewZed replied to Qcsfinest280z's topic in S30 Series - 240z, 260z, 280z

Toned down and rephrased - coil has power...no spark...help, is not enough information. And you're in the wrong sub-forum. Something for you to check - what causes the ignition module to break the coil circuit? -

5/8th bolt option for spindle pin replacement

NewZed replied to hwvigo's topic in Brakes, Wheels, Suspension and Chassis

Is this just to save $10, or convenience? If you cut the notch for the lock bolt, and get the distances right between the nut and the bolt head, you essentially just end up with a spindle pin of slightly smaller diameter. You can get a new Nissan pin for $22.23. $12 to get you going in a pinch is one thing, but there's no improvement here. It's not an "upgrade" it's just different. It's not even really a swap, since it's essentially a "downgrade". Just saying, I understand the urge to tinker but there doesn't seem to be any good reason to do this unless you're in a hurry, short $10, or have modified your suspension to where the stock pin doesn't fit anymore. -

An addendum to superlen's advice - test at the ECU connector. See through the wires of the ECU. While you're there, do all of the other tests in the Engine Fuel chapter..

-

Chris Forsberg's Daily is an RB swapped 280z

NewZed replied to palauoriginal's topic in Non Tech Board

Never mind. I drifted in to a rant. I guess it's like snow-boarding and skiing. -

(75 280z) little bit of smoke coming out of the injector.

NewZed replied to Zmanj87's topic in S30 Series - 240z, 260z, 280z

Probably fumes from raw gas on exh. Mani. The intake only sucks, no puffing.p Check hoses before fire. -

@&*()%$ intermittent power failure '78 280

NewZed replied to dicky's topic in S30 Series - 240z, 260z, 280z

Watch tach, measure fuel pressure. Ignition module or fuel problem. -

First Z slow progress build thread

NewZed replied to grayson260z's topic in S30 Series - 240z, 260z, 280z

Only if you're in the herd - "You must log in first". -

Check the head-cooling thread and you'll find pictures of some heads that have been sliced open. My impression is that there are not really passages designed for flow but just big open areas between the tops of the cylinders and the valve train support and valve guides and the outer walls of the heads. It's part of the cooling problem, the coolant's easiest flow path back to the thermostat area leaves areas of low flow. http://forums.hybridz.org/topic/59029-head-cooling-on-cylinder-5-solutions/

-

Which direction to go for fuel/timing/ECU/etc

NewZed replied to Mycarispurty's topic in S30 Series - 240z, 260z, 280z

Are you sure that the Z31 EMS on an L6 can be "flashed" based on a list of components? Chips or reprograms are typically based on high volume stock setups. That's where the customers are. Call the place(s) you expect to do the work and see if they have a clue about what you're using first. -

There are calculators out there. Here's one - http://www.rceng.com/technical.aspx?UserID=22496983&SessionID=uyj162uihRKj2TG6a7lX

-

Check the Maintenance chapter of the Owner's Manual for the various plastic containers- http://www.xenons30.com/reference.html And WD-40 is not a very good lubricant. Use motor oil, since it's a motor

-

Fatigue or just BAD FABRICATION WORK?

NewZed replied to New-to-240z's topic in Fabrication / Welding

Actually, that makes sense since weld quality would usually be covered by the diff cover in the drift world. Maybe they decided to branch out and got exposed. Good luck with the lawsuit. Couldn't resist the weld comment. I don't really get drift-world. I did it in the rain when I was in high school but got over it. -

Actually, the main difference from 76 to 77 was that 77 and later stopped using the AFM fuel pump switch. I've had 75-78 AFMs on my 76 EFI system and they all work fine. Nissan even left the contacts in my 78 AFM, they just weren't used. So, in your case, you'd end up with vestigial fuel pump contacts. It's the ECU's where things can get odd. OAATS, I see that you flipped the years 76 and 77. He's asking about 76 on a 77, not vice-versa. A 77 on a 76 might not work if the pump contacts were gone.

-

Probably key that they distribute the load. Don't use the typical skinny forks. They might be used to framed cars.

-

Interested in how the DP LLC parts fit and work. Looks like they centered the inner mounting points of the link, where the stock configuration has offset bushings. Seems like they gave the option of using the stock TC rod also. They look very adjustable though.

-

Maybe you should sell it with paper work for nostalgia and collectability and get a better car for function and purpose.

- 10 replies