NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

I made the original post just because it was funny to watch the guy drive around a flat parking lot at 5 mph. But, really, it would be noteworthy if someone developed an on-the fly adjustable suspension system for the Z's that was actually usable. It seems like one big problem with sticking an air balloon on top of a spring is matching rates. The balloon might lift the car but if it's a low spring rate then it's like having a two stage spring. You'd probably have to design a specific air bag to match the spring it's perched on to match the response of a single spring. Maybe, with the fine thread pitch on the typical adjustable spring perches, someone could rig up a servo motor that would spin the adjustment to raise and lower a car. You could even get more sophisticated and flip the strut like the Bilstein setups and put the mechanism inside the cabin on top of the strut tower, to keep it protected and to keep unsprung weight down. Of course, it costs money and time to develop new products, but the interest level in "slamming" seems to make it worth thinking about, for a business person.

-

Doesn't this post imply that there might be too much taper in the bores? It turns free with no rings, but tightens up when rings are installed. Probably checking ring gap at the top of the bore. Gap closes when the pistons drop down the bore, due to taper. No pro, just read a lot.

-

If it is bagged, the guy should show them working. That would be something, a slammed Z that's actually usable. Here's a "real" Z, with some drifty doughnuts in the video. It's the other end of the utility spectrum. http://www.youtube.com/watch?v=Mpkr2co95VI Edit - found the video of the first car moving up and down on air. No actual rolling though. Weird. http://www.youtube.com/watch?v=96em7WySA80

-

It's the rear differential ratio that matters, not the transmission ratios. Your 240Z could be 3.36 (manual) or 3.54 (auto). The 75 280Z diff is most likely a 3.54 if it's an R200. And it probably has a funky pinion flange bolt pattern. Better read up on that, it can get you. Flange patterns are described in the JTR book.

-

Came across this video of a super-slammed 240Z. He's driving as fast as he possibly can in the only place he can drive it. At about 2 minutes you can see the bump that keeps him trapped. http://www.youtube.com/watch?v=zyhkFpLbof4

-

Torsional Rigidity Testing, 280Z

NewZed replied to Chris Duncan's topic in Brakes, Wheels, Suspension and Chassis

Somebody linked to the video below from another forum. Seems related to the topic here, he's fixing a tweaked chassis. Shows how malleable the bodies are. As noted earlier, don't over-stress (strain) the body to get test results. http://www.youtube.com/watch?v=3vOk3WPb_3k -

morbias could be right. I misread Post #1 and thought you had a ZX alternator already. I think, though, that both Z and ZX Nissan factory-issue alternators use a D-shaped shaft and hole to mount the pulley and the later alternators use round. Aftermarket "rebuilt" alternators tend to use full-round shafts. Regardless, you have a broken alternator with a pulley in your car. Take it off and see if it will swap. I converted a Maxima alternator and had to shim the pulley out and do some grinding on the case. I used the pulley from a rebuilt parts store Bosch alternator. Pretty easy, but takes more than just swapping the pulleys. If you have some time and tools, it can be figured out.

-

Looking around at valve grinding sites I came across the link below. Generally, if you have to misspell something to get attention it's probably got some BS attached. But who knows... Halfway down with a picture - grooves in the intake valve to disperse fuel droplets. http://www.allpar.com/fix/holler/valve-prepping.html

-

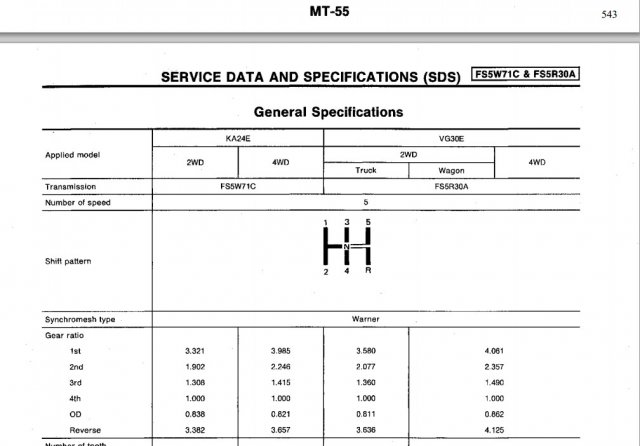

Opportunity to keep the picture-editing skills in shape. 1995 Pathfinder ratios. Edit - of course the 4WD's transfer case would be an issue. Better check overall transmission length also, Nissan likes to make the truck transmissions shorter.

-

The most common cause seems to be high resistance on the coolant temperature sensor circuit. TPS stuck on WOT and CSV leaking seem to crop up occasionally.

-

Fatigue or just BAD FABRICATION WORK?

NewZed replied to New-to-240z's topic in Fabrication / Welding

When you say "track" do you mean open pavement to "drift" on? And have you hit any curbs since the work was done, or let someone else drive your car that might have? Did you bottom out the shocks, or do they bottom constantly like a bad Honda? The work definitely looks bad, both in design and execution but the failure mode looks like there's more to the story. That gap at the failure point is big. Does the gap close when the front end is lifted or stay open? And have you checked the inner control arm mounting points to see if there's not something else broken? Was the lip of the fender bent when they did the work or did it get bent when the failure happened? Hard to believe nobody told you that worked looked terrible. Fair for a home garage first-timer, but not from a professional shop. Thanks for sharing though, it's a good story. Post more pictures. -

Stock what? You're in the L6 forum and haven't even ID'ed your car. If it's a 280ZX turbo system your tach might already be using a square wave. Maybe you can tap in to that line. Your ignitor uses a square wave also, I believe.

-

You probably make a GM HEI module do the job. Details on your engine management system would help.

-

No problem. z240 is right on the 92 mm number. Several people have concluded that independently. Seems to work. Edit - It's funny how many odd numbers Nissan has in the FSM's. Won't help you but they show that the 225 mm 1972 pressure plate is 44 mm from friction surface to diaphragm surface, 1976 is 33-35 mm. They don't give the throwout collar distance though. Just a curiosity.

-

The pressure plate height is the key. Apparently the earlier 240Z's had a tall 225 mm plate, the pressure plate got shorter for later 225 mm clutches, and the 240 mm has a taller pressure plate. Easy to get a mis-match of parts. This link illustrates. You can see the early Type A 4 speed has a short collar. The later more common Type B uses a tall one. And there are variations in between, and after. Not really clear what Nissan was doing. http://zparts.com/zptech/articles/trans_swap%20parts/4tobear_specs1.html

-

Forgot your picture...

-

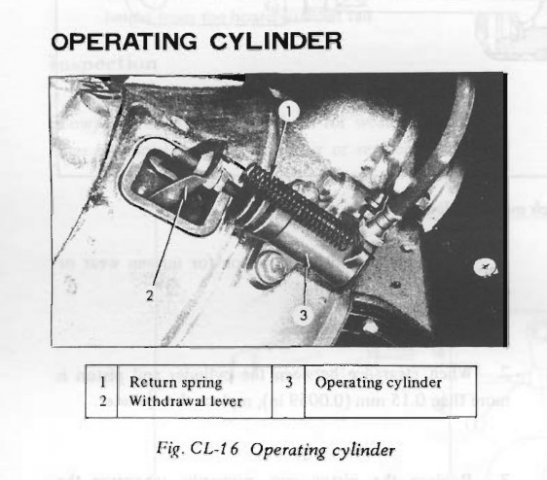

Hope it's not the case, but it could also be the wrong, short, throwout collar. You can get an idea by looking at where the fork sits in its hole, and its angle, when it's pressed against the collar. If it's angled back and sitting at the back of the hole, that's a problem. Could also be an issue with the fork pivot pin, though that would be uncommon.

-

Help with wiper motor wiring needed

NewZed replied to docjim's topic in S30 Series - 240z, 260z, 280z

Which manual are you using? The 1972 diagram seems pretty simple and straightforward. There's not even a relay to figure out, just three wires from the switch to the motor, a ground, and a power wire to the fuse box. If you have the switch and the motor, all you need is wire. Even the later models with six wires have everything shown and labeled, 1976 for example. You just have to work through more connectors, the ignition relay and the intermittent amplifier. Talking about the Factory Manuals, not Chilton's or Haynes. -

360 HP is 90-95 300ZX. You'd be looking at the 81-83 ECU replacement. They all look like scams though - "The results are proof positive" - then they don't show any results. Surprised to see MSA selling those. Seems like they're going down the "new customer born every minute" route. They'll be selling gas mileage improvers by vortex technology soon.

- 21 replies

-

Maybe the problem is in the transmission. You never said if you tried to turn it by hand, but since the engine is out it should be easy enough to remove the transmission and give the engine a spin by hand. If the transmission is still attached do a before and after test.

-

Take the valve cover off and see if the eccentric is intact. Crank the engine and see if the pump lever moves.

-

CR would be about 7.7. You probably won't be able to take advantage of the bigger valves, even if they don't hit the cylinders due to the smaller L24 bore. No more power, more problems. You could probably trade that P90 head for a complete running L24 engine.

-

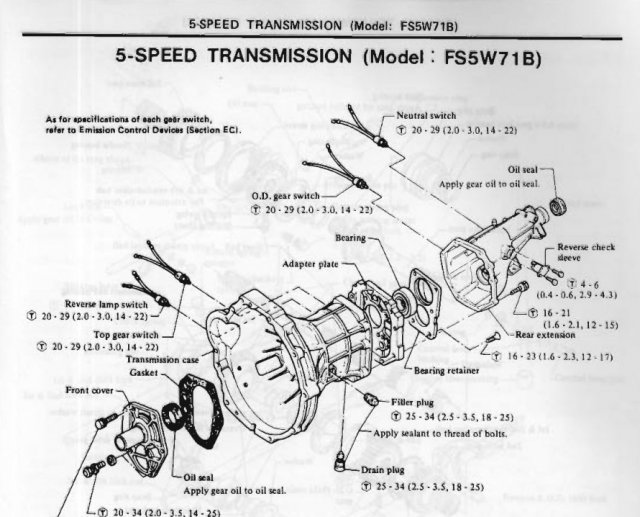

I have an 83 5 speed in the garage. It has four switches. Attached a picture. My 1976 had two switches - top gear and reverse.

-

1979 is more like a Z then. The 81-83's have a bunch. Popping fuses to find the bad circuit might tell you something. Good luck.