NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

FPR could have a bad diaphragm. On an NA car a bad (cracked or holed) diaphragm leads to extra fuel getting sucked in to the manifold through the FPR diaphragm. Under boost, the opposite would happen, you'd push air in to the fuel lines through the FPR. Rich NA, lean boost. Let it idle, no boost, and check the FPR vacuum hose for fuel. I'm just guessing, not a turbo guy.

-

-

Search the words "square port round". You'll find some good reading. Round can go into square but square won't go in to round. Round blocks the corners. As far as block compatibility with the head, it's more about piston compatibility with the head. Compression ratios.

-

To JMortensen's point. You should read the thread below. Q45 axles, not 280ZXT, but might be a similar problem. http://forums.hybridz.org/topic/110723-q45-vlsd-tearing-up-cages/?hl=shafts&do=findComment&comment=1035217

-

Maxima alternator swap questions(search isn't helping)

NewZed replied to Milenko2121's topic in Ignition and Electrical

I modified a 90 amp Maxima alternator for v-belt use by swapping the pulley. The pulley from your ZX alternator might need to have the hole enlarged if it's a factory unit. It might be D-shaped. You'll need to make a spacer (or stack some washers) behind the pulley to get the alignment with the other pulleys correct. The Maxima microgroove pulley has a standoff built-in. And you might have to grind or file down some of the alternator housing behind the pulley so it doesn't rub. Mine looks like it will work, compared to stock, but I haven't had it on yet. It's bigger than the original so it will be harder to squeeze in to its spot. And you'll probably need an impact wrench to get the pulley nut off, for both alternators. There's nothing to grab and it will probably have had thread locker applied. If you try to hold the pulley you'll probably damage it and it might slip on the shaft anyway. Simple in concept but a lot of small problems to solve. -

Read Post #45 also. If your axle is too long, it might be because it's a rebuild with new center, or aftermarket new, not Nissan stock. Also, flipping the cages was the common recommendation (now fairly well discounted) for the 300ZX four bolt turbo axles. Might not apply to the 280ZXT CV axles.

-

Aren't some the 88 LSD's of the viscous type? VLSD. With special axles needed? Something to check.

-

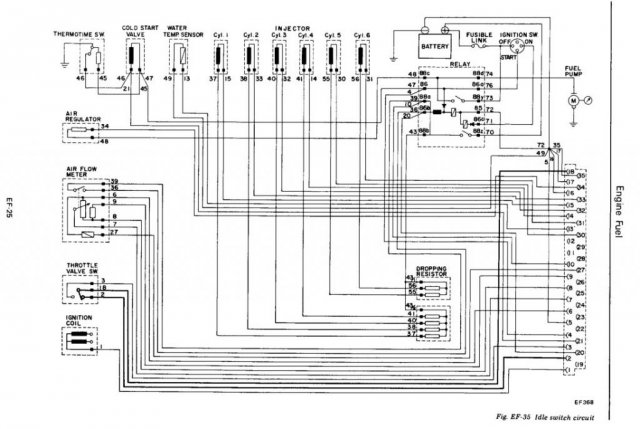

You can uncrimp the sides of the metal cover and take it off. Look inside and see why it's getting stuck. It has eleven blades so it's not so simple to replace with one or two common relays. Added a drawing to show the complexity. From the 1976 FSM. Doesn't look like fun, although it could be figured out. .

-

I thought this thread was about a person you knew with indigestion and a bad attitude... If it was NA I'd say you had a lean condition, maybe a lean spot in the AFM or low fuel pressure. But the same should apply to boost I would guess. What's your fuel pressure? edit - pretty sure that the FPR raises fuel pressure under boost, just like it lowers it under intake vacuum. If the hose from the manifold to the FPR is off or blocked, you'll be rich off-boost and lean on-boost. Somethng to check.

-

Check your shift forks for cracks or excessive wear. They're expensive. If the shafts were out of alignment due to missing bearings, other problems can occur. That's probably what caused the cracked gear. The other gears must have had serious stress put on them too. You'll probably find enough other parts that need replacing that you'll wish you hadn't tried to rebuild, if you go that way. I'm no expert but it seems like a tranmsission with just worn bearings and synchros would be a better starting point for a rebuild. steved033 wins the guessing contest. Maybe he tried to rebuild his two and has some knowledge to pass on.

-

http://www.liveleak.com/view?i=3c7_1370751956

-

10 years after hybernation - '75 280z

NewZed replied to tamo3's topic in S30 Series - 240z, 260z, 280z

Looks like you're deep in to things. I noticed your measurements on the throwout collars and you might be measuring to the wrong spots. The critical dimension is from where the clutch fork contacts the collar to to where the bearing contacts the pressure plate levers. I modified one of your pictures to show it.- 230 replies

-

- 280z

- hybernation

-

(and 1 more)

Tagged with:

-

The Engine Electrical chapter of the FSM has a section on how the ignition system works. 1978 doesn't have a crank position sensor.

-

Need the genius LS guy opinions

NewZed replied to mattd428's topic in Gen III & IV Chevy V8Z Tech Board

Wrong sub-forum. -

Z31 N/A ECU, Harness, MAF, Dizzy, into 73 l28et question

NewZed replied to Daphur280's topic in Turbo / Supercharger

Sometimes a click and eyeball search is better. Several good threads here - http://forums.hybridz.org/forum/92-turbosupercharger/ -

"for idle". The FPR has a hose connected to the intake manifold to drop fuel pressure based on intake vacuum. Typical idle pressure is 26-30 psi.

-

Are there signs in the CV shaft assembly that it is too short? Signs of wear? Maybe they're just wearing out. It doesn't seem like many people use the 280ZX CV shaft adapters. Haven't seen many accounts of their use. Here's a thread describing another adpater that several people have used. Up to an inch thick. It seems like there should be plenty of extra room for a stock 280ZX CV shaft. Go to Post #35 - http://forums.hybridz.org/topic/34048-more-questions-on-cv-axle-conversion/?hl=adapter cygnusx1 used to have another thread with prints of the adapters but it has disappeared.

-

You're starting a shop just to focus on pre-83 L6 Datsuns? What is your area of expertise - composite molding, tooling, engine building...? Just curious. Examples of previous or current work would be interesting.

-

Don't know why your idle would drop from1200 to 500, with a click. But, people get the AC compressor power wire and the BCDD power wire mixed up quite often. They look similar. Try turning your AC on and see if the BCDD clicks. And 37 psi is too high for idle. Sounds like you don't have manifold vacuum to the FPR.

-

In your case, the 81 troubleshooting chart is only good for ideas about how things work and some cause and effect clues. 81 had a separate Turbo Supplement that describes the three plug ECCS. The main 1981 FSM is for the 35 pin style ECU. The concepts are the same though. Sensors provide information that the ECU or ECCS computers use to determine fuel enrichment. Pretty sure that after the whole ECCS analyzer section in the EF&EC chapter there is some basic multimeter testing that you can do. You just have to work through the whole chapter. Take notes on where the good stuff is.

-

I opened up the 81 FSM, but it looks like Nissan changed things in 1982, to focus on the ECCS analyzer. Probably worthwhile to look at the 81 just to get some ideas. Nissan tried to make things easier but just made them more complicated instead.

-

Good luck. There's a third of a page dedicated to "Poor gas mileage". EF&EC 18.

-

You're probably seeing something else. Sounds like you just have a plain old externally regulated alternator, on an old 1975 280Z, with a bunch of old corroded connections drawing enough current at idle to put your headlights on battery power. Revving the engine provides enough current to charge the battery and run the headlights. A PO decided to replace one of the fusible links with a fuse in the past. Not uncommon. I plugged your part number in to Google and it comes up as an externally regulated alternator. You can move on to cleaning electrcial connections and fixing other worn-out stuff.

-

The engine wouldn't even run in the last post in your link, now you're driving it. Open the ZX FSM that fits the year of your engine and go through the troubleshooting in the EF&EC chapter. Check the CHTS circuit first.

-

I'm going to guess that your dad has big feet. Check where they've been.