NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Diagnosing flywheel/transmission vibration

NewZed replied to bawfuls's topic in S30 Series - 240z, 260z, 280z

Sounds like something heavy then. Flywheel or pressure plate. The transmission shafts don't have much inertia, near the center of the circle. With the clutch in the pressure plate is disengaged from the clutch disc, which itself has negligible mass, and transmission shaft. See if one of your friends has a flywheel, clutch disc, and plate setup in their garage. Maybe they'll let you borrow it just for a test. I have two myself but I'm in Oregon. Most of us don't have our parts balanced, they come just fine from the factory or the store. It's weird that your guys had to do so much. -

Diagnosing flywheel/transmission vibration

NewZed replied to bawfuls's topic in S30 Series - 240z, 260z, 280z

Always a possibility that the shop that ground your flywheel and balanced your parts didn't get it quite right. Maybe the smoothness of the electric motor is exposing what are actually small imbalances. Good luck. -

Diagnosing flywheel/transmission vibration

NewZed replied to bawfuls's topic in S30 Series - 240z, 260z, 280z

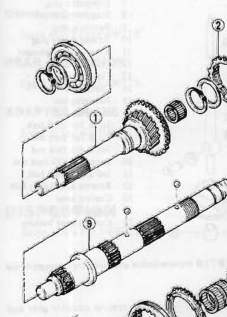

Just to add an illustration. The main drive gear, as they call it, is pretty short. The needle bearing is between the main shaft (9) and the drive gear (1). -

Diagnosing flywheel/transmission vibration

NewZed replied to bawfuls's topic in S30 Series - 240z, 260z, 280z

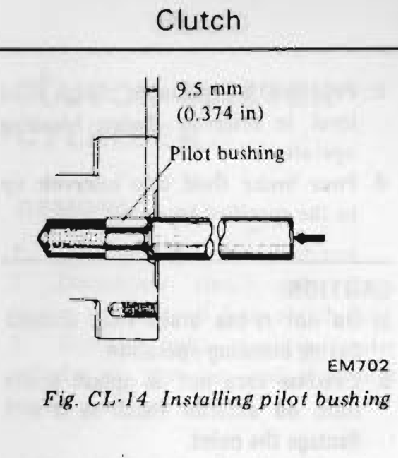

If you engaged the clutch with the input shaft pushed off-center it will be orbiting around the true center. Probably pushed to one side. Is your pilot bushing set right? Seems like the input shaft was pressing on it. -

Diagnosing flywheel/transmission vibration

NewZed replied to bawfuls's topic in S30 Series - 240z, 260z, 280z

I can. You had the input shaft bound up between its bearing and the end of the motor shaft. It's going to be cocked slightly, no way to rotate on-center. All transmission input shafts have some play in them. I had four in my garage at one time, they all have play. The bearing in the transmission is a ball bearing, balls in races. There's play, it's not a needle or a tapered roller bearing bearing. That's why the pilot bushing is so important. I think that you might have found your problem, the bind between transmission bearing and motor shaft. I wouldn't spend any extra money until you put it back together with things they way they're supposed to be. -

Diagnosing flywheel/transmission vibration

NewZed replied to bawfuls's topic in S30 Series - 240z, 260z, 280z

Don't overlook either, the old backward clutch disc. Springs toward the bolts can cause rubbing on the bolt heads. -

Diagnosing flywheel/transmission vibration

NewZed replied to bawfuls's topic in S30 Series - 240z, 260z, 280z

Okay, I watched the videos. They're actually very short and kind of cool. I wonder if your clutch disc is bent. Not uncommon, if you let the transmission hang on it by accident. That might cause some drag even with the pedal depressed and vibration. You could put it back together without the disc and give it a test. -

Diagnosing flywheel/transmission vibration

NewZed replied to bawfuls's topic in S30 Series - 240z, 260z, 280z

With the clutch disengaging the transmission the pressure plate and flywheel spin around the clutch disc and transmission main shaft. If the transmission is in gear and the clutch pedal depressed it should be like the transmission is not even attached to the engine. When you engage the transmission the imbalance is probably magnified by the extra mass of the transmission input shaft. You must have done some machine work to make the end of the motor's drive shaft look like the end of a Datsun engine's crankshaft, for the pilot bushing and the to mount the flywheel. Seems like you might have something off there. The "coupler". Good luck. -

Diagnosing flywheel/transmission vibration

NewZed replied to bawfuls's topic in S30 Series - 240z, 260z, 280z

I didn't watch any of the videos. Too much time, I like words. Did it vibrate when you held the clutch pedal down? Disengaging the transmission from the engine and flywheel? Did you install a pilot bushing in the main/drive/"crank" shaft? If the nose of the transmission shaft is not supported and centered it will orbit around a center point. Off-axis. When you disengage the transmission, using the clutch, the main shaft of the transmission stops spinning. -

Actually, fuel wouldn't matter. Should have called it pseudo or alternative dyno. The car is the dyno.

-

Thanks. Sorry to be so blunt. It actually looks like something almost brilliant, after thinking about it, especially considering that it looks like one guy put most of it together. All of the data is there to do a decent calculation, with the AFR determining how much fuel was burned and the rate of RPM increase, along with other variables, being used to determine acceleration. Ideally, of course, you'd be on the Bonneville salt flats with zero wind. But, a flat road on a calm day is pretty close. Thanks for posting. I learned something new.

-

Define load. Load is inertia. Inertia is rate of change of speed. Edit - indirectly. Again, no offense, always nice to try out new stuff. But just because somebody wrote a nice software package doesn't mean it's right. Today's world is full of apps and software and devices and promises that we're all just trusting blindly. The fact that people say it tends to match direct measurements is nice. Just need some verification. And"it's all there in my first post" is a stretch. See image. It's only true if you already know about "Virtual Dyno".

-

You should have noted all of that in your first post, and you should have gotten correct weight, I think. Especially the weight, since the software depends on it. You showed 200 HP and a curve with a description that sounded like a mechanical dyno. It all makes sense, but just like differentiating between the dyno machines, you should do the same with a software "dyno". The basic premise is not really like a mechanical dyno, it depends on many more variables. Each variable can introduce error. Even something simple like the wrong speedo gear, I assume. The software must use speed to calculate acceleration. Have you had your speedo calibrated?

-

No offense intended Gollum. It does make one nervous though.

-

A guy wrote some software and, apparently, many people are downloading it. But, not understanding how it works. Could be ransomware. Weird! https://barnhill.bitbucket.io/ http://www.bradbarnhill.com/ This is the explanation for "What is Virtual Dyno?". No explanation.

-

First I've heard of it. A Google turns up a web site that clicks through to a different address. Can't find a straight answer about how it works. So, how does it work? https://www.google.com/search?source=hp&ei=wOh5XPCiO4bV-gSH1J6ABA&q=virtual+dyno&btnK=Google+Search&oq=virtual+dyno&gs_l=psy-ab.3..0l10.1519.4254..4643...0.0..0.57.545.12......0....1..gws-wiz.....0..0i131j0i10.yDoexiGlHOM

-

Are you using one of those accelerometer iphone apps? They're neat but not sure that they really count for much. No offense. Lots of potential error. Probably good for maximizing a tune but the power numbers will be suspect.

-

You beat me to it...

-

You might look at the other end of the wire to see what it does. Always a good idea when working with wiring.

-

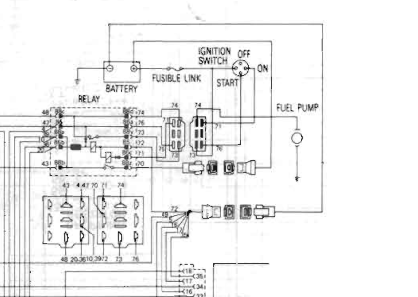

All of the plugs are white. There's a bunch. Might be one of these. Nissan draws the correct plug shape in their diagrams. The full size diagram has wire colors.

-

You can tell if the diff is right because the half-shafts will be perpendicular with the wheels. You can shim the GM mount downward to get the right angle. With the KA transmission (71C) the short propeller shaft will be correct. You moved the diff back, so the shaft needs to be lengthened, not shortened, to use the stock transmission. So an RT mount with GM mount, shimmed downward, and the short propeller shaft with a 71C swap should get everything right.

-

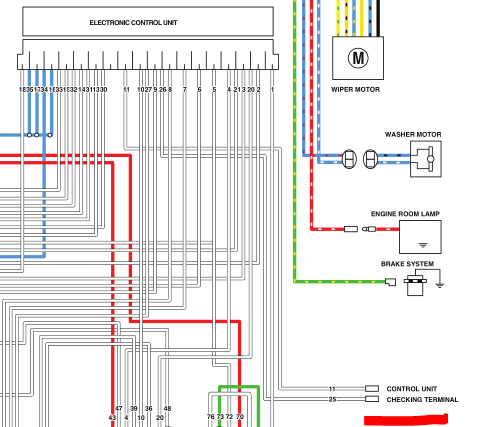

Not used. "Control unit checking terminal". They just hang there and confuse all of us that run across them.

-

Might be easier for you to just get the GM transmission mount and hang the diff from your Technoversion R/T mount. Even with the snubber you can still get some thumping as the diff nose moves up and down. But you might have a new problem, in that your propeller shaft is not as engaged as it was. It's pulled out of the transmission by that /12 inch you mentioned. Better check spline engagement.

-

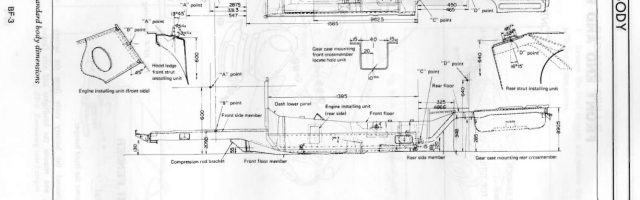

Put the old one back on and see if you still have the problem. Compare the old one to the new one. Check the body chapter for dimensions.