NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

Here's the Rule I was remembering. It only matters though f the guy is still in business, or cares about being on Hybridz.

-

-

Some of the new/reman ones come with the clevis. You might try your local auto parts store. I think that I just threw one in the recycle bin a couple months ago. I might have one in a parts box. What part of PNW? Close to Portland? https://www.rockauto.com/en/catalog/nissan,1976,280z,2.8l+l6,1209226,transmission-manual,clutch+master+cylinder,1996 The Tilton does not come with a clevis?

-

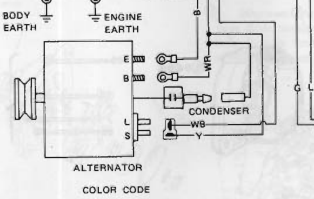

The leg of the T should be white with a black stripe by the diagram. The other should be yellow. The WB wire is the one that should control your charge light. Not sure what's happening when you jump it like that, it shouldn't really do anything. It might be that you're running full current through a short in the alternator. The charge light is actually a resistor that controls current flow through that circuit. Kind of sounds like you have two problems - a bad connection to the BAT terminal, and a bad alternator. Parts store alternators have been known to be bad out of the box. I'd get it tested.

-

I think that shows a high resistance in the line from the BAT terminal to the battery. That cable runs to the starter lug, then the positive cable runs up to the battery. Could just be a loose connection at the starter terminal or bad positive connection at the battery. It's a good test though, you have a problem somewhere along the way. Forgot about the black fusible link also. It could be bad or have a bad connection. It's on the way to the battery from the BAT terminal.

-

You can report them to the Better Business Bureau if they are a licensed business. Hybridz used to have some things about Vendors and how they would deal with the bad ones. But the Rules and Guidelines aren't available anymore.

-

I think that Motorsport Auto used to sell their own brand of lowering springs that were blue. Nissan/Datsun springs are black with a colored paint splotch on them. The springs aren't really difficult to change. The 240Z's have enough room to swing the strut out and take the top off, without disconnecting the control arm. Once you get started though you usually find a bunch of other stuff that needs doing.

-

Hey @RETRO-SPEC

-

Here's two thoughts - 1. Check voltage at the coil. Maybe your voltage regulator is going bad and "over-volting" things. I don't know how a tach would react to that but it's a possibility. 2. Spend $25 for a GM HEI module and wire it in quick and dirty. It might actually make things worse, sometimes they cause their own tach problems, but it might tell you something. Always good to have a backup ignition module anyway, the 40+ year old modules die on a regular basis. Two cheap checks, compared to new gauges. Good luck.

-

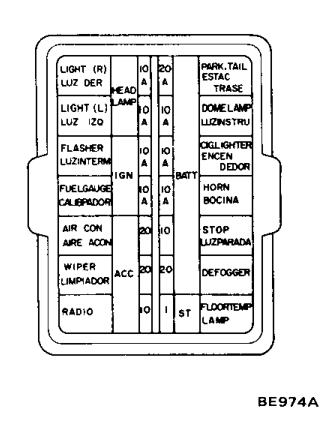

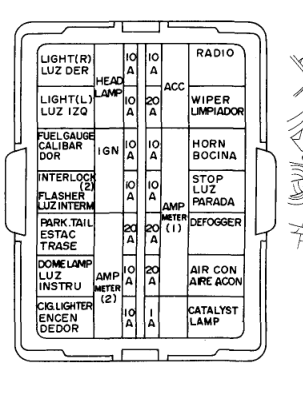

Does it match RPM? Could be a sign of a failing ignition module. If the flasher makes noise then it must be getting voltage. Current flow heats and cools the mechanism. Always possible that the bulbs are burned out. Also, check the grounds. Can't remember if the tach signal lights have their own ground wire from the socket or if they ground through the socket to the tach body. Who knows, poor ground might also be the problem with the tach needle. The ground circuit is often overlooked. I've also found that the bulbs and sockets can be pretty touchy. They have to be just right and are easily knocked loose. Once you get in there sometimes the problems just grow. I got the fuse cover picture from the 75 FSM. You might have a more 76 like system. 75 had a lot of firsts, and new changes. Here's 76.

-

My mistake, I was thinking clevis pin. You could cut the rod in the middle and insert a tall nut, maybe. Or put a bolt/screw through the back of the clevis and use the tall nut as an extension. Spitballing... Example - https://us.misumi-ec.com/vona2/detail/221005295770/?rid=rid3

-

You should find a shop that knows Z cars and Quaifes. The wrong shop could waste a lot of your time. There are many people out there that are happy to guess, on your time and money. The "clip" problem is pretty well known by people that have worked on the Datsun diffs. A 510 shop would probably know also.

-

That's the basic problem, I think, the groove shapes are different. Nissan changed the location of the clips around the time that they introduced the VLSD diffs. If you get a VLSD diff, like from a 90's Nissan, the clips will come out with the axle. If you have an early open or CLSD diff the clips stay inside. I think that if you get two square grooves combined you could end up with a stuck axle. Better inspect things closely. Your shop is probably use to looking at VLSD's like on the 240SX. There is a lot of confusion on the CV axles. Some places even show the 240Z's used CV axles. There's bad data out there.

-

Looks like they changed over the years. #10? Might be available from Nissan. http://www.carpartsmanual.com/datsun/Z-1969-1978/brake/brake-clutch-pedal https://www.courtesyparts.com/oem-parts/nissan-pin-clevis-46123h850a

-

Most strut/insert manufacturers recommend bump stops. Probably in the instructions of whatever you end up getting.

-

RB25 in a 1977 280Z Heater Functionality

NewZed replied to SelectSpeedShop's topic in Nissan RB Forum

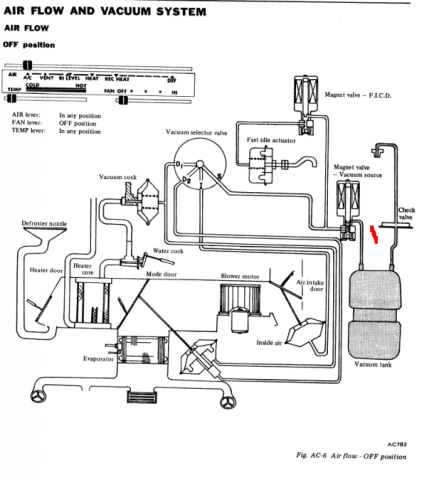

Connecting direct to S might work. There is an electric connection in the switch that opens and closes that first magnet valve. It's described in the chapter. Not clear what would happen if you still have vacuum when you turn the heat to Off. I can't remember what actuates the first magnet valve. Without a vacuum bottle the valves will open and close with engine vacuum, probably, even with a check valve. Cold feet on the on-ramps. -

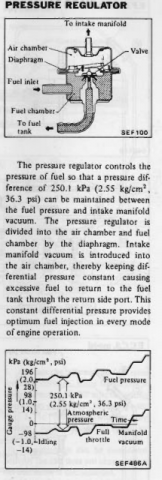

It's 36.3. You should check between filter and rail. If you're getting 60-70 before the filter you might have a clogged filter. But, in short, no offense...you're doing things wrong. Stop the random stuff and get in to the FSM or the EFI Book and do things the recommended way. You'll save time in the long run.

-

RB25 in a 1977 280Z Heater Functionality

NewZed replied to SelectSpeedShop's topic in Nissan RB Forum

zhoob he doesn't have the mechanism to control the coolant flow or the air flow. Both are vacuum controlled. No vacuum, no heat. I had a vacuum hose that used to split on a fairly regular basis. I would know immediately that the hose had split because the heat would stop. No vacuum, no heat. -

These early EFI systems need the basics to be right-on for everything else to work right. Guessing won't work. Get the 1980 EFI Book, or the 1983 Service Manual (FSM) and make things right. Your fuel pressure is way too high, for starters.

-

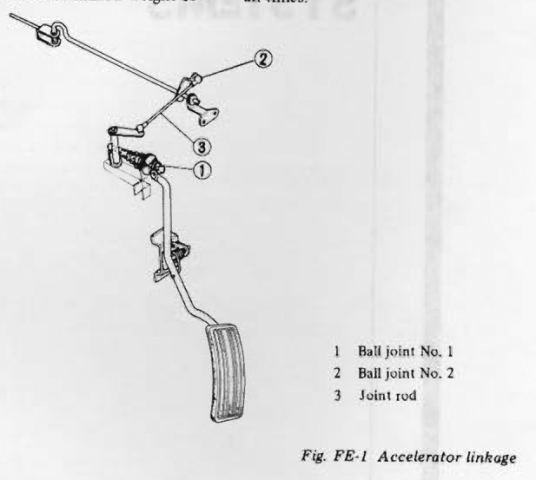

This part is actually the joint between the two rods. They put it together backwards then got confused. Pop it apart there and flip it over. You'll need to remove the hooked portion at the end to get it free. It's supposed to slide, I don't know why they put those hose clamps on there unless it's too short. Your 280Z manifold might have a longer rod that you can swap over. Take it apart and put it back together with more puzzle pieces.

- 8 replies

-

- l28

- engineswap

-

(and 1 more)

Tagged with:

-

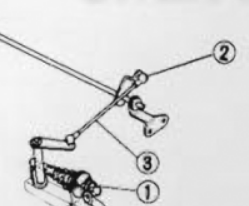

It looks like they put #2 on the bottom instead of the top. Pressing the pedal would close the throttle not open it. Does the engine run? Does the pedal work at all? Looks backward. It's messed up, but probably fixable.

- 8 replies

-

- l28

- engineswap

-

(and 1 more)

Tagged with:

-

It looks like somebody could probably make that work. Easier than swapping intake manifolds. There is a lot of adjustability in those rods. Take a close look and you'll see that they are threaded on the ends. Pop the plastic end off of the joint and you can screw the ball in or out to make the rod longer. The wood piece makes me think that they broke something when they did the swap. That's a hack job. There's a bracket there that should hold up that end of the linkage.

- 8 replies

-

- l28

- engineswap

-

(and 1 more)

Tagged with:

-

Sounds like a vacuum leak. Check your hoses.

-

RB25 in a 1977 280Z Heater Functionality

NewZed replied to SelectSpeedShop's topic in Nissan RB Forum

The RB wouldn't have anything to do with the heater functions, compared to the L6. All it does is supply the hot coolant and the vacuum. You need those valves. Not much you can do except put it back like it was, or study the diagrams and make it work. There's no tricks. The AC chapter has the good drawings and descriptions. Some of the controls are mechanical and some are vacuum operated.