NewZed

Members-

Posts

6700 -

Joined

-

Last visited

-

Days Won

72

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by NewZed

-

There is a common problem with bolt size versus hole size that is solvable. But you haven't given enough information to know what you're looking for. Good luck bud.

-

Just checking the new guy's sense of humor. There is none, apparently. Good luck.

-

Do you have to write so much? Really hard to get through the message. What makes you think the ring gear will not bolt to the carrier? (I translated your words down to what I think you meant to write). Your options would be to get a different LSD, of course, that fits your ring gear. Or a different R200 to do the swap in. p.s. pictures are always a good thing.

-

If it's an early 260Z or a 240Z then the stub axles in the rear hubs might be the weak link. Theu-joint half shafts seem pretty tough, many guys keep them on their V8 swaps. But the side loads you'll put on the hub axles will be high. Don't the drifter guys run high air pressure on hard compound tires? It's not like you're maximizing traction for drag racing. When you weld the spider gears to the carrier you essentially make a solid axle. The things that used to spin and break don't spin any more. There are old threads about guys needing to modify the steering to drift. The Z's don't have much range lock-to-lock. They don't drift well. The diff is probably the least of your issues.

-

Looks like he just swaps flanges. I wonder if he is just cutting flanges off old u-joint axles and welding them on to "CV" axles. I can't remember all of the different types, but I think those are "tripod" axle ends. Not "real" constant velocity joints. I would want to know how he aligns the flanges before welding to be sure that they're centered correctly. He advertises smoother operation but it won't be smooth if there's any misalignment. He also says that the axles are "sourceable" but he must mean the center piece/shaft. The housings, with flanges, are going to be one-off pieces, available only from him. Nice find, interesting product. Not sure that they're much better than a u-joint axle though. What's the benefit?

-

Battery died now car won't start

NewZed replied to Senor_Grizzly's topic in S30 Series - 240z, 260z, 280z

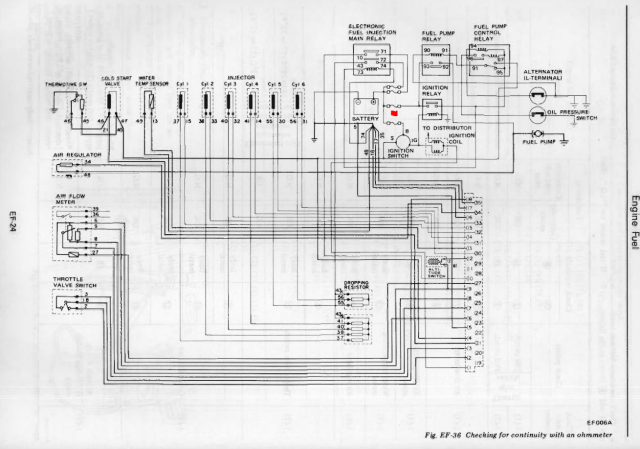

First, you need to learn a little bit about electricity. Get a test light or a multimeter. It's not that hard, there are you tube videos about it. Second, learn what the words mean. "Crank" means "turn over". The first cars had a hand crank to turn the crankshaft. You probably mean "fire" or "start" when you say turn over. So, what you're saying is that when you turn the key to Start the engine "turns over" but does not start. But it smells like gas. The problem with the coolant temperature sensor might be a clue. If the sensor does not have a good connection or if it does not work the ECU will add lots of extra fuel. You might have flooded the engine. Remove a spark plug and see if it is wet with gasoline. The best way to test the coolant temperature circuit is with a multimeter at the ECU connector. Measure resistance. Compare resistnace to the number on the chart in the FSM or the EFI Book. Use the book to find the proper pins. It covers all years through 1980. https://www.classiczcars.com/files/file/32-efi-book-1980/ -

Colorado? https://row52.com/Vehicle/Index/RNDiNHqxcPgtRlnNS5qL6cmDf

-

Here's one for $8000. Or he might let you take a picture. https://sacramento.craigslist.org/cto/d/chico-1975-datsun-280z/6789601347.html

-

1978 satay fuel problem cranks but wont start

NewZed replied to Tito's topic in S30 Series - 240z, 260z, 280z

You're jumping around from idea to idea. Follow the power from the battery to the pump. Come back and post where you last saw voltage. The "Ign" fusible link then pin 93 of the fuel pump relay are your first two spots to check. -

problem Whining on acceleration

NewZed replied to youztheclue's topic in S30 Series - 240z, 260z, 280z

Here's a good "71C" writeup from a Hybridz member. R200 swap info is all over the internet. https://www.motortopia.com/members/Nigel/mediapress/240sx-transmission-swap-14041/- 6 replies

-

- 260z

- transmission

-

(and 1 more)

Tagged with:

-

What happened to it? Is the site going the way of zcar? Odd problems seem to be building up.

-

I don't know the details of the 92 TT. I had a 95 Pathfinder though and it's belt was good for 100,000. The earlier VG30E models were good for 60,000 I think. 27,000 is almost new in either case. Yours is the rounded tooth variety which is the 100,000 mile design, the others had squared teeth. Doesn't seem like belt wear would be the issue. The fact that one cylinder climbed to 150 suggests that the valve timing is close enough, since they're all tied to the same belt. Probably bent valves or broken piston/rings on the bad ones. Turbos tend to damage pistons. You still might check the rocker arms and lifters though. I don't know if the hydraulic lifters leak down enough to keep the valves from opening. That would give a low pressure reading because no air gets drawn in, because the valves don't open. Is their oil in the crankcase? Dip stick at full? Most cylinder pressure gauges have a valve that needs to be opened to release the pressure between tests. Not sure that just leaving the gauge on will tell you about leak down, it will just read the last highest pressure in the gauge. You're supposed to pressurize the cylinder using an external air supply for a leak down test. Sounds like you definitely have dead and damaged cylinders though. Doesn't look like readjusting the timing belt is going to fix your problem. If you've already been spinning the engine maybe you should just put it back together and start it on the remaining cylinders. It will run like crap but it's messed up anyway.

-

The belt seems close and the numbers are very low. But if it's been sitting in a field for years the cylinders might be rusty. Adding oil to the cylinders would make that problem better. You could remove a valve cover and look at rocker arms and valve ends. You could also do a leak down test. The belt doesn't look terrible. Seems more likely that somebody just did a poor job on a belt change or some maintenance work. I think that they're usually much more worn when they slip. The teeth wear out or break off.

-

Here's a database that might have something. A pain to work through, very clunky, and not intuitive https://parts.nissanusa.com/nissanparts/index.cfm?setvin=&bodyColor=&trimColor=&BODY=CALC&ENGINE=KA24DE&TRIMLVL=SE&TRANS=MT&action=replacement&setAttributes=true&jointvehid=9359&siteid=14&groupid=F§ionid=320

-

-

It might help to get in to the details of how the bleeder screws work. There's a narrow cone shaped seat on the bottom of the screw that plugs the hole in the caliper. When you loosen the screw the fluid is released and flows in to the small hole next to the screw seat then up through the middle of the bleeder screw. All that matters for stopping leaks is how the cone shaped seat fits in to the hole. Reman calipers often have poor seats for the screw. So inspect the hole carefully, and make sure that the seats are clean and smooth. You should not have to tighten the screws very much if the sealing surfaces are in good shape. Here's a picture I stole from the internet and where I got it. I don't know if I agree with the guy but he takes a good picture. I added some red lines to show the gouge in the screw from where it seats in the caliper. http://www.eatsleeptinker.com/2014/05/15/brake-bleed-valves/

-

If you don't define it then you're kind of just throwing it around like everyone else. "Military" does not necessarily mean "high quality". Most of us respect the military, but "mil spec" is just another standard set of specifications. To be precise you need to give the spec number. "mil spec" for a desk lamp might not be the spec you're looking for. https://en.wikipedia.org/wiki/United_States_Military_Standard

-

Still....

-

I see now that he's in the FAQ section. I thought that this problem was going to be fixed. People can start new threads but nobody can reply. Doesn't make sense. His first two posts had "too many redirects" and wouldn't open even though they were in the right place.

-

The headlight dimmer switches get gummed up on these old cars and stop the headlights from working. You can spray contact cleaner in to the base of the stalk and work it back and forth and they might start working. Or the fuses could be blown. There are several places on the internet where you can download a service manual. You should do that, they're very thorough. What's up with the drill motor? Is it for scale?

- 5 replies

-

- craigslist

- 280z

-

(and 2 more)

Tagged with:

-

Three separate thread attempts, two of them wouldn't open, the third has no means to reply.

-

What are your plans? "runs" doesn't seem like much to make a choice on. Pick the one that has least amount of the type of work you hate.

-

Strut mods. How far off base am I

NewZed replied to rabrooks's topic in Brakes, Wheels, Suspension and Chassis

Isn't the "cooling fluid" thing just a myth. Some strut manufacturers recommend against it. https://www.kyb.com/knowledge-center/shock-tech-for-pros/installation-tips/strut-cartridge-installation/ The same struts are often spec'ed for both 240Z and 280Z. The difference is the length in the back. https://www.rockauto.com/en/catalog/nissan,1978,280z,2.8l+l6,1209260,suspension,strut,7584 https://www.rockauto.com/en/catalog/nissan,1972,240z,2.4l+l6,1209169,suspension,strut,7584 If a person considers the basics of what the gland nut does when a cartridge is used, things get simpler. It just centers the cartridge and applies clamping force. Shims and collars can be sued to make gland nut cavity smaller, or a lathe to make it bigger. Just some thoughts. It's just a shock absorber in a tube if you use the original strut tubes.